Tear-resistant series constant power electric heating cable

An electric heating cable, anti-tearing technology, applied in the direction of circuits, insulated cables, electrical components, etc., can solve the problems of low surface energy, non-sticky surface, low friction coefficient, and reduced stability of Teflon F46, and achieve anti-tearing Tear performance, improvement of mechanical strength and toughness, and effect of high stability strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

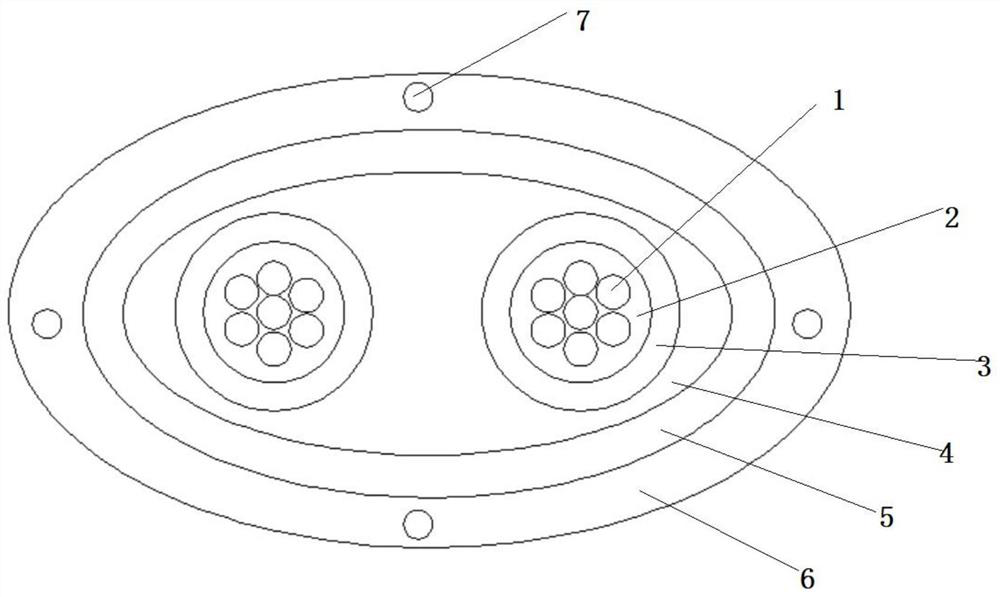

[0022] The tear-resistant series constant power electric heating cable includes two groups of tinned copper conductors 1, each group of tinned copper conductors 1 is wrapped with a low-resistance transition layer 2 and a polyperfluoroethylene propylene insulating layer 3 in turn. The resistance transition layer 2 and the tinned copper conductor of the polyperfluoroethylene propylene insulating layer 3 are jointly wrapped with a PTC layer 4, the PTC layer 4 is wrapped with a tear-resistant mixed braided layer 5, and the tear-resistant mixed braided layer 5 is wrapped with a The reinforcing sheath layer 6 is provided with a plurality of channels along the axial direction, and each channel is filled with a high-strength aramid yarn filling rope 7 .

[0023] The tear-resistant hybrid woven layer 5 is woven from carbon fiber and glass fiber.

[0024] The reinforced sheath layer is composed of the following raw materials in parts by weight:

[0025] Trimethylolpropane 3, polyperflu...

Embodiment 2

[0033] The tear-resistant series constant power electric heating cable includes two groups of tinned copper conductors 1, each group of tinned copper conductors 1 is wrapped with a low-resistance transition layer 2 and a polyperfluoroethylene propylene insulating layer 3 in turn. The resistance transition layer 2 and the tinned copper conductor of the polyperfluoroethylene propylene insulating layer 3 are jointly wrapped with a PTC layer 4, the PTC layer 4 is wrapped with a tear-resistant mixed braided layer 5, and the tear-resistant mixed braided layer 5 is wrapped with a The reinforcing sheath layer 6 is provided with a plurality of channels along the axial direction, and each channel is filled with a high-strength aramid yarn filling rope 7 .

[0034] The tear-resistant hybrid woven layer 5 is woven from carbon fiber and glass fiber.

[0035] The reinforcing sheath layer is composed of the following raw materials in parts by weight:

[0036] Trimethylolpropane 4, polyperfl...

Embodiment 3

[0044] The tear-resistant series constant power electric heating cable includes two groups of tinned copper conductors 1, each group of tinned copper conductors 1 is wrapped with a low-resistance transition layer 2 and a polyperfluoroethylene propylene insulating layer 3 in turn. The resistance transition layer 2 and the tinned copper conductor of the polyperfluoroethylene propylene insulating layer 3 are jointly wrapped with a PTC layer 4, the PTC layer 4 is wrapped with a tear-resistant mixed braided layer 5, and the tear-resistant mixed braided layer 5 is wrapped with a The reinforcing sheath layer 6 is provided with a plurality of channels along the axial direction, and each channel is filled with a high-strength aramid yarn filling rope 7 .

[0045]The tear-resistant hybrid woven layer 5 is woven from carbon fiber and glass fiber.

[0046] The reinforcing sheath layer is composed of the following raw materials in parts by weight:

[0047] Trimethylolpropane 2-4, polyperf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com