Slow-release electrolyte, preparation thereof and application of slow-release electrolyte in lithium ion battery

An electrolyte and slow-release technology, which is applied in the field of lithium-ion batteries, can solve the problems of difficulty in electrolyte replenishment, achieve the effects of increasing performance, maintaining wetness, and slowing down collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

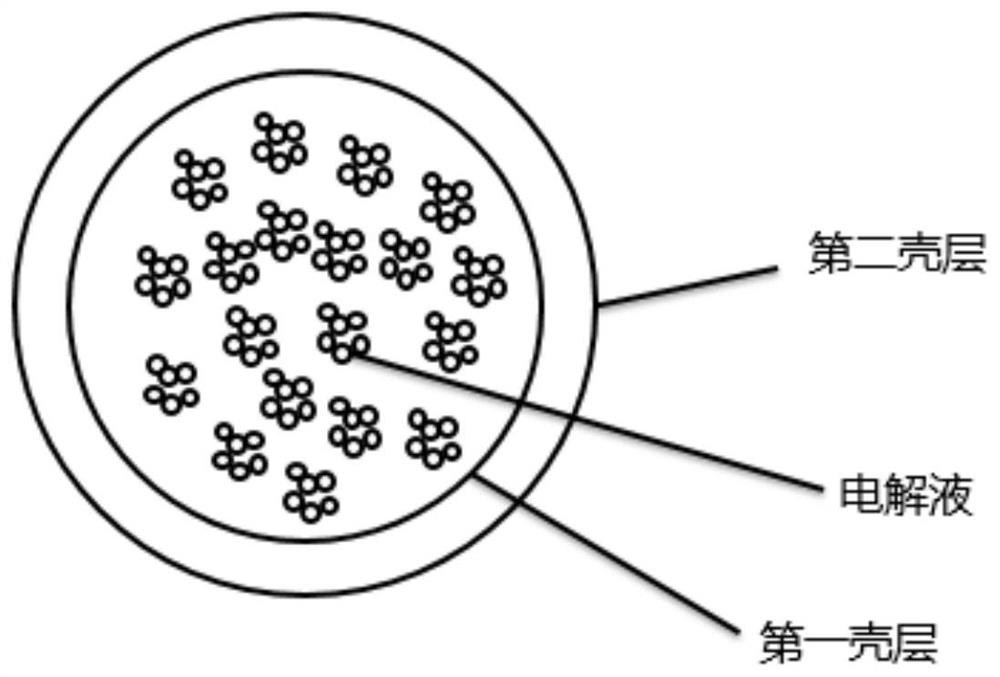

[0047] (1) slow release electrolyte

[0048] Mix a formaldehyde solution with a mass concentration of 37% (including 150g formaldehyde) and 200g melamine, add 5gNaOH, heat up to 60°C, react for 240min, remove water under low pressure (less than 0.1Pa), and prepare a melamine formaldehyde resin with a molecular weight of 50,000 to 100,000;

[0049] Mix 37% formaldehyde aqueous solution (including 100g formaldehyde) and 200g melamine, add 5gNaOH, heat up to 60°C, react for 240min, remove water under low pressure (less than 0.1Pa), and prepare melamine formaldehyde resin with a molecular weight of 100000-150000;

[0050] Mix 300 g of the melamine formaldehyde resin with a molecular weight of 50,000 to 100,000 prepared above and 100 g of electrolyte (EC:DEC:PP=3:3:4 (volume ratio), lithium hexafluorophosphate whose lithium salt is 1 mol / L) in a reactor , place the whole reactor in an environment with humidity <30% RH and temperature <20°C, then raise the temperature of the reactor...

Embodiment 2

[0061] Other operations are with embodiment 1, difference is in the step (4):

[0062] Disperse 25wt% of the above-mentioned slow-release electrolyte, 64wt% alumina, 7wt% binder SBR, and 4wt% dispersant CMC in water, stir and coat evenly on the surface of one side of a 5 μm thick polyethylene diaphragm substrate, Dry to obtain a diaphragm coated with a ceramic layer with a thickness of 2 μm on one side; disperse the binder PVDF in water, stir and coat evenly on both sides of the diaphragm coated with a ceramic layer on one side, and dry to obtain a single-sided coating A diaphragm coated with a ceramic layer and coated with an adhesive layer on both sides (the thickness of the adhesive layer on one side is 1 μm).

Embodiment 3

[0064] Other operations are with embodiment 1, difference is in the step (4):

[0065] Disperse 5wt% of the above-mentioned slow-release electrolyte, 84wt% alumina, 7wt% binder SBR, and 4wt% dispersant CMC in water, stir and evenly coat one side of the polyethylene diaphragm substrate with a thickness of 5 μm. Dry to obtain a diaphragm coated with a ceramic layer with a thickness of 2 μm on one side; disperse the binder PVDF in water, stir and coat evenly on both sides of the diaphragm coated with a ceramic layer on one side, and dry to obtain a single-sided coating Separator with ceramic layer and double-sided adhesive layer (the thickness of the adhesive layer on one side is 1 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com