Wind turbine blade damage positioning detection method

A wind turbine blade and damage location technology, which is applied to measuring devices, processing detected response signals, and using sonic/ultrasonic/infrasonic waves to analyze solids, etc. The effect of convenient blade design, shortening time and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

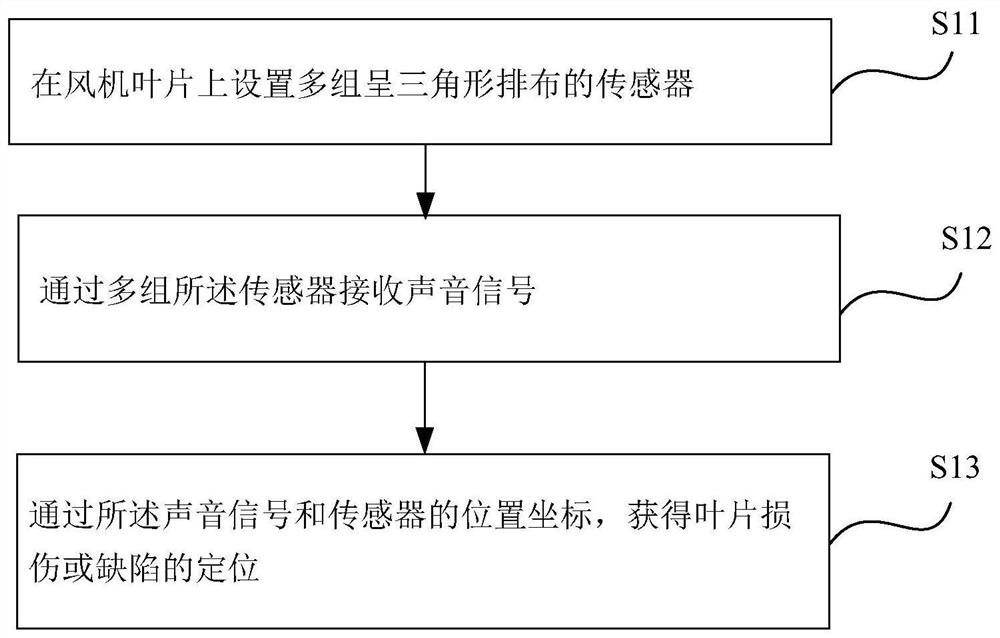

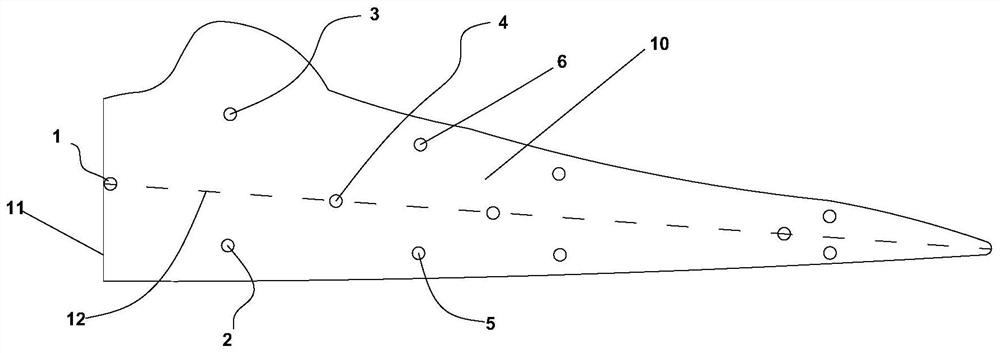

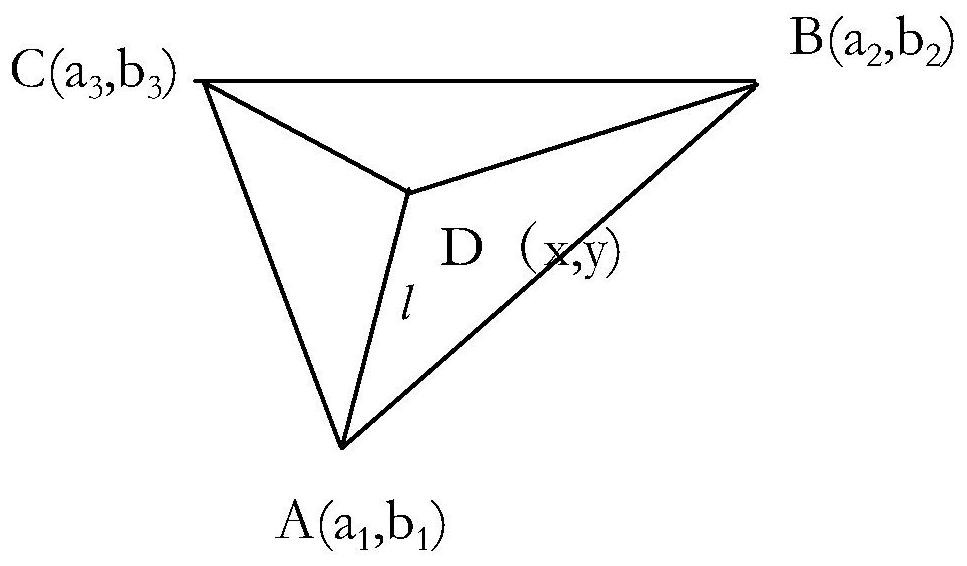

[0070] A wind turbine blade damage location detection method can quickly locate the damage or defect location by collecting and processing the sound generated by the damage or defect during the blade movement. The sound generated by the damaged part during the movement of the blade is collected by the sound sensor to obtain the location of the damaged part. Then, when the fan blade is stationary, use the phased array ultrasonic testing equipment to scan and detect the blade surface in the positioning area to quickly understand the defect type of the blade And the damage situation, at the same time, according to the comparison of the detection results and the sound signal, the sound source signal is classified according to the defect type, and the defect sound database is established. Taking the blade suction side as an example, the pressure side method is the same. The sensors are arranged in a triangular manner on the suction surface of the blade. From the root of the blade t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com