Protective flux for aluminum-lithium alloy and preparation method of protective flux

A technology of aluminum-lithium alloy and flux, applied in the field of metallurgical smelting, can solve the problems of poor purification effect, easy oxidation of aluminum-lithium alloy, burning loss, etc., achieve good adsorption of impurities, good coverage and protection, and improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

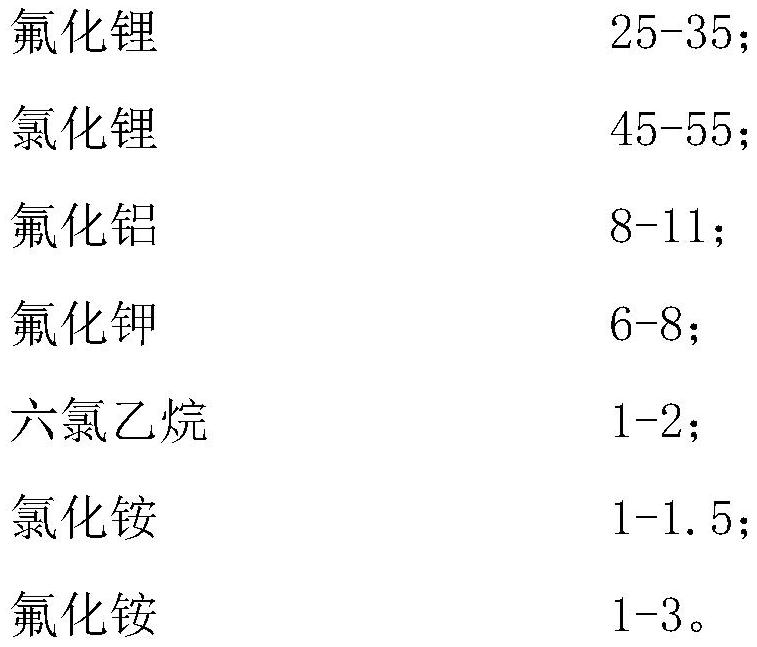

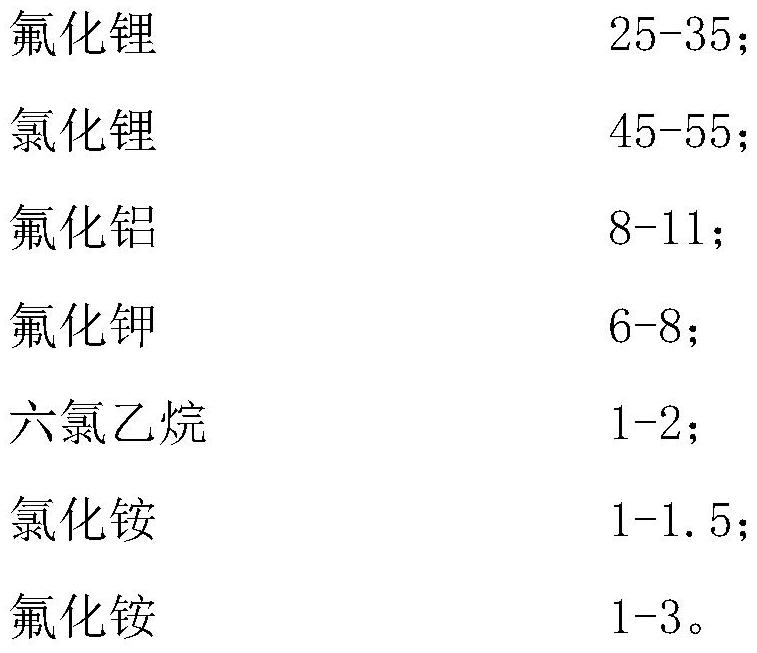

[0031] A protective flux for aluminum-lithium alloys, the raw materials include the following components: lithium fluoride, lithium chloride, aluminum fluoride, potassium fluoride, hexachloroethane, ammonium chloride and ammonium fluoride; the quality of the protective flux is The ratio is 29.5:51:9:7:1:1.5:1; the above raw materials all meet: purity ≥ 99.7%.

[0032] Lithium fluoride, lithium chloride, aluminum fluoride, and potassium fluoride powders were mixed in a three-dimensional mixer and placed in a crucible according to the above proportions, melted at 720°C for 20 minutes, condensed for 1.5 hours to about 20°C, and obtained Mixed blocks. Subsequently, the mixed block was mixed with hexachloroethane, ammonium chloride and ammonium fluoride, and ball milled for 2 hours, and the mixture was crushed and sieved to obtain granular flux. Then put it in an oven to dry for about 5 hours, take it out and ball mill it again for 2 hours, and then take out the material and seal ...

Embodiment 2

[0035] A protective flux for aluminum-lithium alloys, the raw materials include the following components: lithium fluoride, lithium chloride, aluminum fluoride, potassium fluoride, hexachloroethane, ammonium chloride and ammonium fluoride; the quality of the protective flux is The ratio is 33:49:7.5:7:1.5:1:1; the above raw materials all meet: purity ≥ 99.7%.

[0036] Lithium fluoride, lithium chloride, aluminum fluoride, and potassium fluoride powders were mixed in a three-dimensional mixer and placed in a crucible according to the above proportions, melted at 720°C for 20 minutes, condensed for 1.5 hours to about 20°C, and obtained Mixed blocks. Subsequently, the mixed block was mixed with hexachloroethane, ammonium chloride and ammonium fluoride, and ball milled for 2 hours, and the mixture was crushed and sieved to obtain granular flux. Then put it in an oven to dry for about 5 hours, take it out and ball mill it again for 2 hours, and then take out the material and seal ...

Embodiment 3

[0039] A protective flux for aluminum-lithium alloys, the raw materials include the following components: lithium fluoride, lithium chloride, aluminum fluoride, potassium fluoride, hexachloroethane, ammonium chloride and ammonium fluoride; the quality of the protective flux is The ratio is 25.5:53:11:9:2:1.5:3; the above raw materials all meet: purity ≥ 99.7%.

[0040] Lithium fluoride, lithium chloride, aluminum fluoride, and potassium fluoride powders were mixed in a three-dimensional mixer and placed in a crucible according to the above proportions, melted at 720°C for 20 minutes, condensed for 1.5 hours to about 20°C, and obtained Mixed blocks. Subsequently, the mixed block was mixed with hexachloroethane, ammonium chloride and ammonium fluoride, and ball milled for 2 hours, and the mixture was crushed and sieved to obtain granular flux. Then put it in an oven to dry for about 5 hours, take it out and ball mill it again for 2 hours, and then take out the material and seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com