A kind of nano-modified transformer oil and preparation method thereof

A transformer oil and nano-modification technology, which is applied in the electric power field, can solve the problems of poor stability, short shelf life, and poor performance of transformer oil, and achieve high electrical insulation, reduce agglomeration, and improve electrical performance and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

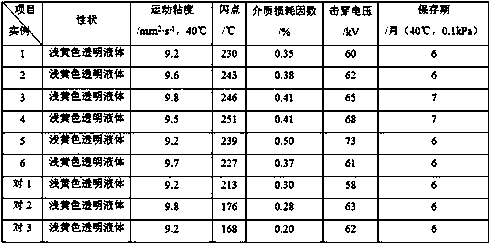

Examples

Embodiment 1

[0030] A nano-modified transformer oil, the transformer oil contains 0.15% by weight of modified aluminum nitride nanoparticles, and contains 0.2% by weight of modified α-Al 2 o 3 nanoparticles.

[0031] The preparation method of the modified aluminum nitride nanoparticles comprises the following steps:

[0032] (1) Put the aluminum nitride nanoparticles and silane coupling agent KH570 into the organic solvent absolute ethanol for 1 hour of ultrasonic oscillation, then add methyl methacrylate, react in a water bath at 60°C for 12 hours, and obtain a mixed solution, the aluminum nitride The weight ratio of nanoparticles to silane coupling agent and methyl methacrylate is 1:0.5:0.9;

[0033] The time of the ultrasonic oscillation is 10min, and the power is 800W;

[0034] The particle size of the aluminum nitride nanoparticles is 20 nm, and the density is 2.5 g / cm3 , the thermal conductivity is 150W / m·K;

[0035] (2) The mixed solution in step (1) was ball milled for 12 hours...

Embodiment 2

[0042] A nano-modified transformer oil, containing 0.35% by weight of modified aluminum nitride nanoparticles in the transformer oil, containing 0.5% by weight of modified α-Al 2 o 3 nanoparticles.

[0043] The preparation method of the modified aluminum nitride nanoparticles comprises the following steps:

[0044] (1) Put the aluminum nitride nanoparticles and silane coupling agent KH570 into the organic solvent diethyl ether for 1.5h ultrasonic oscillation, then add methyl methacrylate, react in a water bath at 60°C for 10h, and obtain a mixed solution, the aluminum nitride nano The weight ratio of particles to silane coupling agent and methyl methacrylate is 1:0.6:1.0;

[0045] The time of the ultrasonic oscillation is 5min, and the power is 1000W;

[0046] The particle size of the aluminum nitride nanoparticles is 30 nm, and the density is 2.73 g / cm 3 , the thermal conductivity is 180W / m·K;

[0047] (2) The mixed solution in step (1) was ball milled for 16 hours at a ...

Embodiment 3

[0054] A nano-modified transformer oil, containing 0.5% by weight of modified aluminum nitride nanoparticles in the transformer oil, containing 0.6% by weight of modified α-Al 2 o 3 nanoparticles.

[0055] The preparation method of the modified aluminum nitride nanoparticles comprises the following steps:

[0056] (1) Place aluminum nitride nanoparticles and silane coupling agent KH590 into the organic solvent isopropanol for 2 hours of ultrasonic vibration, then add methyl methacrylate, and react in a water bath at 70°C for 11 hours to obtain a mixed solution. The aluminum nitride The weight ratio of nanoparticles to silane coupling agent and methyl methacrylate is 1:0.7:1.1;

[0057] The time of the ultrasonic oscillation is 15min, and the power is 1200W;

[0058] The particle size of the aluminum nitride nanoparticles is 50 nm, and the density is 3.26 g / cm 3 , the thermal conductivity is 320W / m·K;

[0059] (2) The mixed solution in step (1) is ball milled for 20 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com