Novel double-station double-glue-valve dispensing and hot-pressing preparation process for traceless underwear

A preparation process and double-station technology, applied in corsets, clothing, applications, etc., can solve the problems affecting product quality and production efficiency, mainly manual work, and many labors, so as to reduce the dependence on technical level and proficiency, The effect of ensuring quality and production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

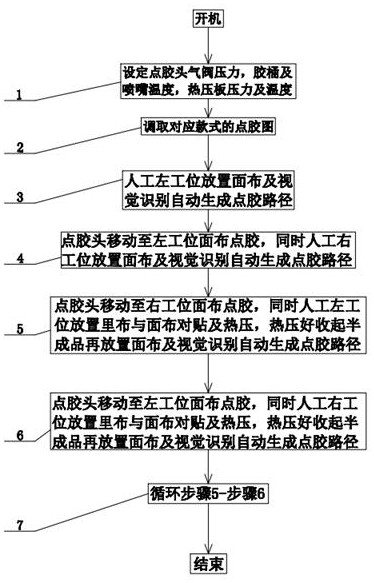

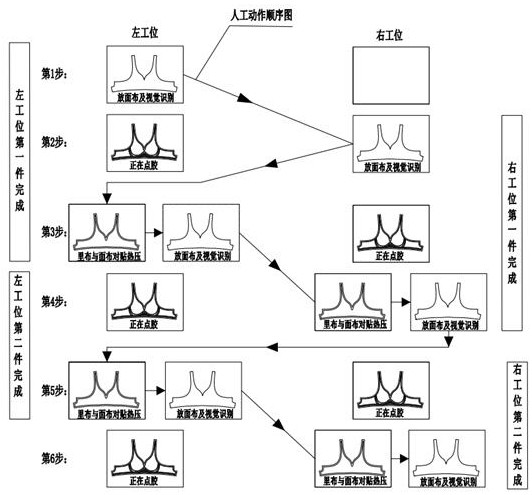

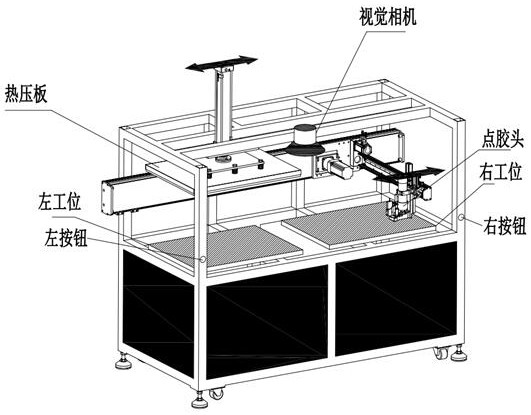

[0030] see Figure 1-Figure 3 As shown, the technical solution adopted in this embodiment is: it specifically includes the following steps:

[0031] Step 1. Set the air pressure valve pressure of the machine dispensing head, the temperature of the machine glue barrel and the temperature of the nozzle according to the requirements of the process parameters; set the pressure of the air pressure valve of the machine hot pressure plate and the temperature of the hot pressure plate; the pressure of the air pressure valve of the dispensing head is 6.5±0.5 bar, the temperature of the glue barrel is 100-140°C, the temperature of the nozzle is 200-240°C, the specific temperature is adjusted according to the glue of different manufacturers; the pressure of the air pressure valve of the hot pressure plate is 1-3bar, and the temperature of the hot pressure plate is 60-80°C The pressure and temperature are adjusted according to different fabrics; after setting the parameters, select the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com