A hardness testing device for optical glass production

A technology of optical glass and detection device, which is applied in the direction of measuring device, testing material hardness, scientific instruments, etc., can solve the problem of inability to change the drop height and drop position of the falling ball, inability to detect the impact resistance hardness of optical glass, replenishment and reuse, etc. problem, to achieve the effect of saving the time of picking up and placing the falling ball, increasing the accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

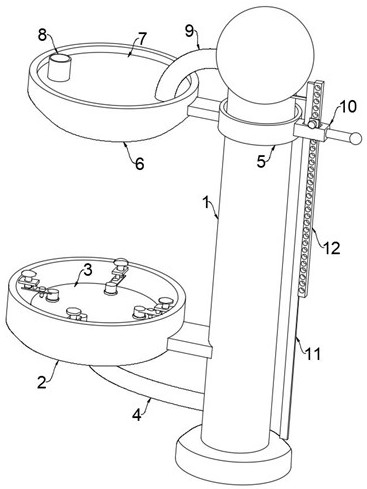

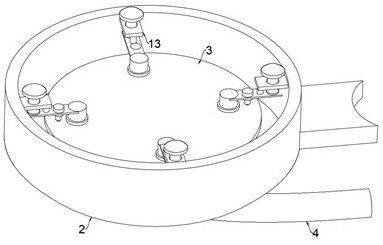

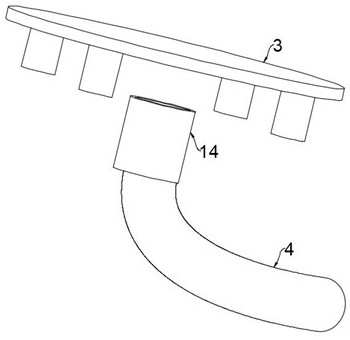

[0036] refer to Figure 1-4 , a hardness detection device for optical glass production, comprising a column 1, a feeding tube 4 is installed on the column 1 through a bearing mechanism;

[0037] The above points worth noting are the following:

[0038] 1. The carrying mechanism includes a carrying plate 2 fixedly installed on the column 1. A supporting plate 3 is fixedly installed on the carrying plate 2 through a plurality of support columns. A connecting pipe 14 is fixedly installed on the carrying plate 2, and the connecting pipe 14 is connected with the blanking plate. The tubes 4 are connected, and a plurality of fixed plates 13 are fixedly installed on the carrier plate 2, and each fixed plate 13 is equipped with a moving plate 17 through a pressing structure.

[0039] 2. The pressing structure includes a threaded rod 15 threadedly installed on the fixed plate 13. The bottom of the threaded rod 15 is fixedly installed with a limit rotating shaft 16, and the moving plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com