Superfine fiber production equipment based on principle of composite spinning method

A technology for ultra-fine fibers and production equipment, which is applied in the directions of stretch spinning, filament generation, textiles and papermaking, and can solve the problems of time-consuming, labor-intensive and low-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

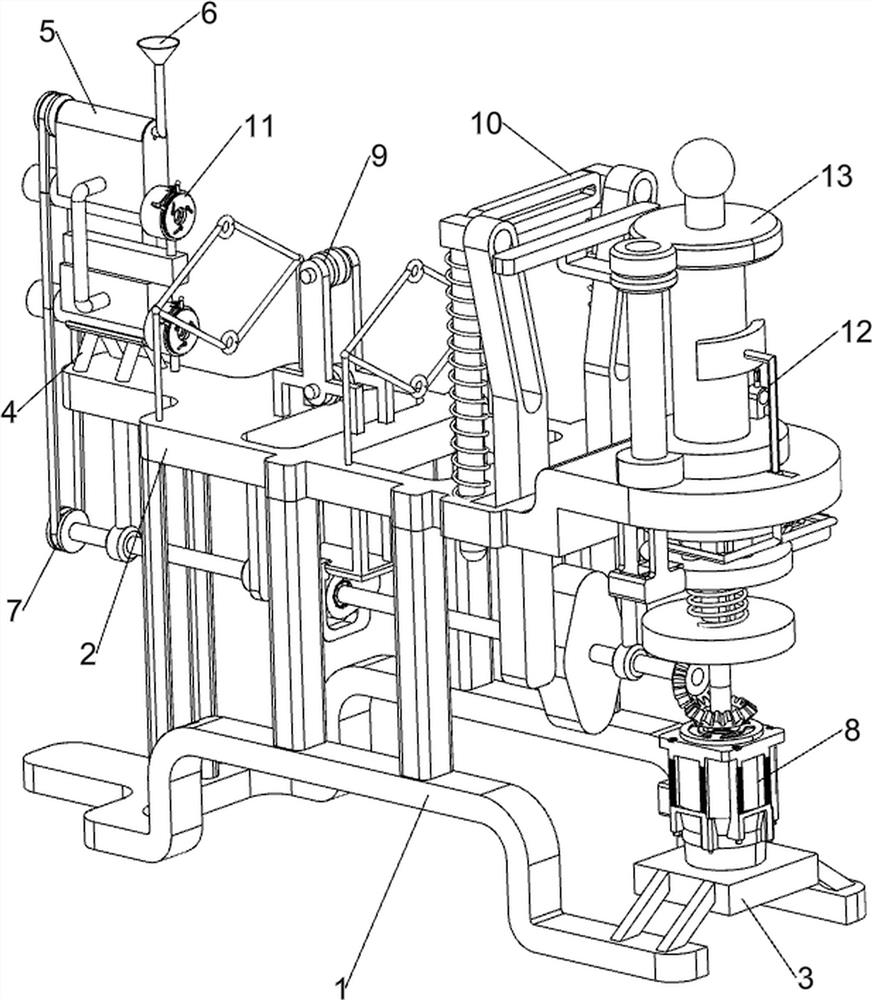

[0057] A kind of superfine fiber production equipment based on the principle of composite spinning method, such as figure 1 As shown, it includes a bottom frame 1, a placement plate 2, a motor support plate 3, a first fixed frame 4, a liquid passing frame 5, a lower liquid funnel 6, a blanking assembly 7, a winding assembly 8 and an extension assembly 9, and the bottom frame 1 The top is provided with a placement plate 2, and the rear side of the top of the placement plate 2 is provided with a first fixing frame 4. Two liquid passing frames 5 are connected to the first fixing frame 4. The liquid passing frames 5 are arranged up and down, and the upper side of the liquid passing frame 5 A lowering funnel 6 is provided on the front side of the top, and the bottom of the placement plate 2 is connected with a blanking assembly 7 for intermittent feeding of chemicals, and a stretching device for stretching the fibers is connected between the blanking assembly 7 and the placement pla...

Embodiment 2

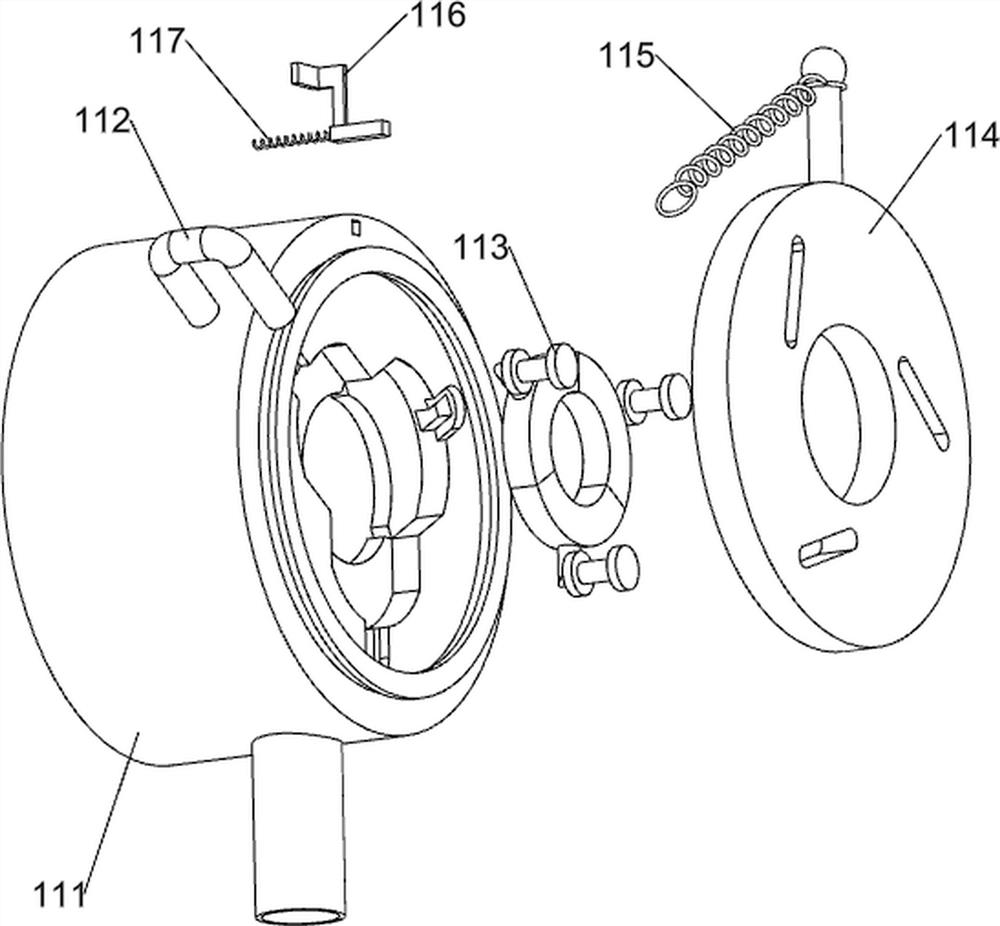

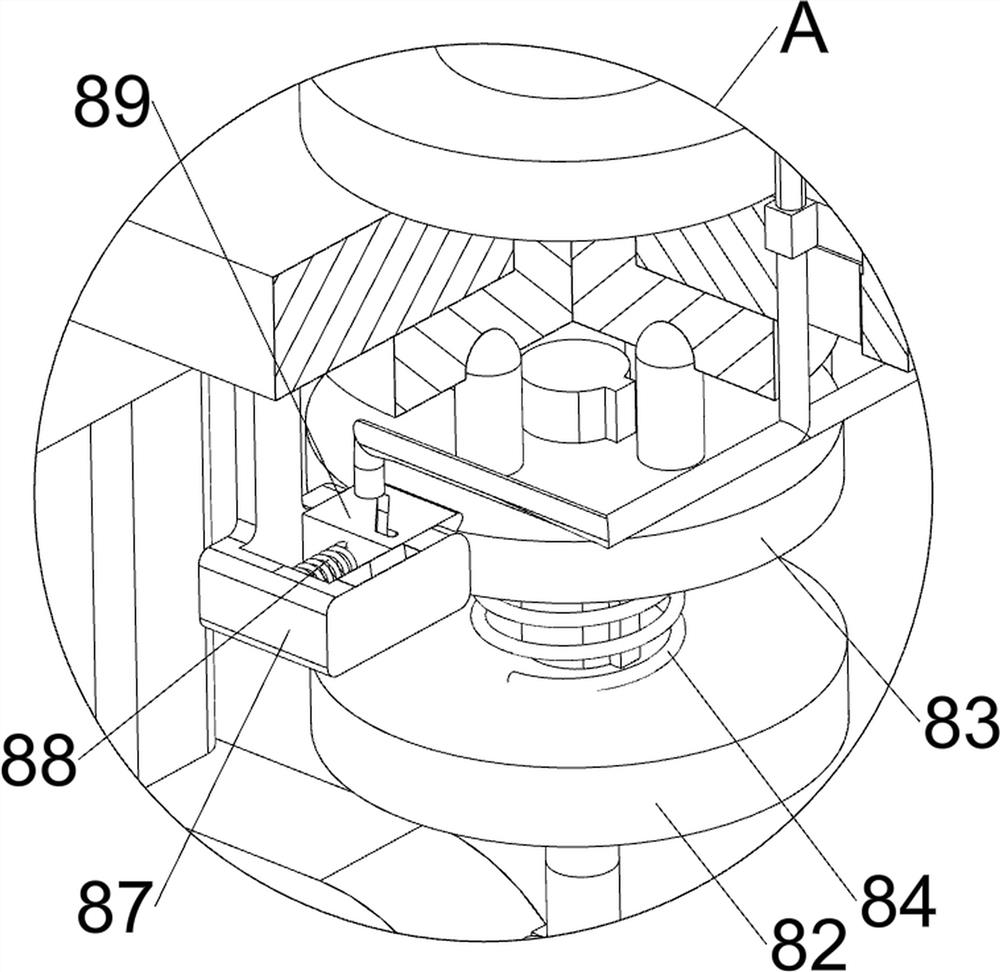

[0060] On the basis of Example 1, such as Figure 2 to Figure 6 As shown, the winding assembly 8 includes a servo motor 81, a first turntable 82, a chuck 83, a first spring 84, a rotating frame 85, a first sliding frame 86, a first limit frame 87, a second spring 88 and a wedge block 89, the top of the motor support plate 3 is provided with a servo motor 81, the output shaft of the servo motor 81 is connected with a first turntable 82, and the top of the first turntable 82 is slidably provided with a chuck 83, between the chuck 83 and the top of the first turntable 82 The first spring 84 is connected between them, the rotating frame 85 is placed on the front part of the placing plate 2, and the bottom of the rotating frame 85 cooperates with the chuck 83. The front side is symmetrically provided with a first spacer 87, and the first spacer 87 is slidably provided with a wedge 89. The left and right ends of the first slide 86 are slidably connected with the same side wedge 89. ...

Embodiment 3

[0065] On the basis of Example 2, such as Figure 7 and Figure 8 As shown, a lifting assembly 10 is also included, and the lifting assembly 10 includes a second cam 101, a second sliding frame 102, a second thread passing frame 103 and a third spring 104, and the front part of the rotating shaft 72 is provided with a second cam 101, placed The front part of the board 2 is slidingly provided with two second sliding frames 102. The second sliding frames 102 are arranged symmetrically on the left and right. The second sliding frames 102 are matched with the second cam 101. frame 103 , the second thread passing frame 103 is slidably connected to the upper part of the second sliding frame 102 , and two third springs 104 are connected between the second thread passing frame 103 and the top of the placing plate 2 .

[0066] The staff can pass the two fibers through the lower part of the liquid passing frame 5 on the same side, pass through the corresponding first thread passing fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com