Round-concave integrated wallpaper wall cloth printing and embossing production line

A printing embossing and production line technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of consumption, uneven embossing, easy physical plastic deformation, etc., to reduce quality problems, save glue, The effect of improving the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

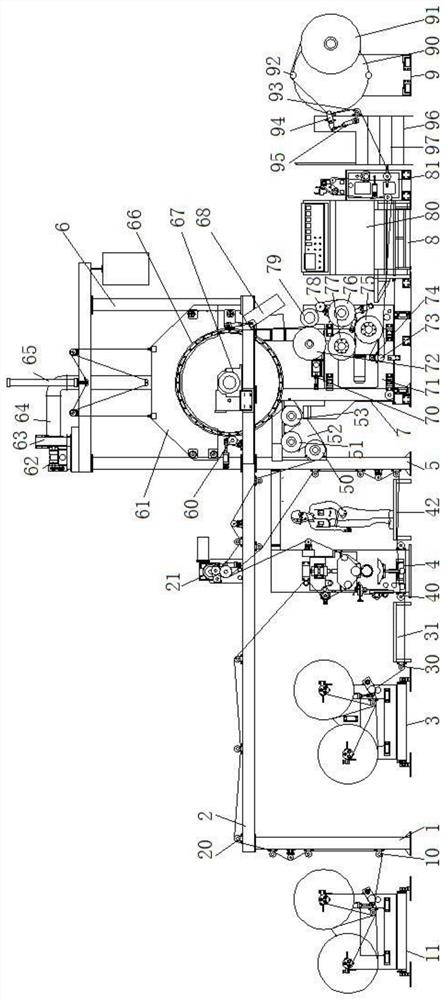

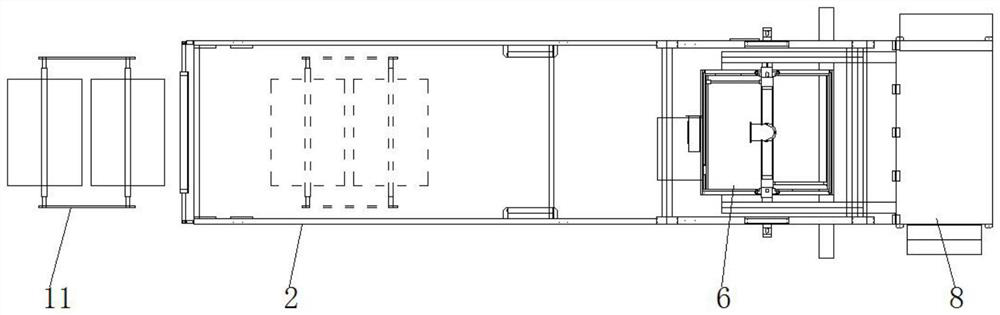

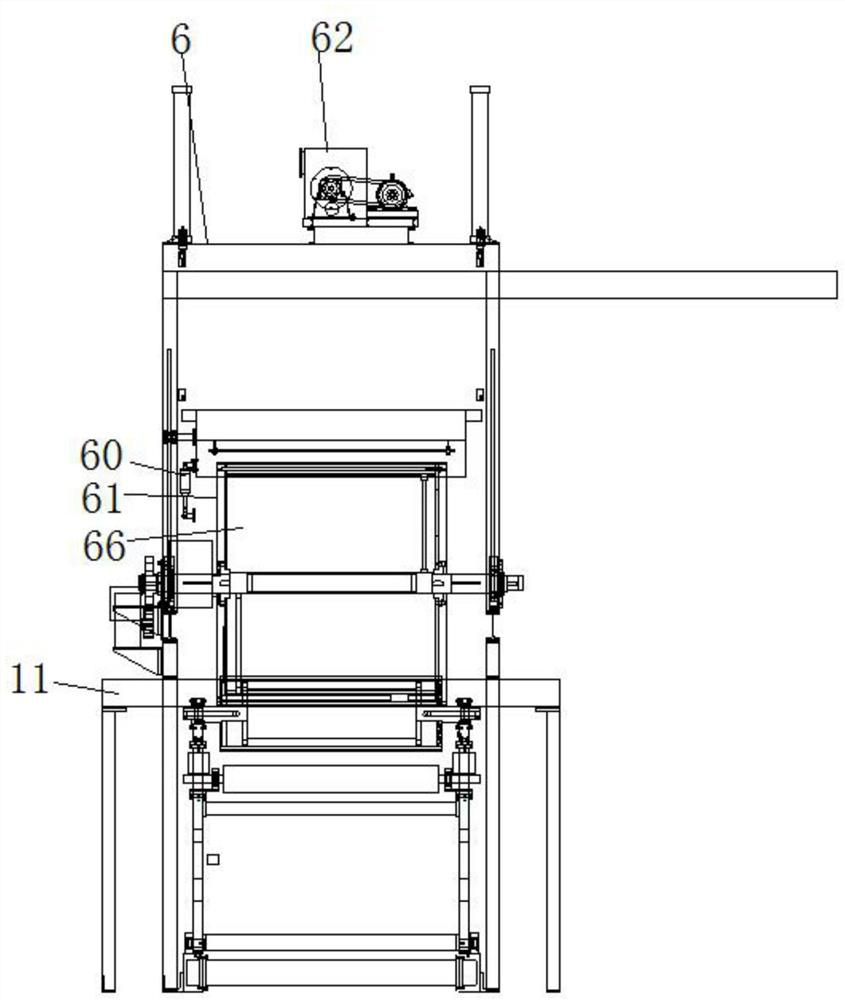

[0033] Specific implementation mode one, refer to Figure 1-7 , the present invention provides a technical solution: a circular concave integrated wallpaper wall covering printing and embossing production line, including a first support frame 1, a left top mounting frame 2, a gluing mechanism 4, a second support frame 5, and a right top mounting frame 6. The embossing mechanism 7 and the receiving mechanism 9, the upper ends of the first support frame 1 and the second support frame 5 are all supported on the lower end surface of the left top mounting frame 2, and the upper end surface of the left top mounting frame 2 is installed with multiple sets of first Two tension rollers 20 and a group of glue pressing mechanism 21, and the right top installation frame 6 is installed between the second support frame 5 and the upper end of the embossing mechanism 7, and the right side of the embossing mechanism 7 is provided with a console Mechanism 8, an electric control cabinet 80 is in...

specific Embodiment approach 2

[0035] Specific embodiment two, this embodiment is a further limitation to specific embodiment one, in the present invention, the material of the wall panel of the discharge rack on the PVC discharge mechanism 11 is high-strength cast iron, which is paired and processed by precision machinery, so it is more durable Firm, double-station unloading rack at the same time, manual refilling without stopping, effectively improving unloading efficiency, and unloading is stable.

specific Embodiment approach 3

[0036] Specific embodiment three, this embodiment is a further limitation to specific embodiment one, in the present invention, the structures of PVC discharging mechanism 11 and cloth base discharging mechanism 3 are set identically, and PVC discharging mechanism 11 is used for unwinding PVC material, and The cloth base unwinding mechanism 3 is used for unwinding the cloth base material, and the speed and direction are conveniently set synchronously, so that the double materials are stably glued together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com