Air-blowing type labeling device

An air blowing and air distribution technology, applied in labeling machines, labels, packaging, etc., can solve the problems of return time, secondary pollution, slow speed, etc., achieve uniform air pressure distribution, prevent secondary pollution, and reduce pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

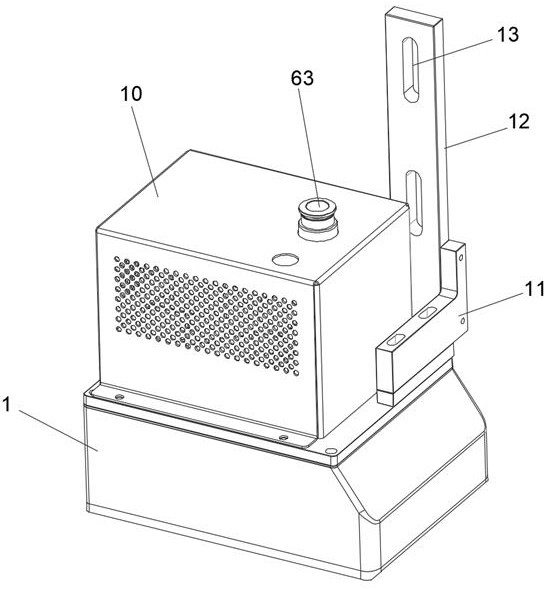

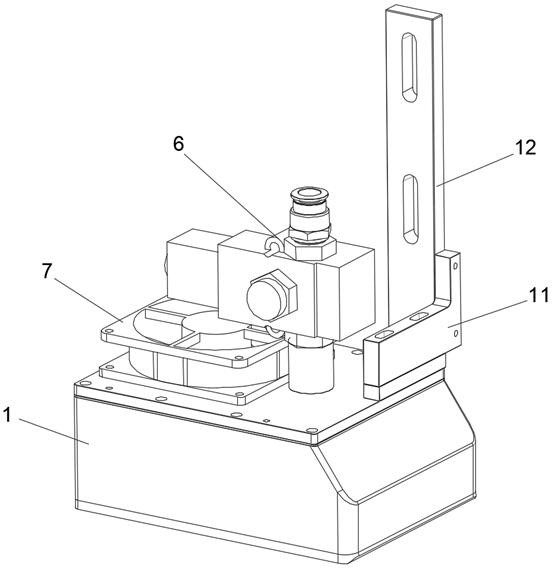

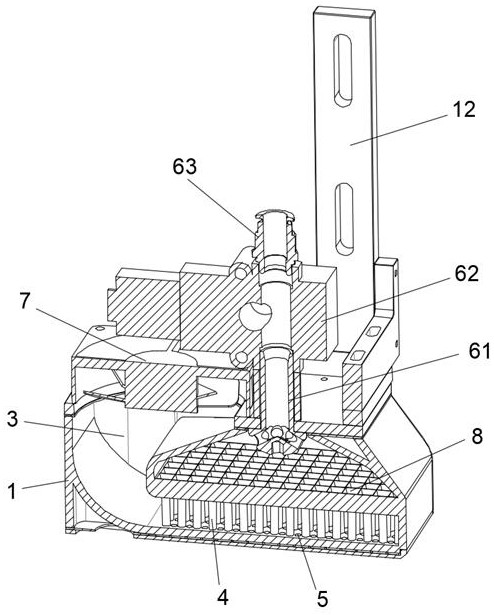

[0032] Embodiment one, such as Figure 1-5 As shown, an air-blowing labeling device includes an air distribution box 1, an air blowing chamber 2 and an air suction chamber 3 are arranged inside the air distribution box 1, and several air pipes 4 are fixedly installed on the lower surface of the air blowing chamber 2 , the trachea 4 is fixedly installed on the lower surface of the suction chamber 3, the lower surface of the suction chamber 3 is provided with some suction holes 5, the suction chamber 3 communicates with the outside through the suction holes 5, and the blowing chamber 2 Communicate with the outside through the trachea 4;

[0033] Air intake device 6 and fan 7 are fixedly installed on the upper surface of air distribution box 1, and air intake device 6 comprises air intake core 61, air intake control valve 62 and intake pipe 63, and one end of air intake core 61 passes through air distribution box 1 and Fixedly communicated in the blowing chamber 2, the other end...

Embodiment 2

[0036] Embodiment 2, as a further preferred solution of Embodiment 1, the air blowing chamber 2 is an inverted funnel structure, and the lower surface of the air blowing chamber 2 is provided with a number of air outlets 8, and each air outlet 8 corresponds to a trachea 4 respectively, and the outlet The air hole 8 has a funnel-like structure, and the small mouth end of the air outlet hole 8 communicates with the upper end of the trachea 4 ; the large mouth end of the air outlet hole 8 is located in the blowing chamber 2 . By designing the air blowing chamber 2 as an inverted funnel structure, it can not only reduce the air intake required for the space of the air blowing chamber 2, but also ensure that the air pressure in the air blowing chamber 2 is concentrated downward, thereby ensuring the protection of the label. Blowing effect. And by setting all the air outlet holes 8 as a funnel-like structure, it can further ensure that the air pressure in the blowing chamber 2 can b...

Embodiment 3

[0037] Embodiment 3, as a further preferred solution of Embodiment 2, the lower end of the air intake core 61 is a mushroom-like structure, and the end of the air intake core 61 is provided with a number of air intake holes 64, and the air intake holes 64 are arranged in a circular shape. The lower end of the air intake core 61 , and the sum of the areas of the air intake holes 64 is greater than or equal to the inner diameter area of the straight pipe portion of the air intake core 61 . Through the mushroom-shaped air intake core 61, the intake air can be dispersed and quickly filled with the blowing chamber 2, thereby reducing the pressure loss, so as to further ensure that the air pressure in the blowing chamber 2 is evenly distributed, forming a uniform blowing of the entire surface, and finally ensuring Each air pipe 4 has air blowing and the air pressure is consistent, so as to ensure that the labeling effect is smooth. And in this embodiment, the sum of the areas of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com