Pressure steel pipe contact grouting void detection method and device

A penstock, contact grouting technology, applied in sustainable construction, climate sustainability, infrastructure testing, etc., can solve problems such as difficulty in grouting quality inspection, and achieve low cost, simple instrument erection, and simple and easy-to-obtain devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

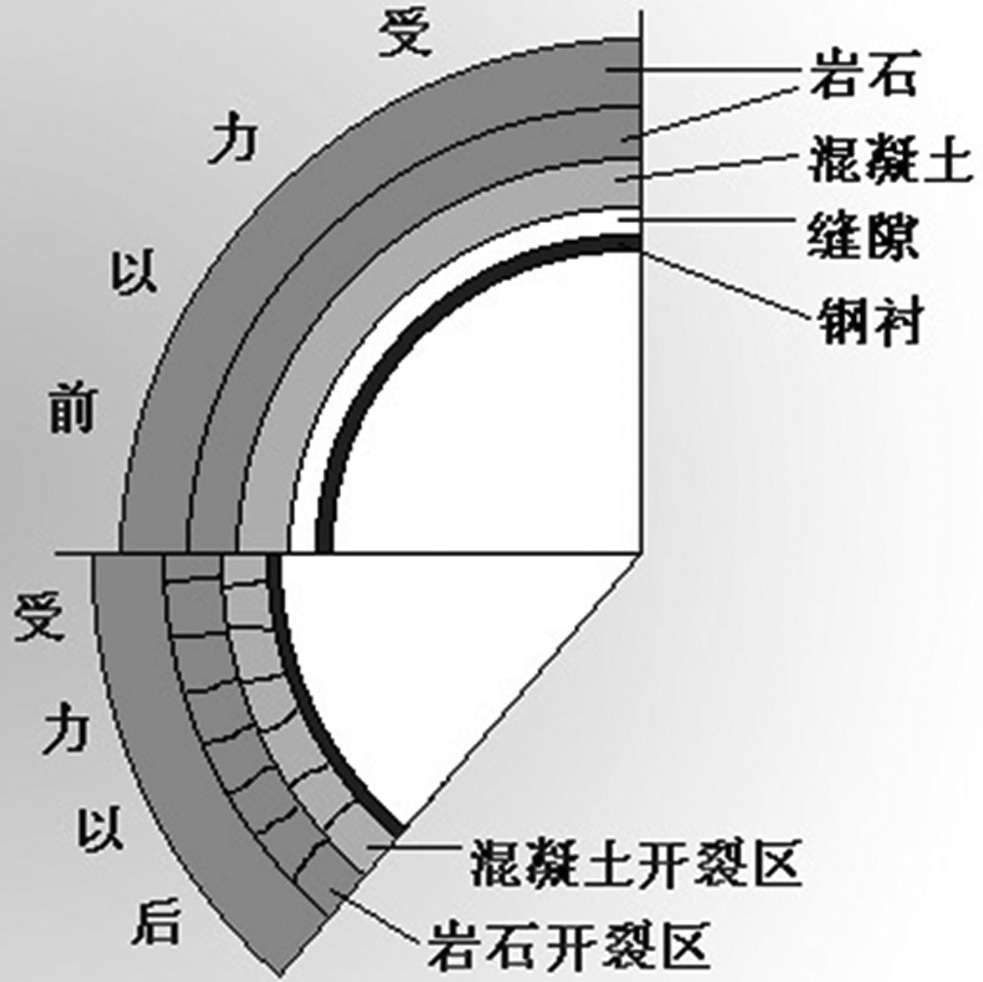

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

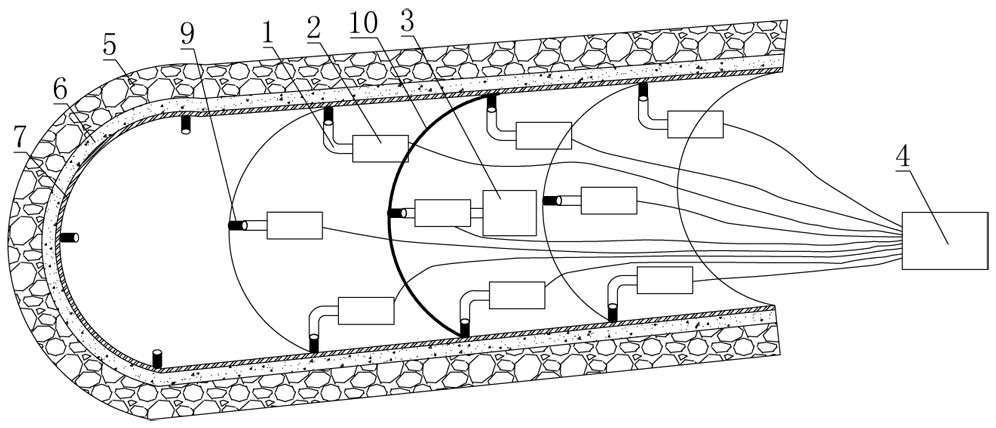

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0034] Such as Figure 3 ~ Figure 5 As shown, this embodiment provides a method for detecting voids in contact grouting of penstocks, including:

[0035] Step 1: Check whether the grouting hole on the penstock is blocked. If the grouting hole is blocked by concrete, it is advisable to use a percussion drill with a drill bit diameter slightly smaller than the inner diameter of the grouting hole to dredge it. The drilling depth should be slightly greater than the length of the grouting pipe. But do not drill into the surrounding rock formation;

[0036] Step 2: Select the section to be detected;

[0037] Step 3: Select a grouting hole on the section to be detected as the air inlet hole, and the other grouting holes on the section to be detected that are not used as the air inlet hole and the grouting holes on the adjacent sections of the section to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com