Fuel rail damper with locating features

A damper and fuel rail technology, applied in special fuel injection devices, low-pressure fuel injection, low-pressure fuel injection, etc., can solve problems such as loss, displacement, and increased noise of tail-end retainers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

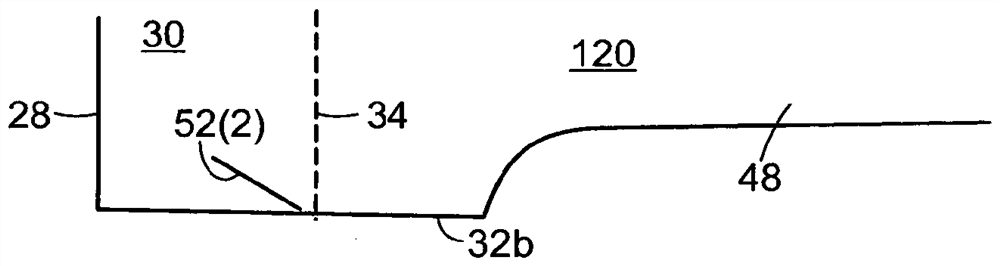

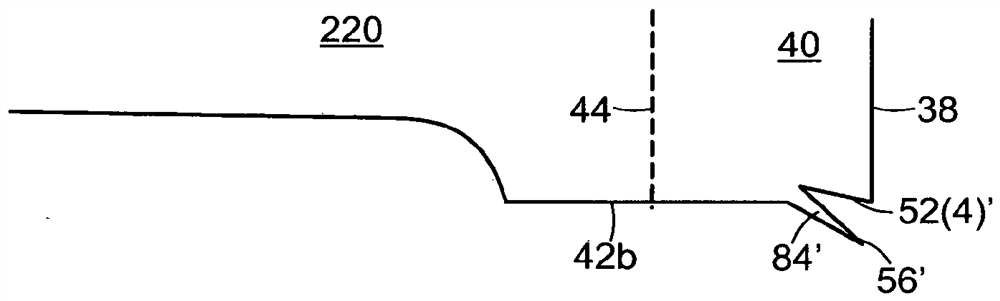

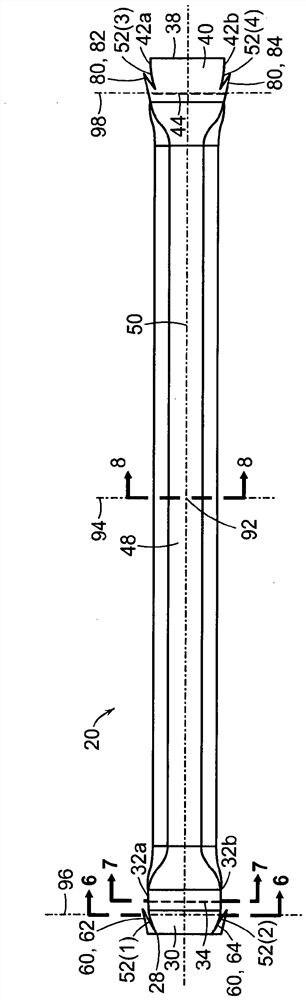

[0048] see figure 1 -3, the fuel system 1 is used to deliver fuel to the engine (not shown) of the vehicle. The fuel system 1 includes a fuel rail 2 , a damper 20 provided inside the fuel rail 2 , and a fuel injector 10 coupled to the fuel rail 2 . The fuel rail 2 is an elongated rectangular hollow tube comprising walls 4 defining fuel passages 6 . The fuel rail 2 includes fuel outlets 8 formed in a wall receiving the fuel injectors 10 . A fuel outlet 8 supplies fuel, such as gasoline or diesel, to the engine from a fuel passage 6 through a fuel injector 10 . Although three fuel outlets 8 and three fuel injectors 10 are illustrated, the fuel rail may include a greater or lesser number of fuel outlets 8 and fuel injectors 10 and the provided fuel outlets 8 and fuel injectors 10 The number corresponds to the number of fuel injectors and intake ports of the engine. The damper 20 is positioned and retained within the fuel rail 2 via retainers 60 , 80 provided on each end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com