Plastic package motor for range hood

A technology for plastic-encapsulated motors and range hoods, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of heat dissipation, reduce the safety of plastic-enclosed motors, and reduce the stability of plastic-enclosed motors, so as to increase heat dissipation and improve Safety and stability, to achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

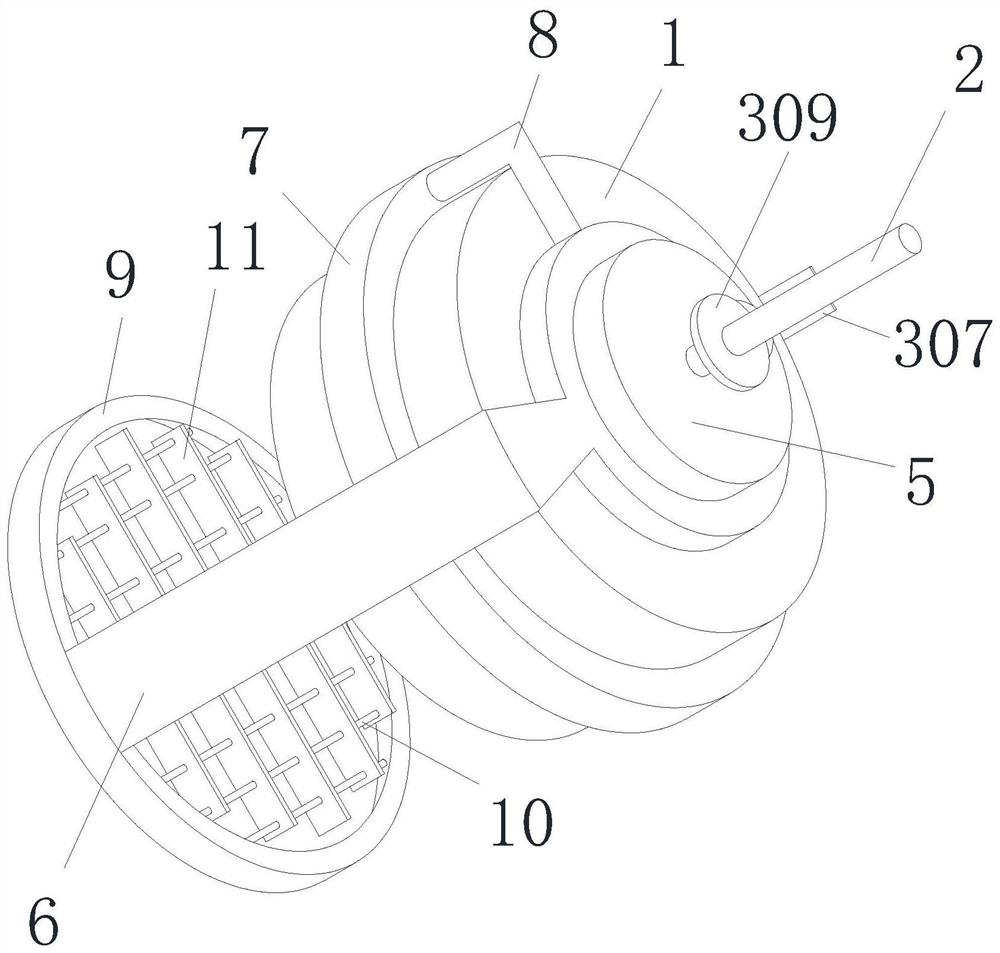

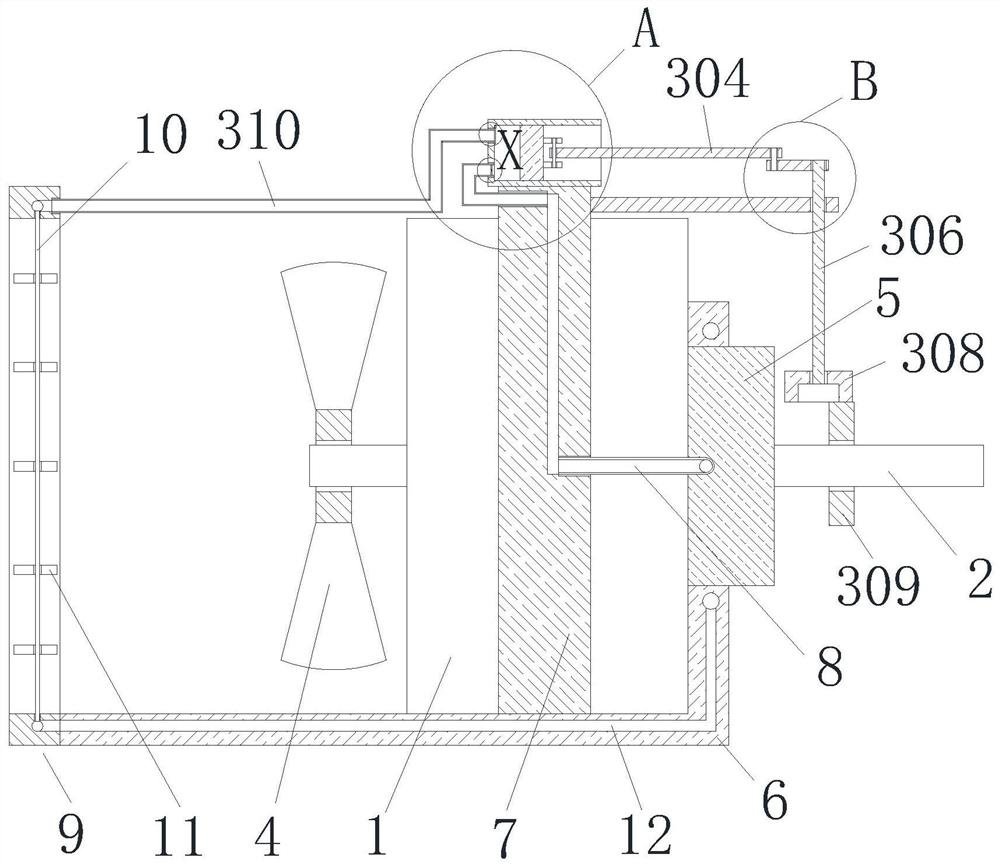

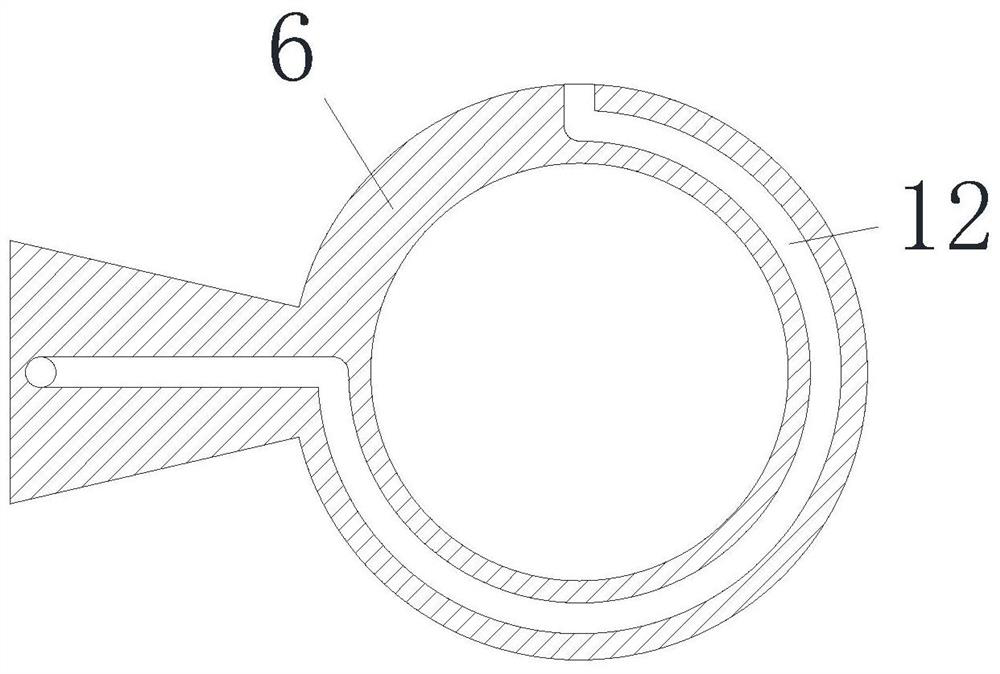

[0029] One kind of plastic hood with a motor, such as: Examples Figure 1 - Figure 9As shown, including the plastic cover 1, the plastic block 1 has a right side movable sleeve into the drive shaft 2, the left end outer wall of the transmission shaft 2 and the left side of the plastic cover 1, and the left end of the drive shaft 2 has a fan. The blade 4, the fan blade 4 is located on the left side of the plastic cover 1, the right end activity of the drive shaft 2 is in a metal cover 5, and the metal cover 5 is a cylindrical structure, and the left outer wall of the metal cover 5 is fixed in the right surface of the plastic cover 1. The metal sleeve 6 is provided below the plastic seal 1, and the left end of the metal sleeve 6 is lapesed, and the right end of the metal sleeve 6 is ring-shaped, and there is a water tank 12, a metal sleeve. 6 The right end fixation is attached to the outer wall of the metal cover 5, and the left side of the metal sleeve 6 is attached to the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com