Preparation method of high-abrasion-resistant white carbon black for reinforcement of butadiene styrene rubber

A technology of styrene-butadiene rubber and white carbon black, which is applied in the direction of fibrous fillers, etc., can solve the problems of weak polymer binding force, poor compatibility, and reduced production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

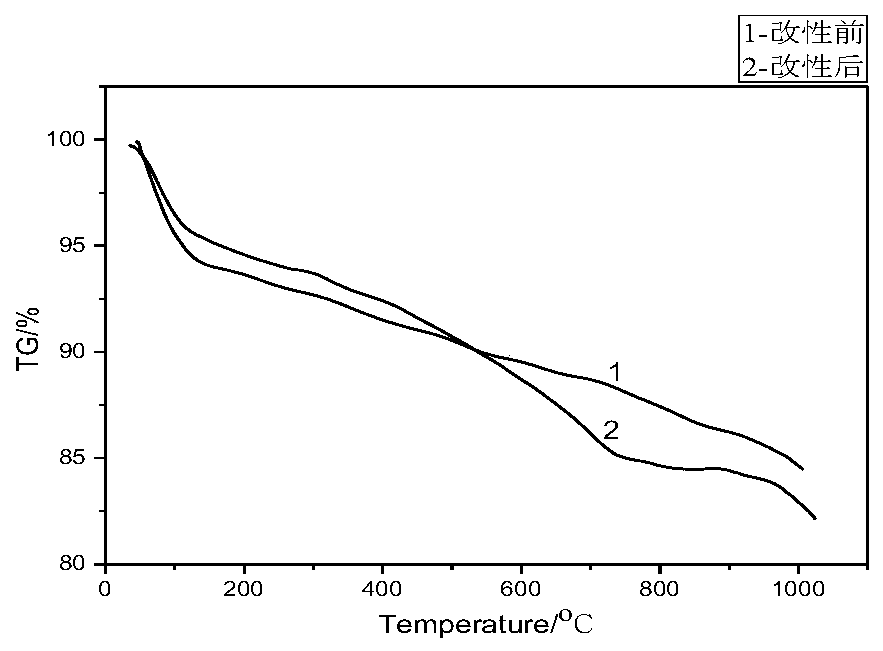

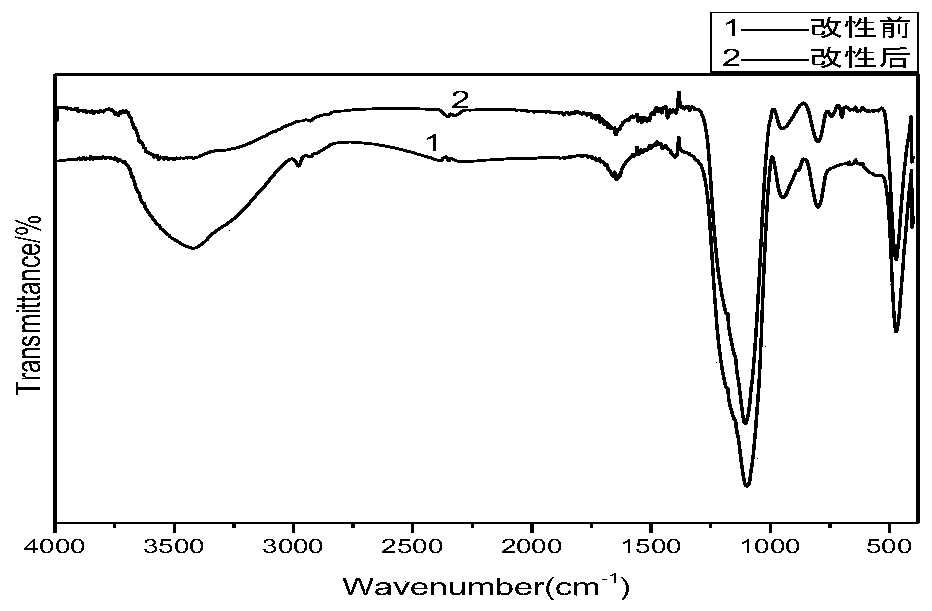

[0035] Add 400g of silica wet filter cake to a 2L reaction kettle, add 200g of deionized water, heat to 80°C with an oil bath, adjust the pH value of the solution to 3.5 with dilute sulfuric acid, and add the coupling agent phenyltrimethoxysilane 11.74g was subjected to modification reaction, and the modification time was 1.5h. Finally, it is washed with water, filtered by suction, and dried to obtain high wear-resistant white carbon black for reinforcing styrene-butadiene rubber.

Embodiment 2

[0037] Add 400g of silica wet filter cake to a 2L reaction kettle, add 200g of deionized water, heat to 80°C with an oil bath, adjust the pH value of the solution to 3.5 with dilute sulfuric acid, and add the coupling agent phenyltrimethoxysilane 19.57g was subjected to modification reaction, and the modification time was 1.5h. Finally, it is washed with water, filtered by suction, and dried to obtain high wear-resistant white carbon black for reinforcing styrene-butadiene rubber.

Embodiment 3

[0039] Add 400g of silica wet filter cake to a 2L reaction kettle, add 200g of deionized water, heat to 80°C with an oil bath, adjust the pH value of the solution to 3.5 with dilute sulfuric acid, and add the coupling agent phenyltrimethoxysilane 15.66g was subjected to modification reaction, and the modification time was 1.5h. Finally, it is washed with water, filtered by suction, and dried to obtain high wear-resistant white carbon black for reinforcing styrene-butadiene rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

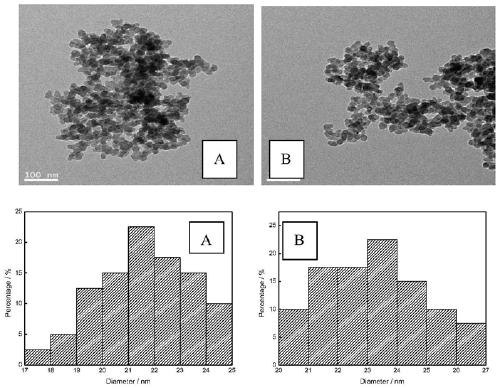

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com