Residual film bundling and recycling machine

A technology of recycling machine and residual film, applied in the field of agricultural machinery, can solve the problems of high labor intensity, high frequency of loading and unloading shutdown, and inability to bundle residual film, so as to improve work quality and efficiency, large tension and rotation space, and reduce soil entry. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] With reference to the accompanying drawings, the structure of specific embodiments of the present invention is described in detail as follows:

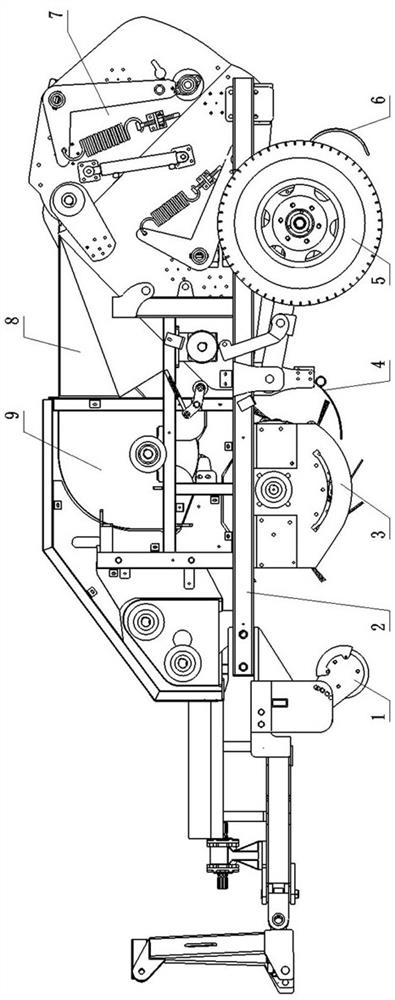

[0076] A residual film bundling recovery machine, comprising a main frame 2, a traveling wheel 5, a fan 9 arranged on the main frame 2, an air delivery channel 8, a depth-limiting roller 1, and a film holding tooth 6, and also includes a main frame 2 The segmented pick-up roller combination device and the residual film recycling automatic bundling device 7;

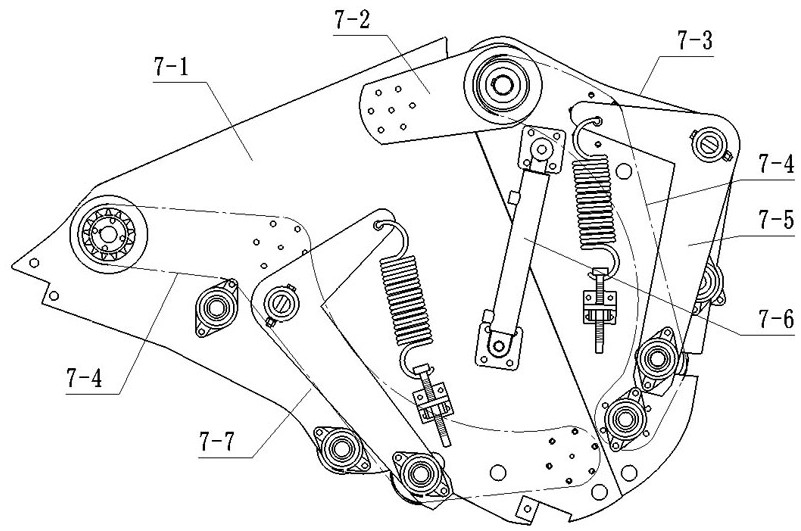

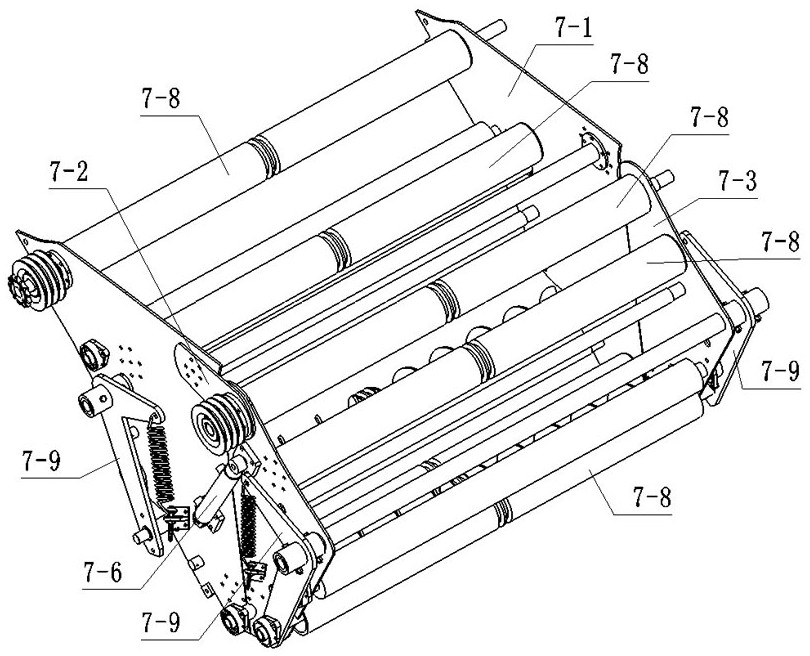

[0077] The automatic bundling device 7 for residual film recovery mainly includes two half-shells of the chassis that are fastened together, namely the half-shell of the chassis I7-1, the half-shell of the chassis II7-3, and the half-shell of the chassis I7- 1 is connected to the main frame, the upper part of the half-shell II7-3 of the chassis is hinged to the upper part of the half-shell I7-1 of the chassis, and there is a gap between the half-shell I7-1 and the half-she...

Embodiment 2

[0099] Compared with Embodiment 1, the present embodiment differs in that:

[0100] The guide bar 7-43 set on the lower surface of the belt body is one; the ring groove I7-81 set in the middle of the belt roller 7-8 is adapted to it, and one is provided correspondingly; The annular groove II7-117 provided on the pulley 7-114 is also adapted to it, and one is provided correspondingly.

[0101] Protruding upper guide bars 7-42 are respectively provided on both sides of the upper surface of the belt body of the endless wide belt 7-4. The cross-sectional shape of the upper guide bar 7-42 is a trapezoid with a wide top and a narrow bottom, and the cross-sectional shape of the guide bar 7-43 is a trapezoid with a wide top and a narrow bottom.

[0102] The cross-sectional shape of the bump 7-41 is square, such as a rectangle or a square, and the height of the bump 7-41 from the surface of the belt body is 0.5 mm.

Embodiment 3

[0104] Compared with Embodiment 1, the present embodiment differs in that:

[0105] The connection between the upper section arm 7-132 and the lower section arm 7-134 of each group of ">" type crank arms 7-131 is at an angle of 30 degrees, and the pressure spring is a compression spring 7-19. The pressing arm 7-13 is connected to the fastening and pressing device II provided on the half-shell of the chassis, and the structure of the fastening and pressing device II includes a support plate 7-21, a screw rod II 7-20, and the support plate 7-21 is provided with a perforation, and the screw rod II 7-20 passes through the perforation to connect with the press arm 7-13, and the other end is sequentially covered with a compression spring 7-19 and a compression nut 7-18, The compression nut 7-18 is threadedly connected with the screw mandrel II 7-20 and supported on the compression spring 7-19 inside. like Figure 17 As shown in the figure, the structure of the pressurizing arm 7-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com