Infrared lock-in thermography defect identification method for honeycomb sandwich structure

A technology of infrared phase-locking and honeycomb interlayer, applied in the direction of material defect testing, etc., can solve problems such as difficult to effectively determine the detection process of products with different structures, thicknesses, and sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0174] The following detailed description will be further described below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are only used to explain the relevant invention, not the limitation of the invention. It will also be noted that only portions associated with the relevant invention are shown in the drawings for ease of description.

[0175] It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict. The present application will be described in detail below with reference to the accompanying drawings.

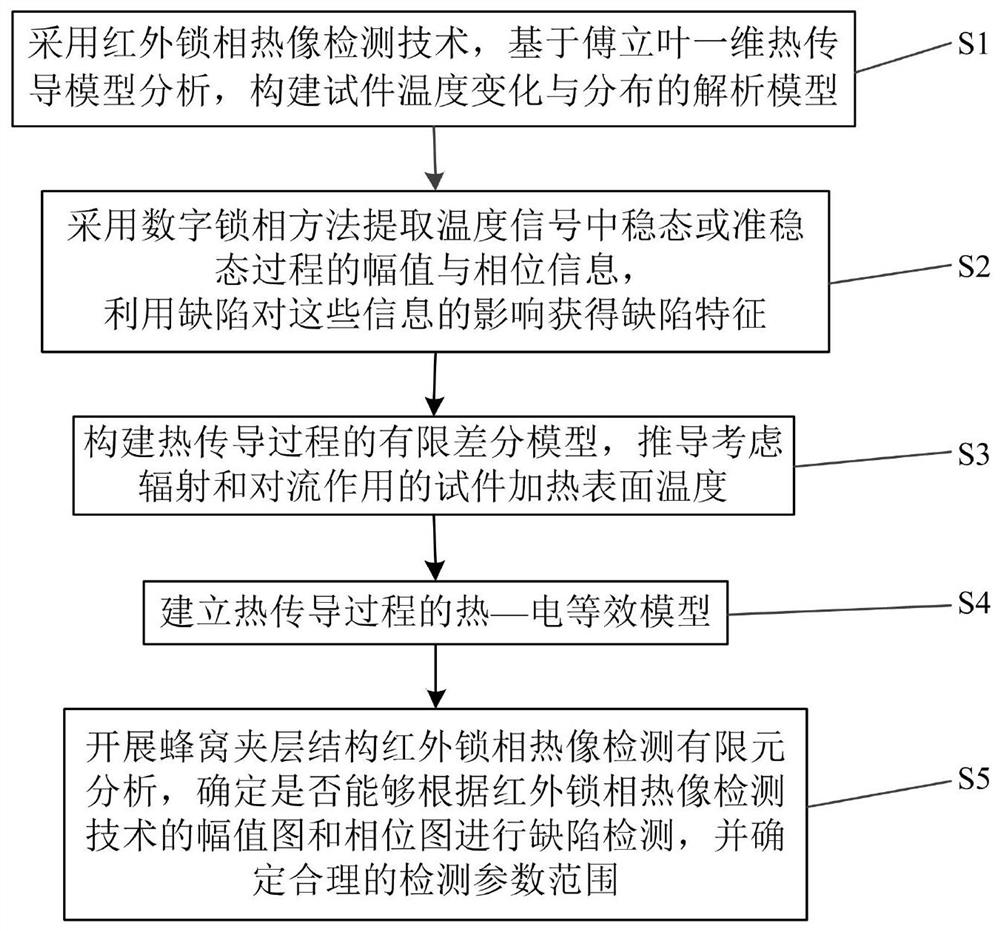

[0176] figure 1 An infrared lock-sensing imaging defect recognition method for a honeycomb interlayer structure is shown in the present invention comprising the steps of:

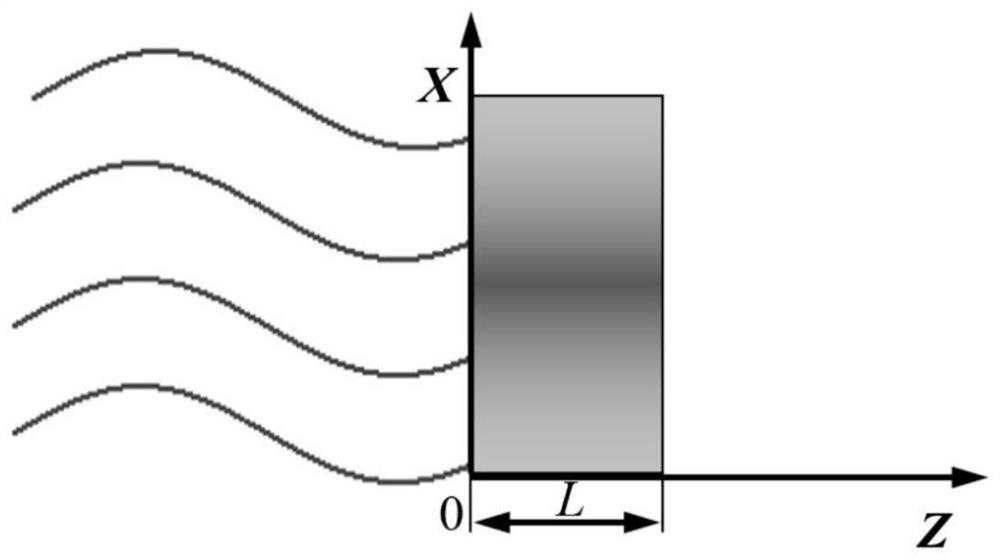

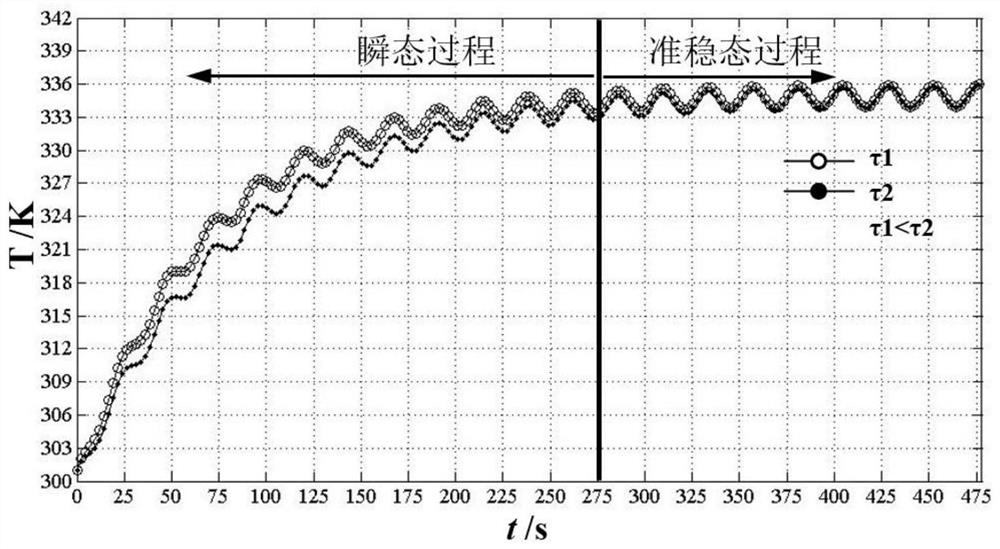

[0177] S1, using infrared lock phase heat imaging detection technology, based on Fourier one-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com