Nanometer bismuth vanadate antifouling self-cleaning surface finishing aid for PVC

A surface finishing and self-cleaning technology, used in antifouling/underwater coatings, paints containing biocides, coatings, etc. High strength, strong adhesion and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

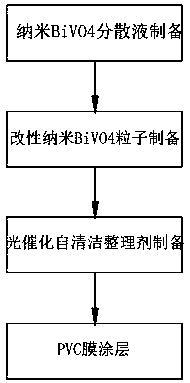

Method used

Image

Examples

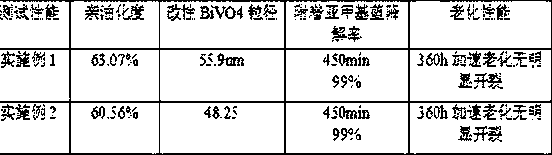

Embodiment 1

[0028] Example 1, adjust the pH of nano-BiVO4 particles, appropriate amount of absolute ethanol, NaOH and oxalic acid to 6, and use a high-speed emulsifier and ultrasonic instrument to disperse them for 10 minutes to prepare a 10% nano-BiVO4 dispersion.

[0029] Take an appropriate amount of nano-BiVO4 dispersion emulsion, add a certain amount of titanate coupling agent TM-P, adjust the pH to 6, reflux at 80°C for 2 hours, centrifuge the product, wash it to no ethanol, and dry it for 8 hours to obtain the modified BiVO4 particles.

[0030] Take an appropriate amount of modified BiVO4 particles, DMF, and 0.5% sodium hexametaphosphate, of which the content of modified BiVO4 particles is 5%, and use a high-speed emulsifier and an ultrasonic instrument to disperse them for 10 minutes, stir and react at 80 ° C for 2 hours, and obtain photocatalytic self-cleaning Finishing agent.

[0031] Use a coating machine to coat a 0.05 mm protective layer on the dry PVC film, pre-bake at 80°C...

Embodiment 2

[0032] Example 2, adjust the pH of nano-BiVO4 particles, appropriate amount of absolute ethanol, NaOH and oxalic acid to 6, and use a high-speed emulsifier and ultrasonic instrument to disperse them for 10 minutes to prepare a 12% nano-BiVO4 dispersion.

[0033] Take an appropriate amount of nano-BiVO4 dispersion emulsion, add a certain amount of titanate coupling agent TM-P, adjust the pH to 6, reflux at 80°C for 2 hours, centrifuge the product, wash it to no ethanol, and dry it for 10 hours to obtain the modified BiVO4 particles.

[0034] Take an appropriate amount of modified BiVO4 particles, DMF, and 0.5% sodium hexametaphosphate, of which the content of modified BiVO4 particles is 4%, disperse them with a high-speed emulsifier and an ultrasonic instrument for 10 minutes, stir and react at 80°C for 2 hours, and obtain photocatalytic self-cleaning Finishing agent.

[0035] Use a coating machine to coat a 0.05 mm protective layer on the dry PVC film, pre-bake at 80°C for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com