Pipeline structure capable of preventing scouring and flow accelerated corrosion and changing flow direction of fluid

A flow-accelerated corrosion and fluid technology, applied to pipes, pipe components, branch pipelines, etc., can solve problems such as inability to prevent or eliminate pipeline corrosion, achieve convenient procurement and acquisition, reduce erosion and flow-accelerated corrosion, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but these descriptions are only exemplary and not intended to limit the protection scope of the present invention.

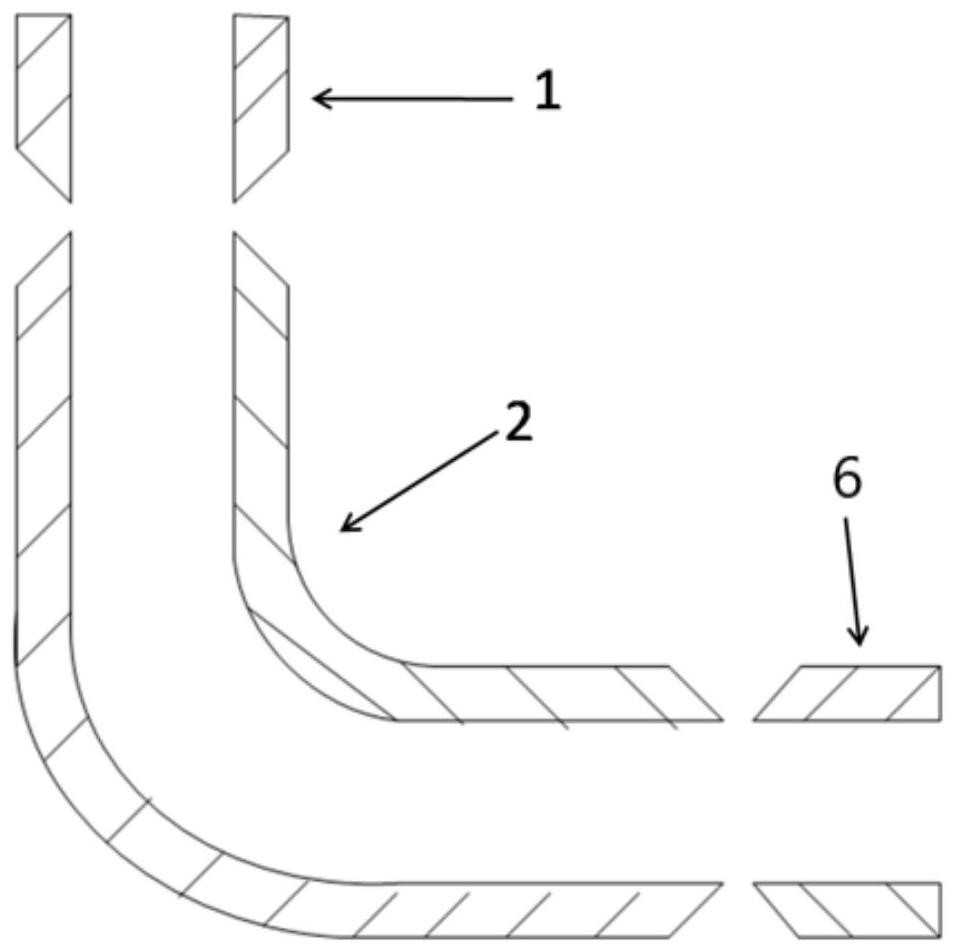

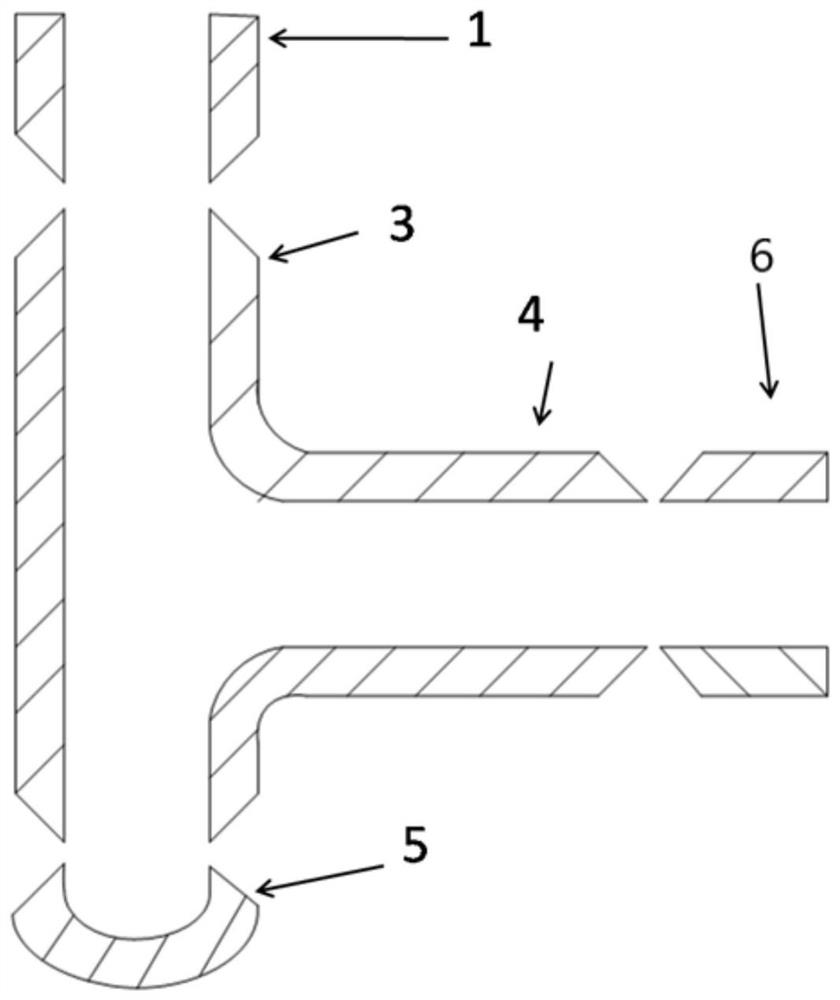

[0024] Such as figure 2 As shown, the pipeline structure for changing the direction of fluid flow provided by the present invention to prevent erosion and accelerated flow corrosion mainly includes a first straight pipe section 1, a tee, a spherical head 5 and a second straight pipe section 6, wherein the three The pass includes a tee shoulder joint 3 and a tee foot joint 4, one end of the tee shoulder joint 3 is connected to the first straight pipe section 1, and the other end of the tee shoulder joint 3 is connected to the spherical head 5 Connection, the three-way foot joint 4 is connected with the second straight pipe section 6 .

[0025] The first straight pipe section 1 is welded to one end of the tee shoulder joint 3, and a groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com