Windshield durability testing device

A technology of testing device and windshield, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of uneven aerodynamic load, small range of pneumatic pressure differential load, and low control accuracy of load change, etc. Achieve the effect of ensuring low temperature impact effect, accurate test results and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

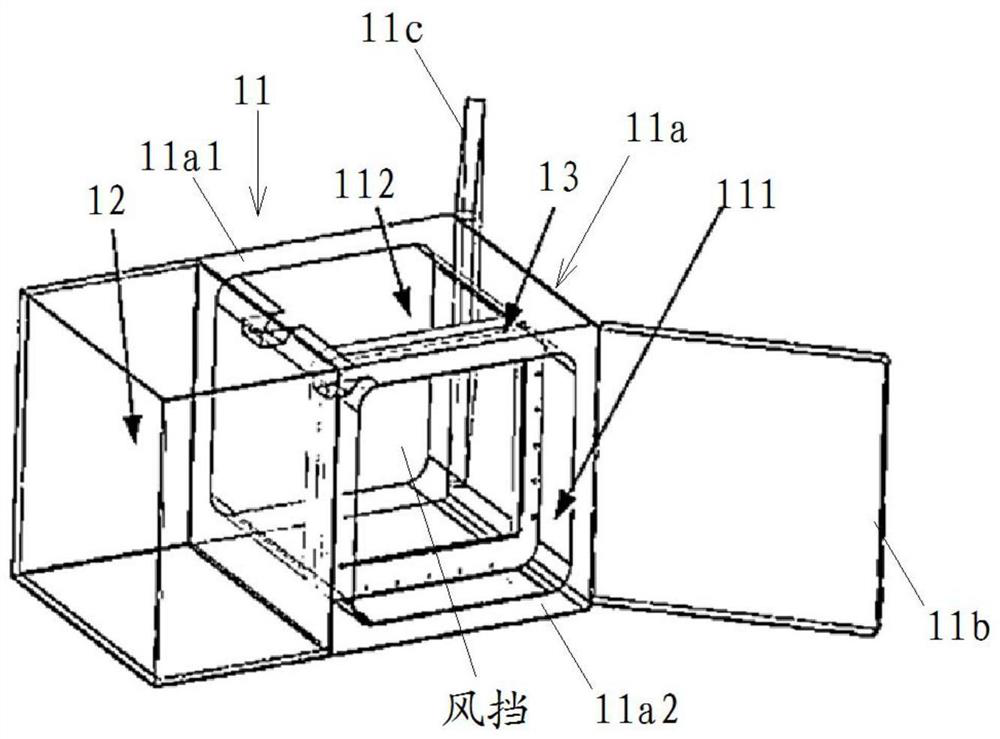

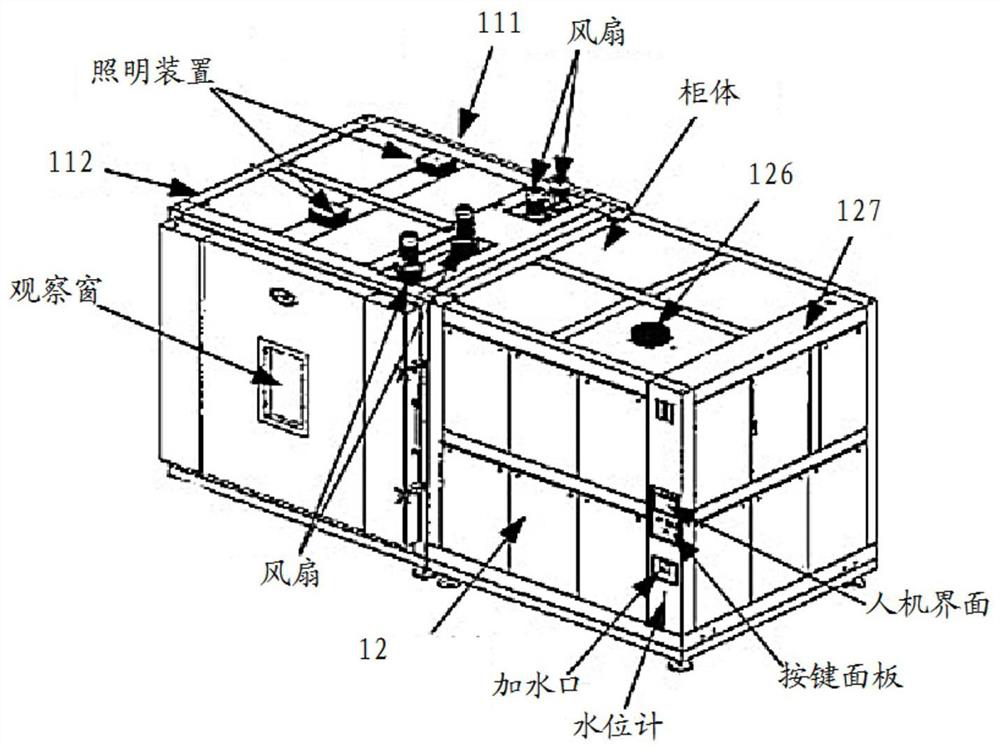

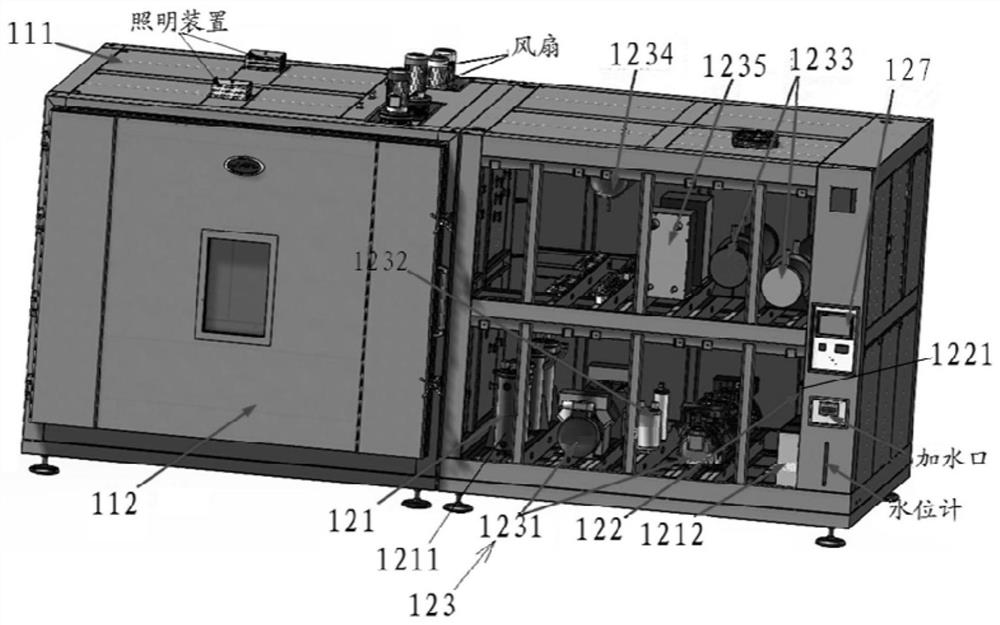

[0071] Such as figure 1 As shown, according to an embodiment of the present invention, a windshield durability testing device of the present invention includes: a test box 11 , a clamping device 13 for clamping the windshield, and a control system 12 connected to the test box 11 . In this embodiment, the test chamber 11 includes: a first working chamber 111 and a second working chamber 112 ; the clamping device 13 is located between the first working chamber 111 and the second working chamber 112 .

[0072] By arranging the clamping device 13 in the test box, the durability test of the windshield in a closed environment can be realized, and the influence of the external environment on the test accuracy can be effectively eliminated. At the same time, the method of setting the clamping device in the test box can also realize the simulation of different actual application environments on the inside and outside of the windshield, so that the test results are closer to reality and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com