Efficient and self-locking electronic mechanical brake

An electro-mechanical braking and self-locking technology, applied in the type of brake, the brake on the axial direction, the components of the brake, etc., can solve the problem of not meeting the requirements of smooth transmission, low noise, inability to automatically adjust the braking gap, and high requirements for motor braking. Advanced problems, to achieve the effect of ingenious structural design, low noise and high coincidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

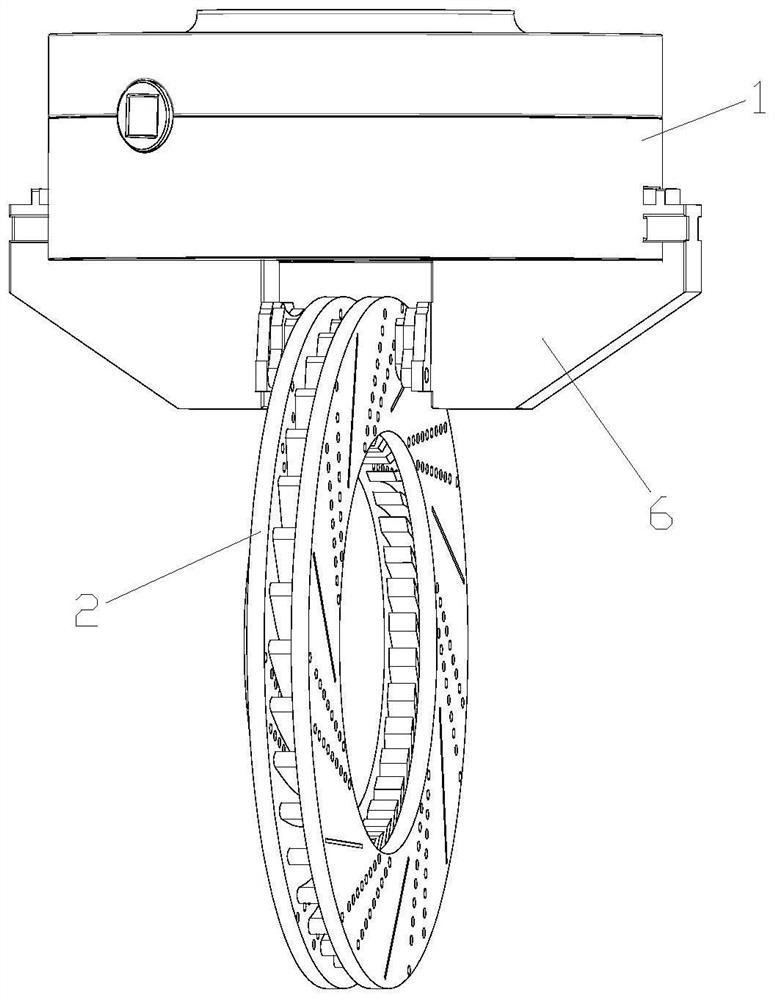

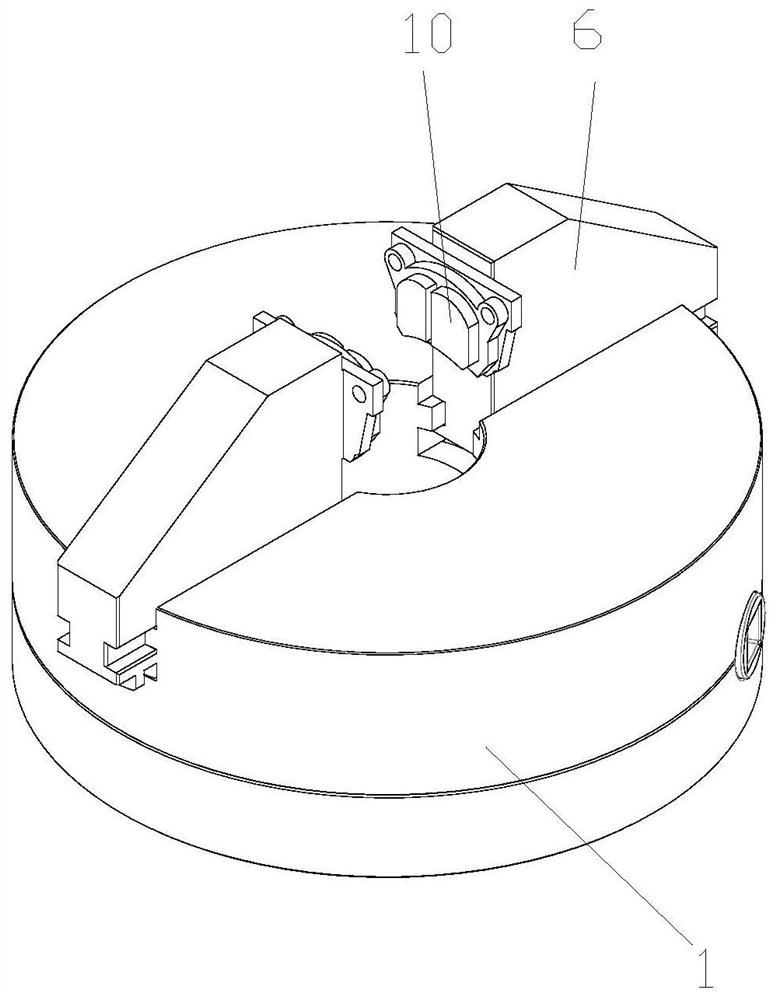

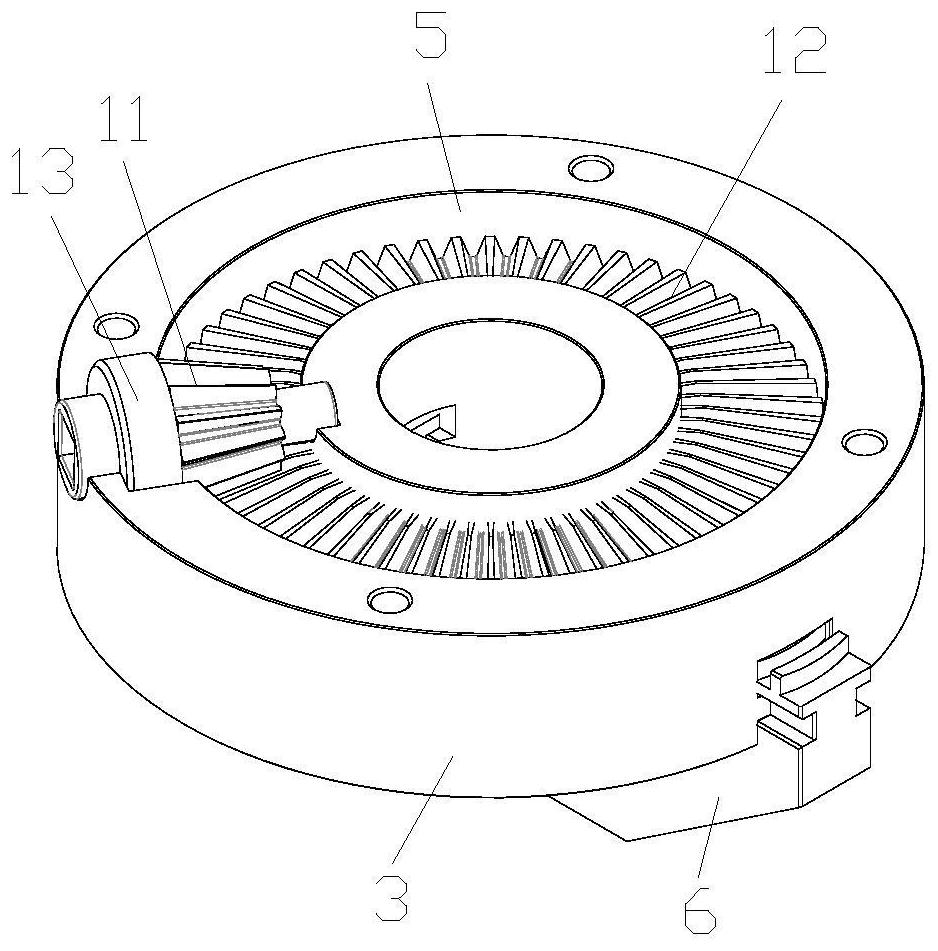

[0028] see Figure 1 to Figure 7 , this embodiment discloses a high-efficiency, self-locking electromechanical brake, including a brake box 1 fixedly connected to the frame, a brake disc 2 fixedly connected to the wheel, the brake box 1 is composed of a brake box body 3 and a The brake case 3 is fixedly connected with the brake case cover 4, and the brake case 3 and the brake case cover 4 jointly form an annular installation cavity 5. Two left and right brake calipers 6 are arranged on the bottom of the brake box 1 , and the brake calipers 6 can only slide back and forth along the left and right direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com