A drain valve that is easy to clean and its application method

A technology of traps and cleaners, applied in separation methods, chemical instruments and methods, steam traps, etc., can solve the problems of filter blockage, time-consuming and labor-intensive cleaning, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

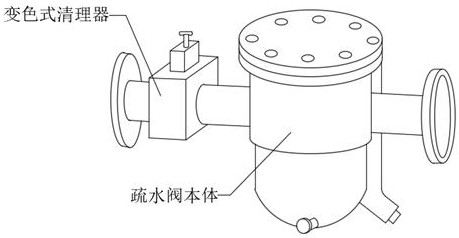

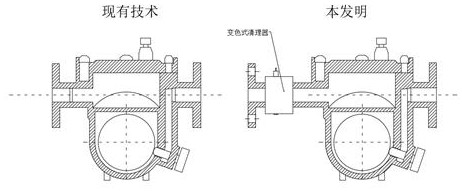

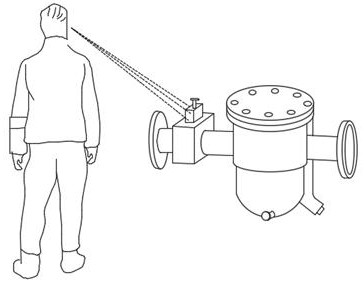

[0049] see Figure 1-10 , an easy-to-clean steam trap, including the trap body, and a color-changing cleaner connected to the water inlet pipe of the trap, see figure 1 , 2 The color-changing cleaner includes a connecting seat 1, the inner wall of the lower end of the connecting seat 1 is provided with a settling tank 101, and the inner wall of the lower end of the connecting seat 1 on one side of the settling tank 101 is fixedly connected with a filter 2, and the settling tank 101 is next to the filter 2 is set in order to allow impurities to sink smoothly into the settling tank 101, and the depth of the settling tank 101 is greater than the moving distance of the centrifugal cleaning bowl 6. The color chip 9 is indented into the connecting seat 1, the lower end of the settling tank 101 is threadedly connected with a discharge valve 3, the outer wall of the upper end of the connecting seat 1 is fixedly connected with a transparent color viewing shell 4, and the color viewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com