Flange position degree testing fixture

A position degree and flange technology, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of inability to detect the position degree of flange holes, reduce detection costs, improve detection efficiency, and make production and operation simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples.

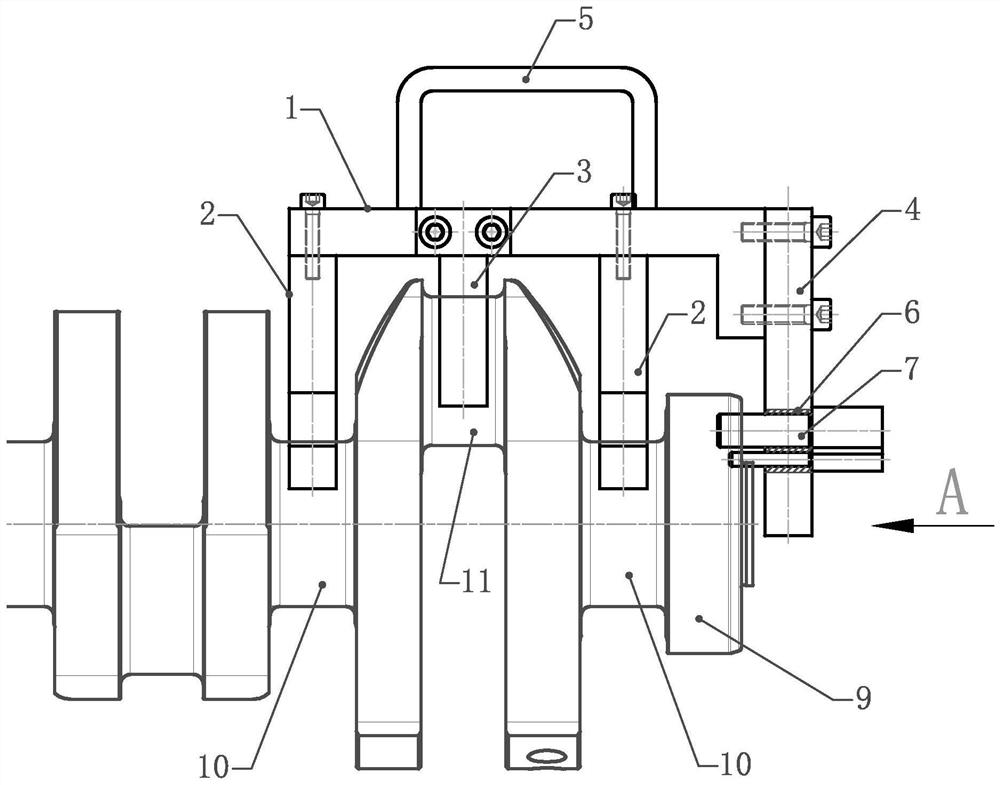

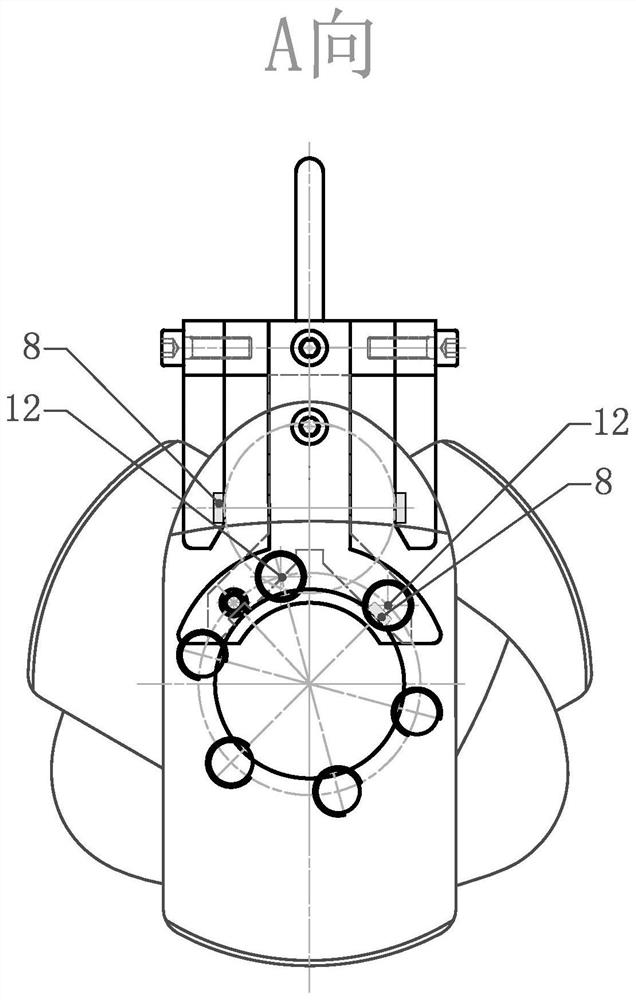

[0026] like figure 2 , image 3 As shown, a flange position inspection tool is provided with a inspection body 1, the lower end of the inspection body 1 is connected to two main shafts V-shaped 2, and a gasket 8 is welded on the main shaft V-shaped 2, and the material of the gasket is a cemented carbide block , For example: ZK20, YW2, etc., the liner 8 and the main journal 10 on the crankshaft 9 are closely positioned to determine the centerline of the main shaft.

[0027] Check the concrete 1 and connect two connecting rod neck positioning blocks 3 on the front and rear sides respectively. The connecting rod neck positioning blocks 3 are respectively welded with gaskets 8, and the gaskets 8 and the connecting rod journal 11 on the crankshaft 9 are closely positioned to determine Connecting rod centerline.

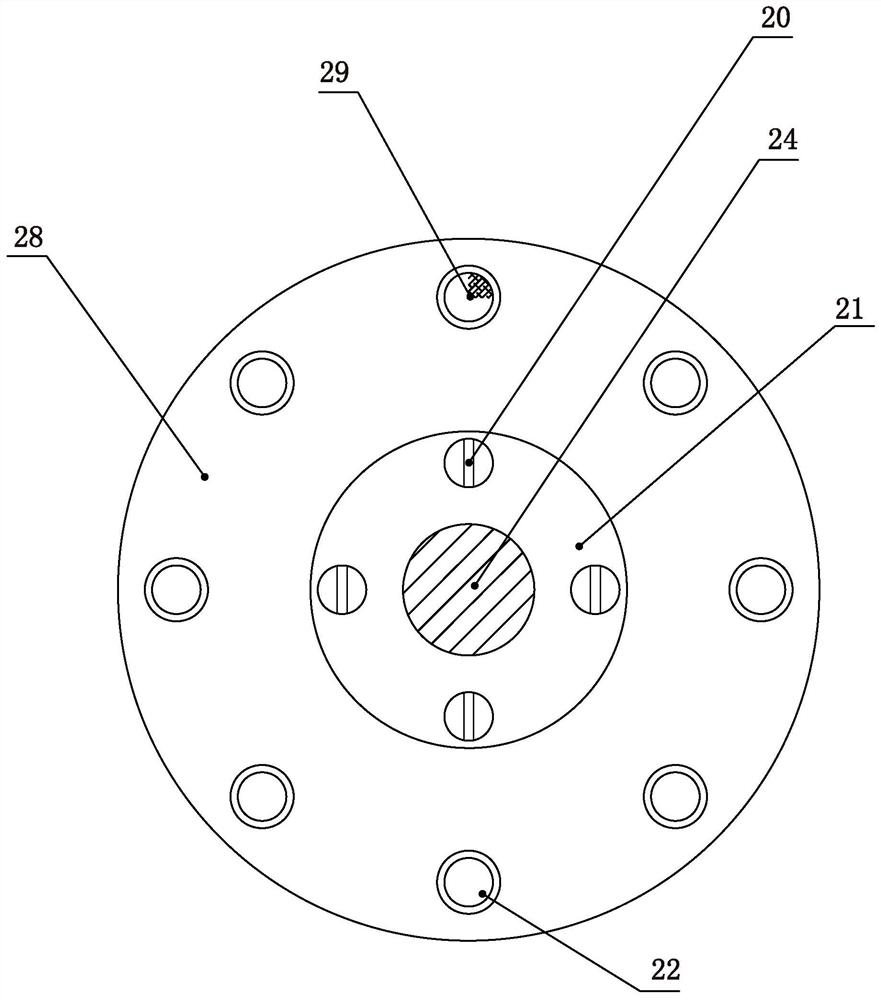

[0028] The right side of the inspection body 1 is connected to the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com