Grinding method of rectangular electric connector

An electrical connector and grinding technology, which is applied in the direction of grinding workpiece supports, grinding machine parts, grinding/polishing equipment, etc. , Affect glass sealing performance and insulation performance, etc., to achieve the effect of improving product quality and production efficiency, reducing thermal stress, and ensuring sealing performance and insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

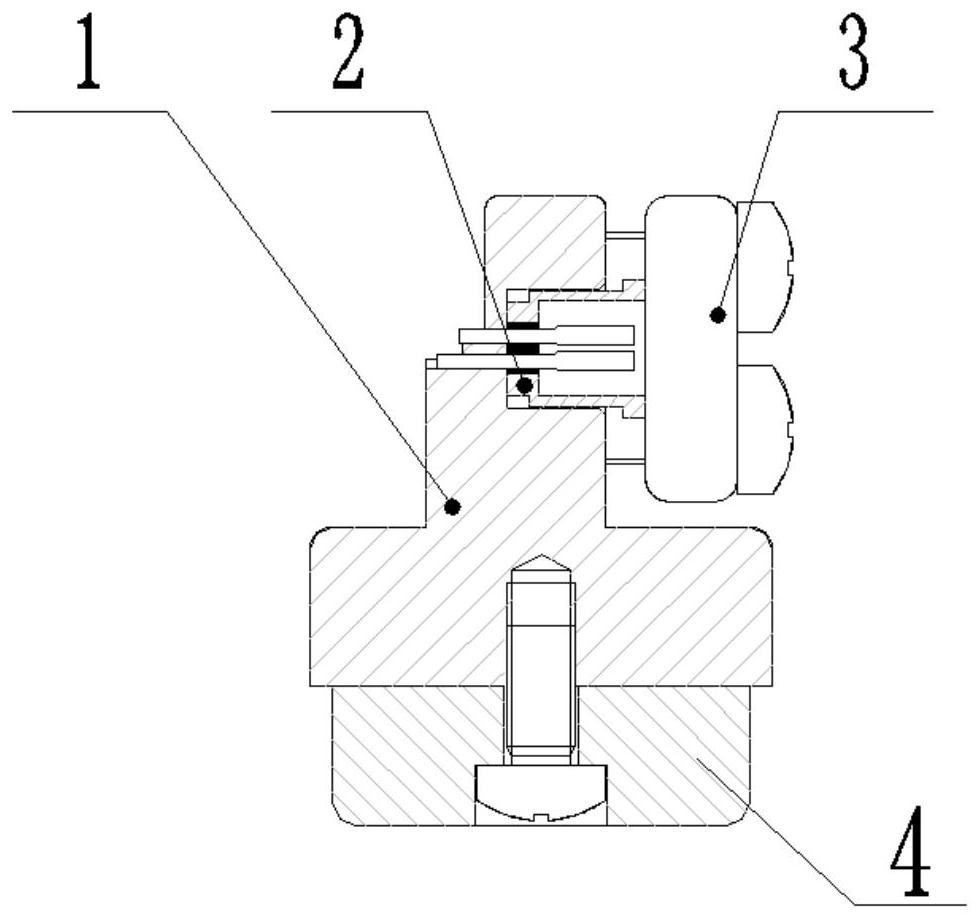

Image

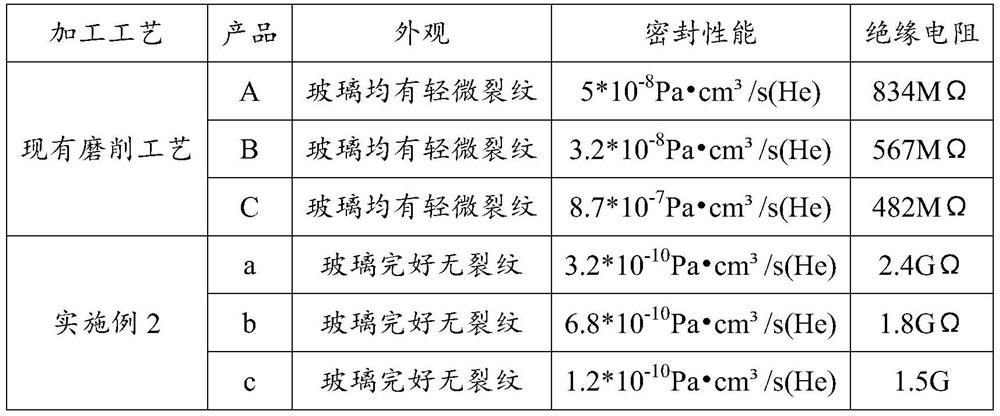

Examples

Embodiment 1

[0030] A grinding method for a rectangular electrical connector, comprising the steps of:

[0031] (1) After installing the 5000-mesh grinding wheel on the grinding machine, first repair the side of the grinding wheel, and then repair the end face of the grinding wheel to obtain the verticality;

[0032] (2) The special fixture should be placed flat and kept vertically downward to assemble the special fixture with the electrical connector, and then install the special fixture on the platform of the grinding machine; if the electrical connection cannot be assembled with the special fixture, it should be checked Whether the special fixture is blocked and whether the needle body of the electrical connector is bent; after the assembly is successful, you should also check whether the needle body of the electrical connector is flat. If the distance between the needle body and the end face of the fixture is inconsistent, the product is unqualified and cannot be processed this time;

...

Embodiment 2

[0039] A grinding method for a rectangular electrical connector, comprising the steps of:

[0040] (1) After installing the 5000-mesh grinding wheel on the grinding machine, first repair the side of the grinding wheel, and then repair the end face of the grinding wheel to obtain the verticality;

[0041] (2) The special fixture should be placed flat and kept vertically downward to assemble the special fixture with the electrical connector, and then install the special fixture on the platform of the grinding machine; if the electrical connection cannot be assembled with the special fixture, it should be checked Whether the special fixture is blocked and whether the needle body of the electrical connector is bent; after the assembly is successful, you should also check whether the needle body of the electrical connector is flat. If the distance between the needle body and the end face of the fixture is inconsistent, the product is unqualified and cannot be processed this time;

...

Embodiment 3

[0048] A grinding method for a rectangular electrical connector, comprising the steps of:

[0049] (1) After installing the 5000-mesh grinding wheel on the grinding machine, first repair the side of the grinding wheel, and then repair the end face of the grinding wheel to obtain the verticality;

[0050] (2) The special fixture should be placed flat and kept vertically downward to assemble the special fixture with the electrical connector, and then install the special fixture on the platform of the grinding machine; if the electrical connection cannot be assembled with the special fixture, it should be checked Whether the special fixture is blocked and whether the needle body of the electrical connector is bent; after the assembly is successful, you should also check whether the needle body of the electrical connector is flat. If the distance between the needle body and the end face of the fixture is inconsistent, the product is unqualified and cannot be processed this time;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com