Phase state separation device and phase state separation method

A technology of phase separation and separation method, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve secondary pollution, inconvenience, incomplete problem solving, etc. problem, to achieve the effect of easy compression and good separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

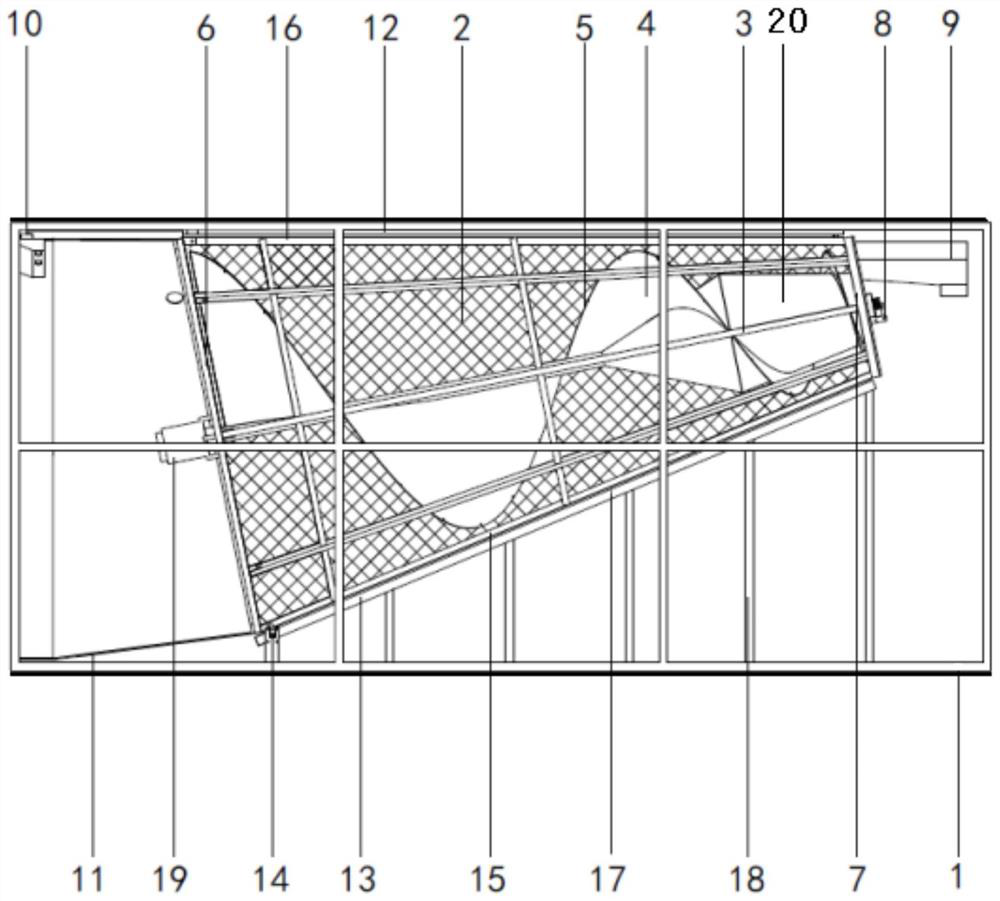

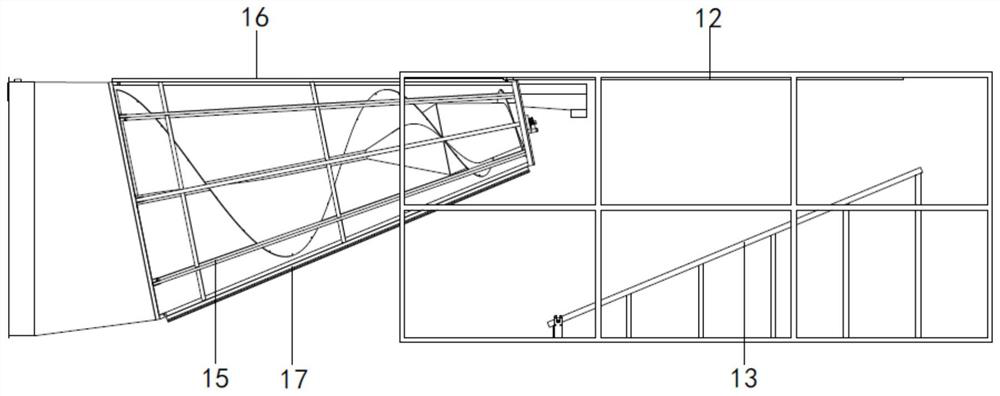

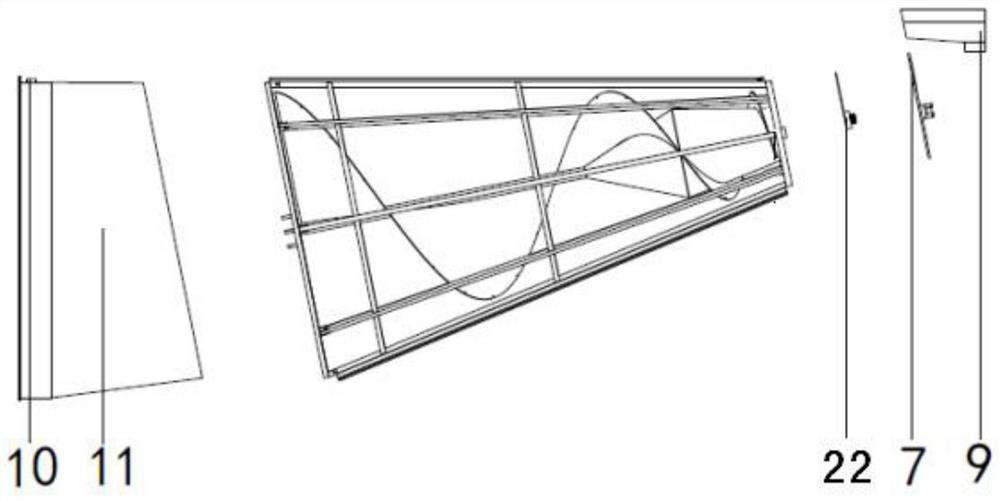

[0037] Refer to attached Figures 1 to 3 As shown, the phase separation device of this embodiment includes an outer cylinder body 1, a support mechanism disposed inside the outer cylinder body 1, and an actuator supported and fixed by the support mechanism. The outer cylinder body 1 is a cylinder structure with both ends open, and is used to fix the actuator inside it through the support mechanism to form a phase state processing device with a regular appearance. One end of the outer cylinder body 1 is the water inlet end, the direction of the water inlet end is preferably opposite to the flow direction of the substrate, and the other end is the water outlet end. The actuator is used to realize the separation of substances in different phases and substances in the same phase, and its specific examples are as follows.

[0038] In this embodiment, the actuator includes a cylindrical filter 2 and a screw mechanism arranged inside the cylindrical filter 2 . The front end of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com