Clamp for scraping and impacting composite rock breaking test

A fixture and rock-breaking technology, which is applied in the field of scraping and impact combined rock-breaking test fixture device, to achieve the effect of reducing test cost, high frequency and fast action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with accompanying drawing:

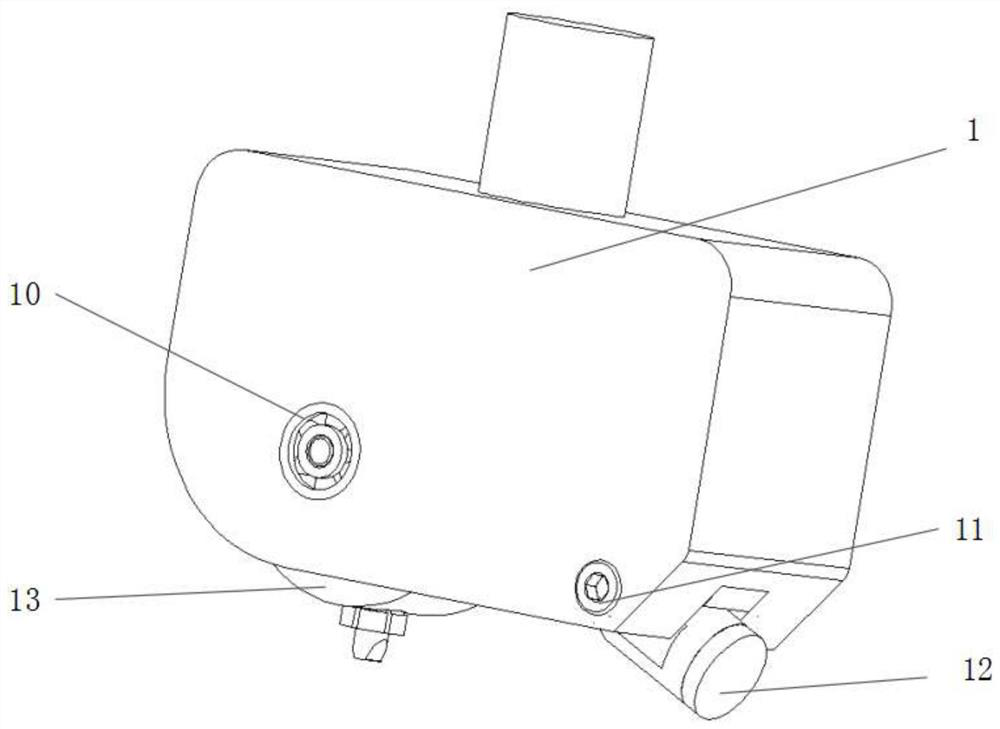

[0025] Such as figure 1 As shown, a fixture for scraping and impact composite rock breaking test of the present invention is mainly composed of fixture main body 1, bearing 10, hexagon socket bolt 11, PDC tooth 12, and gear hobbing fixture 13.

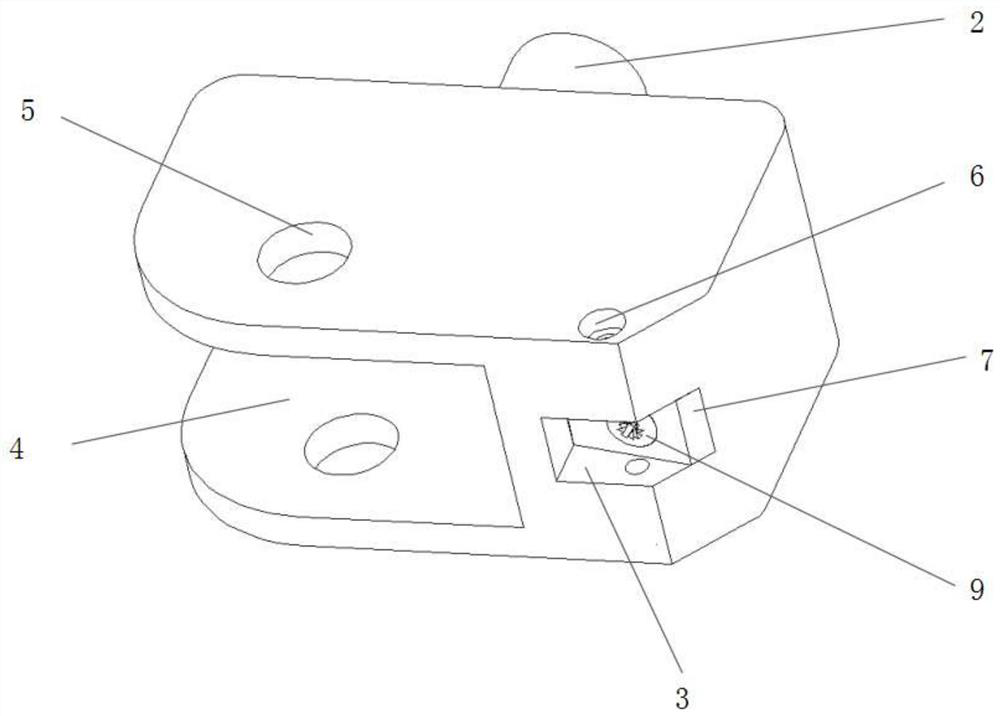

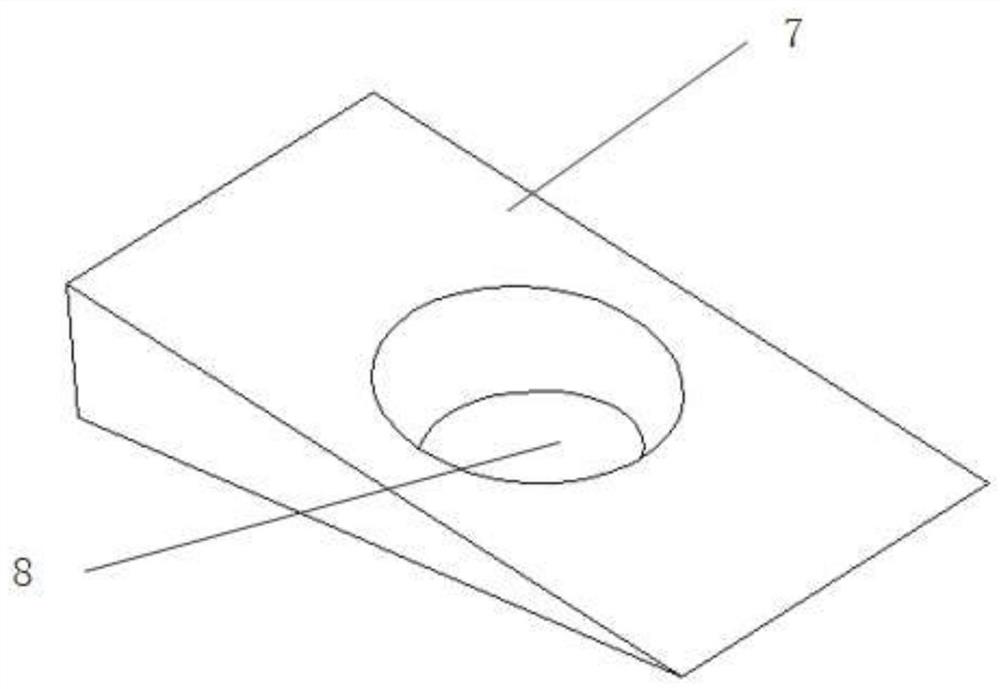

[0026] Such as figure 2 , image 3 As shown, the fixture main body 1 is composed of a clamp handle 2, a PDC tooth installation groove 3, a gear hobbing fixture installation groove 4, two bearing installation holes 5, two countersunk threaded holes 6, an angle pad 7, and a bolt 9. The countersunk threaded holes 6 opened on both sides of the PDC tooth installation groove 4 cooperate with the hexagon socket bolt 11, and the PDC tooth 12 is fixed in the PDC tooth installation groove 3 by rotating and adjusting the hexagon socket bolt 11; The angle pad 7 is fixedly installed at the bottom of the PDC tooth installation groove 5, and differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com