Biomacromolecular drug synthesis device

A technology for the synthesis of biological macromolecules and drugs, which is applied in the fields of feeding devices, chemical/physical/physical-chemical processes, detailed information of chemical/physical/physical-chemical reactors, etc. Influence, inability to get drugs and other problems, to achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

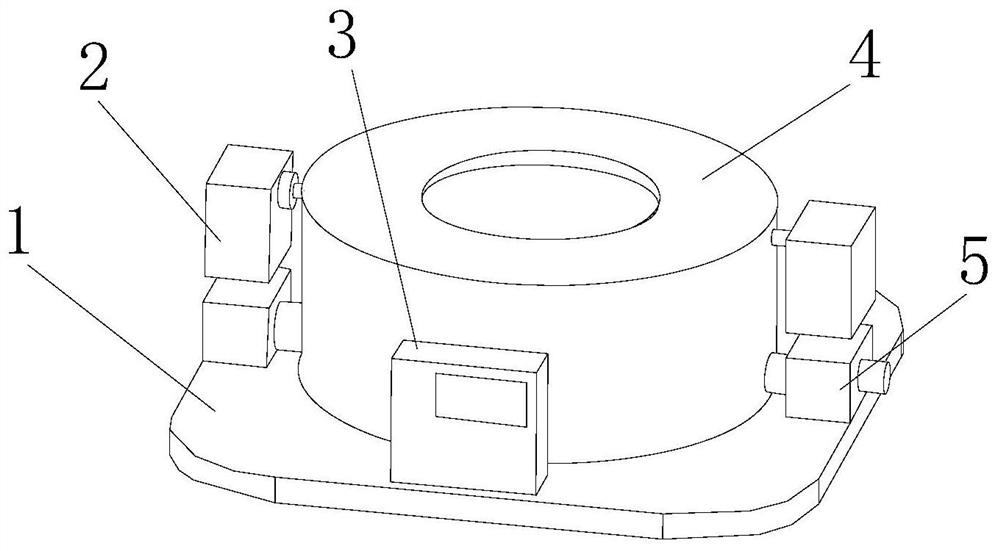

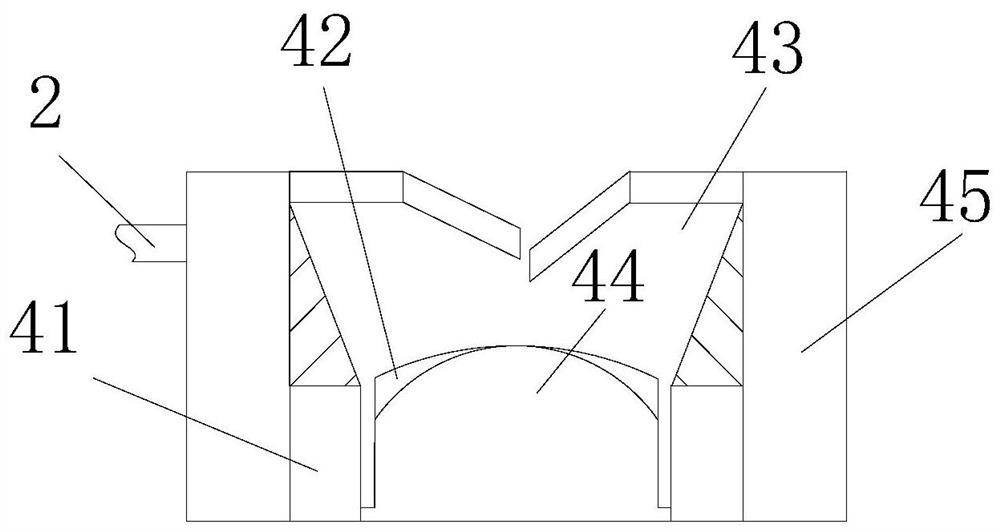

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a biomacromolecule drug synthesis device, the structure of which includes a base 1, a motor 2, an operation panel 3, a reaction kettle 4, and a driving machine 5. The reaction kettle 4 is installed on the base 1, and the The reaction kettle 4 cooperates with the operation panel 3 through the motor 2 and the driving machine 5 in an electrically connected manner. The reaction kettle 4 includes an inner groove 41, a slip ring 42, an auxiliary inlet 43, a powder basin 44, and a kettle body 45. The inner ditch 41 is welded and connected in the kettle body 45, and a powder basin 44 is fixedly connected therebetween through a slip ring 42. The powder basin 44 is provided with an auxiliary inlet 43, and the auxiliary inlet 43 includes a landslide 431 and a switch plate 432. , a jacking piece 433, a material guide plate 434, a lower limit device 435, a dispersion chamber 436, the landslide 431 is welded and conn...

Embodiment 2

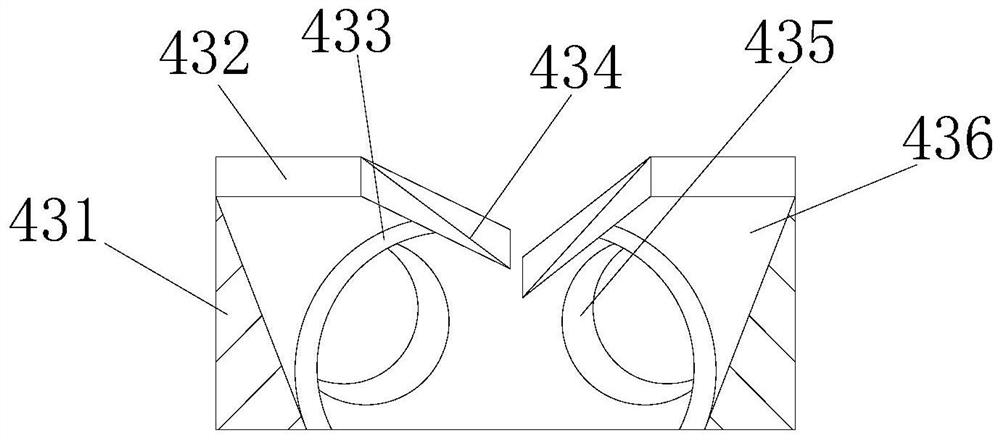

[0029] Such as Figure 4-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The top joint 433 includes a flashing plate 331, a marble 332, a contact bag 333, a guide clip 334, an inner limit groove 335, a roller The shaft 336, the contact bag 333 is fixedly connected to the inserting plate 331, and is welded to the guide clip 334, the inner side of the guide clip 334 is provided with an inner limit groove 335, and the inner limit groove 335 is rolled and fitted with a roller 336, the ball 332 is installed in the touch bag 333, and the insert plate 331 is provided with two, which are engaged on the material guide plate 434 and the landslide 431 through the touch bag 333, and will be affected by the lower limit device 435. Inclination angle, the lower limit device 435 includes an arc plate 351, a running-in belt 352, an adjustment structure 353, a top handle 354, a telescopic paddle 355, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com