Glass tube necking inward-turning flange and manufacturing method and equipment thereof

A manufacturing method and glass tube technology, applied in glass manufacturing equipment, glass production, glass molding, etc., can solve the problems of low production efficiency and achieve the effects of simple structure, improved production efficiency, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

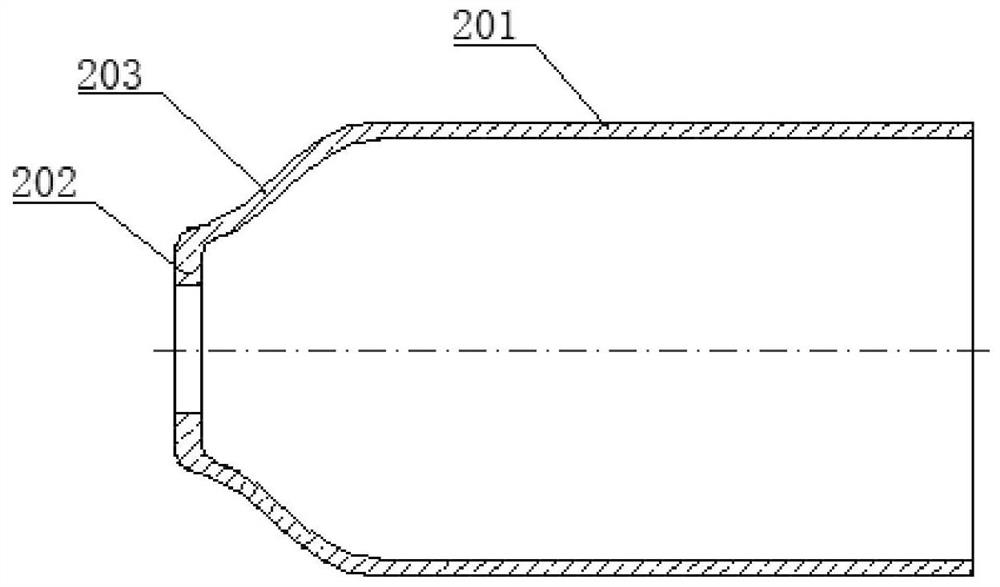

[0015] see figure 2 , a glass tube necking inward flange of the present invention, one end of the glass tube 201 reduces the diameter of the glass tube through a tapered mouth 203, and then makes an inward flat flange 202 at the necking, and the inward flat flange 202 The inner diameter can be as small as 12mm. According to the requirements of the heat-press sealing process, the thickness of the inward-turning flat flange 202 is 6-8 mm, and the plane (radial) width is 7-10 mm.

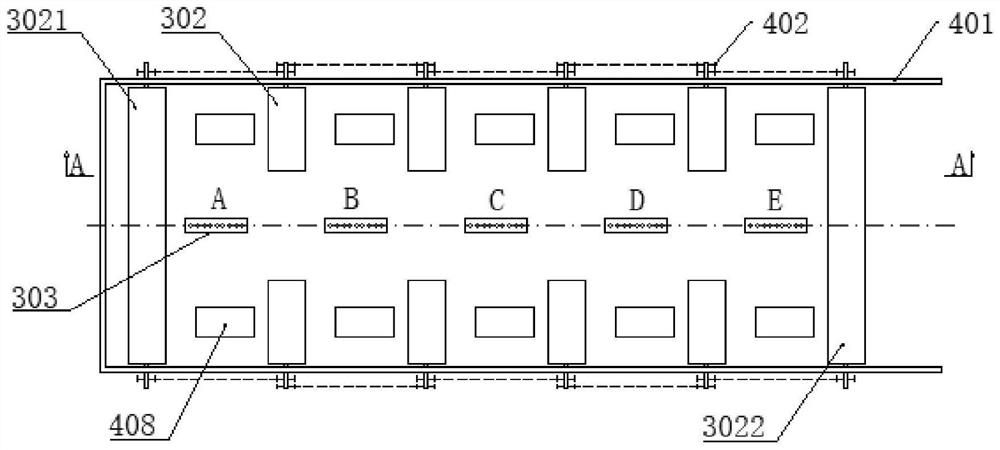

[0016] The basic equipment of making the glass tube necking inward flange of the present invention is as Image 6 with Figure 7 Shown, comprise molding die, cylinder 302 and heating fire head 303, molding die comprises by die 304 and convex die 305, the middle of die 304 is divided into two, opens from the glass tube two ends of 2 times of 201 glass tube lengths respectively Push the push rod 3041 at the end to the middle of the glass tube slowly, and the punch 305 translates from top to bottom th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com