Lauric acid modified nano titanium dioxide as well as preparation method and application thereof

A technology of nano-titanium dioxide and titanium dioxide, applied in chemical instruments and methods, dyeing low-molecular organic compound treatment, inorganic pigment treatment, etc., can solve problems such as strong hydrophilicity, agglomeration, precipitation, etc., and achieve good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

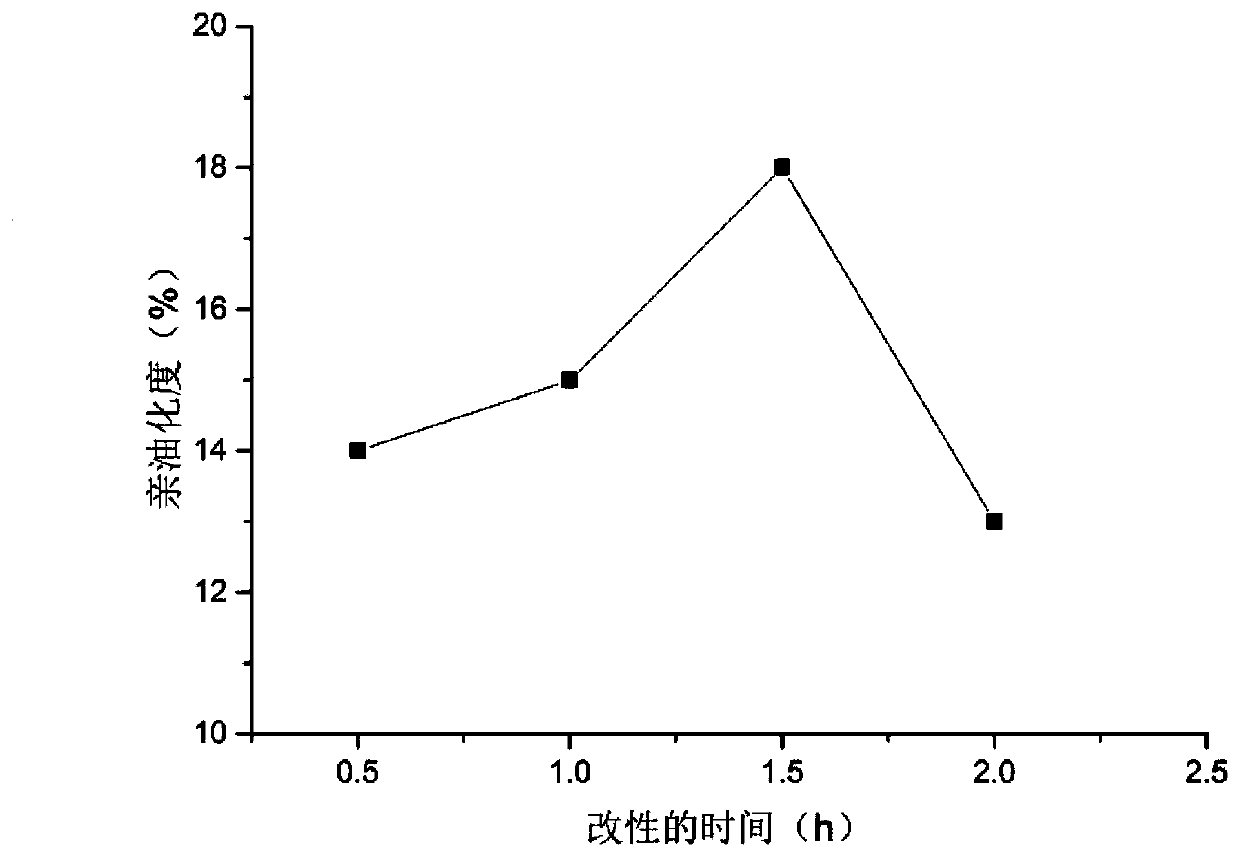

[0031] Surface modification of nano-titanium dioxide by hydrothermal method to prepare lauric acid-modified nano-titanium dioxide, the steps are: weigh 3g of titanium dioxide nanowires and 0.015g of sodium hexametaphosphate into a beaker, add an appropriate amount of deionized water, and put the beaker Put it on a magnetic stirrer for beating for 1 hour, then add dropwise sodium hydroxide to adjust the pH value of the slurry to 5, add 0.15g of lauric acid, put the beaker into a constant temperature heating magnetic stirrer, heat it in a constant temperature water bath at 85°C for 1.5 hours, and take it out. The obtained sample was left to age for half an hour, filtered with suction, and the obtained solid was reacted in an oven at 80°C for 24 hours to obtain the final product.

Embodiment 2

[0032] Embodiment 2 lipophilicity experiment

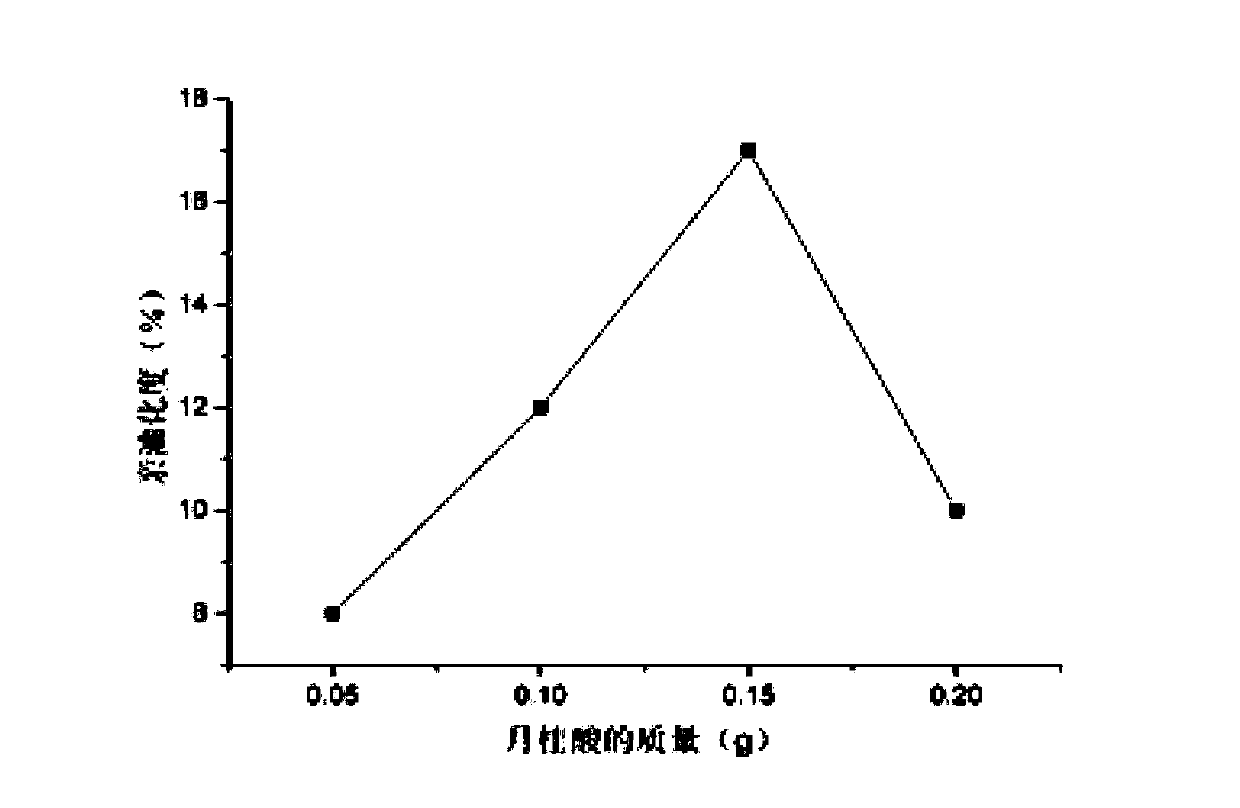

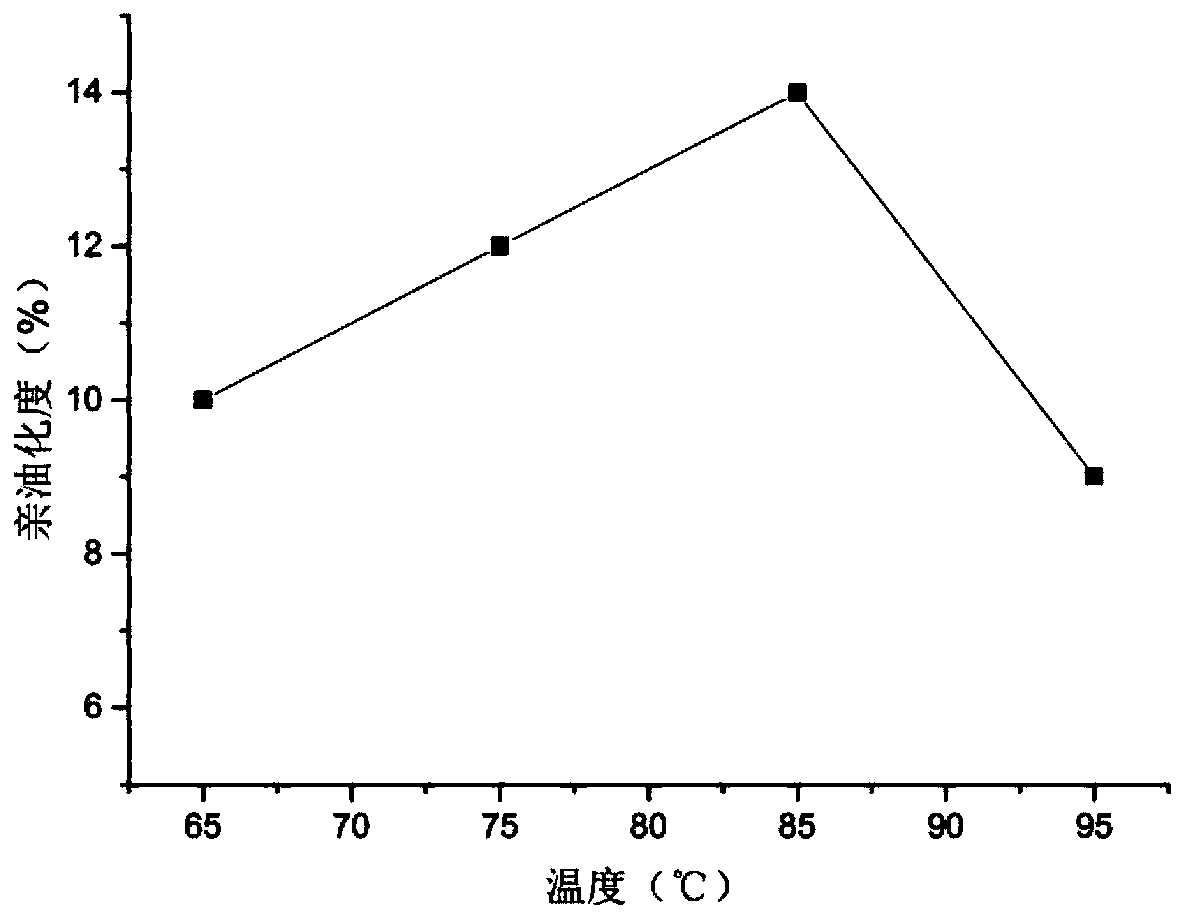

[0033] The modified nano-titanium dioxide sample prepared in Example 1 was ground and dried, and the modification effect was evaluated by measuring the degree of lipophilicity through a lipophilic degree experiment. At the same time, the amount of modifier lauric acid, the modification temperature, and the modified The influence of the curing time and the pH value of the solution on the modification effect.

[0034] Weigh about 1 g of modified titanium dioxide nanowires on an electronic balance, put them into a 50 mL beaker, and add 50 mL of distilled water. Then add methanol drop by drop, when the nano-titanium dioxide floating on the liquid surface is all wetted, record the amount V (mL) of the added methanol, and calculate the degree of lipophilicity by the formula Q=V / (50+V)× 100% results in the degree of lipophilicity of the sample, and the higher the degree of lipophilicity tested, the better the lipophilicity and hydrophob...

Embodiment 3

[0036] Embodiment 3 infrared spectrum experiment

[0037] The titanium dioxide nanowires before and after modification were detected by infrared spectroscopy to judge whether the nano-titanium dioxide was successfully modified by lauric acid. The results were as follows Figure 5 shown. It can be seen that the modified titanium dioxide nanowires are at 2923cm -1 and 2852cm -1 There is a new absorption peak at , which is mainly due to the stretching vibration of the methyl group. This new absorption peak is the non-polar part of the lauric acid on the surface of the modified nano-TiO2; the modified Nano-TiO2 due to The stretching vibration of C=O, at 1624cm -1 An absorption peak was generated at , indicating that the reaction between lauric acid and titanium dioxide nanowires was successful; due to the symmetric and asymmetric stretching vibrations of -COO, the modified nano-titanium dioxide was at 1463cm -1 and 1323cm -1 A new absorption peak was generated at , indicating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| burnout rate | aaaaa | aaaaa |

| burnout rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com