Method for preparing barrier degradable composite plastic film

A plastic film and barrier technology, applied in the field of degradable plastic products, can solve the problems of plastic waste accumulation, environmental hazards, white pollution, etc., and achieve the effects of reduced degree of agglomeration, high degree of lipophilicity, and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

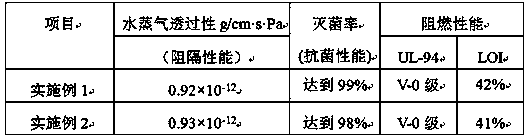

Embodiment 1

[0025] A method for preparing a barrier degradable composite plastic film, characterized in that it comprises the following steps, the following raw materials are by weight:

[0026] (1) Preparation of rare earth lanthanum-doped nano-titanium dioxide:

[0027] Add deionized water to 2 parts of modified nano-titanium dioxide at a mass ratio of 1:100, ultrasonically disperse for 1 hour, add 0.2 parts of lanthanum chloride, stir at 80°C for 2 hours, dry at 110°C for 4 hours, and then put in 700°C Calcined in a resistance furnace for 2 hours, and ground through a 200-mesh sieve to obtain rare earth lanthanum-doped nano-titanium dioxide;

[0028] Among them, the use of ultrasonic-microwave-assisted sodium laurate to modify nano-titanium dioxide: add 2 parts of nano-titanium dioxide and 0.003 parts of dispersant sodium hexametaphosphate to 67 parts of distilled water, adjust the pH to 5 with hydrochloric acid, add 0.3 parts of sodium laurate, and add 0.3 parts of sodium laurate. Af...

Embodiment 2

[0035] A method for preparing a barrier degradable composite plastic film, characterized in that it comprises the following steps, the following raw materials are by weight:

[0036] (1) Preparation of rare earth lanthanum-doped nano-titanium dioxide:

[0037] Add deionized water to 4 parts of modified nano-titanium dioxide at a mass ratio of 1:100, ultrasonically disperse for 2 hours, add 0.4 parts of lanthanum chloride, stir at 85°C for 1 hour, dry at 115°C for 3 hours, and then put it in 710°C Calcined in a resistance furnace for 1 hour, and ground through a 200-mesh sieve to obtain rare earth lanthanum-doped nano-titanium dioxide;

[0038] Among them, the use of ultrasonic-microwave-assisted sodium laurate to modify nano-titanium dioxide: add 4 parts of nano-titanium dioxide and 0.007 parts of dispersant sodium hexametaphosphate to 133 parts of distilled water, adjust the pH to 5 with hydrochloric acid, add 0.6 parts of sodium laurate, and add 0.6 parts of sodium laurate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com