Solid particle heat storage and release system of multistage fluidized bed

A solid particle, fluidized bed technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as large fluctuations in power generation load and difficulty in ensuring heat supply quality, and achieve release transfer efficiency. High, improve the effect of operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

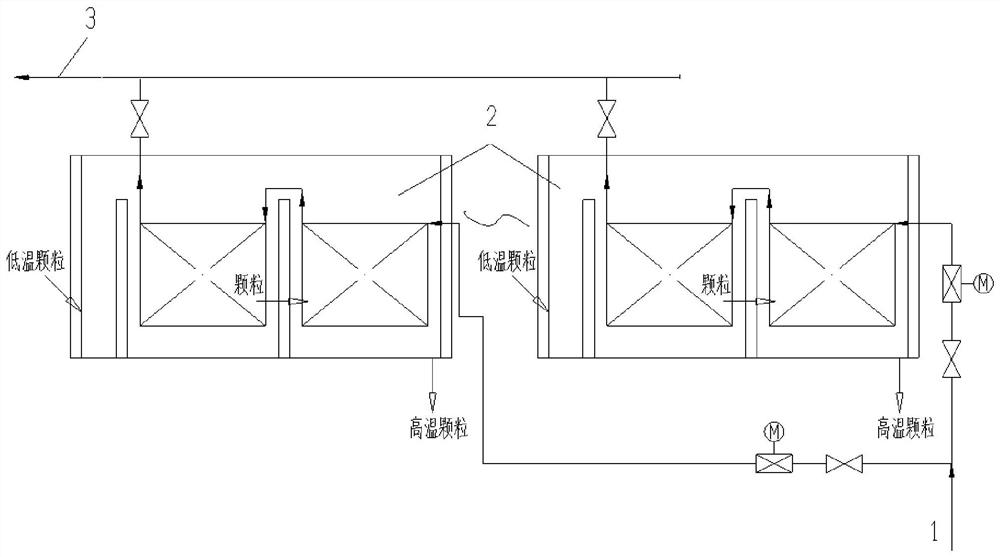

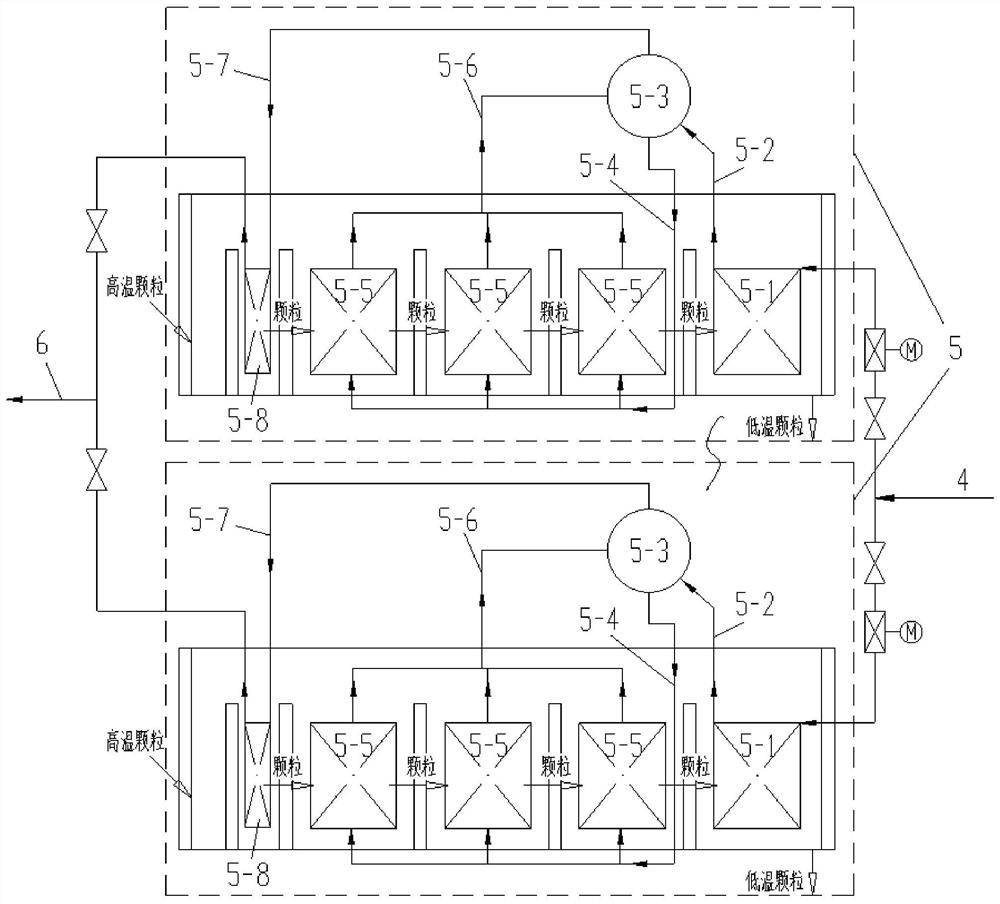

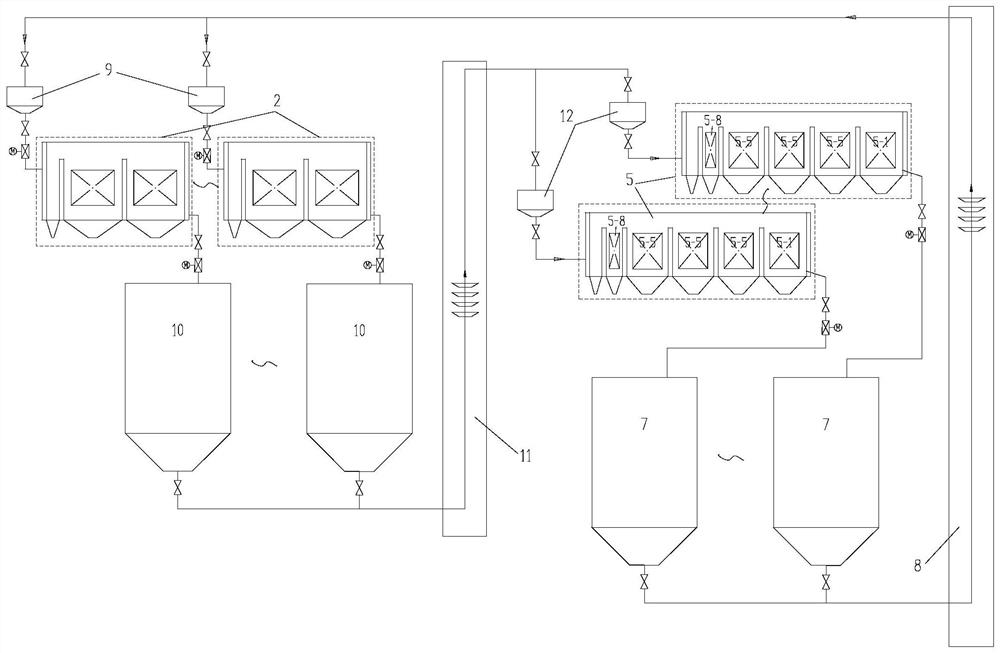

[0036] In this embodiment, a multi-stage fluidized bed solid particle heat storage and release system is specifically provided, which can be used not only for in-service generating units, but also for newly built generating units.

[0037] The system mainly includes: heat storage and heat exchange subsystem, heat release heat exchange subsystem, particle transportation subsystem, connecting pipes between subsystems and related valve accessories on each pipe, etc. The main principle is to use solid particle storage Heat, the thermal energy of high-temperature steam is converted into sensible heat of solid particles for storage. The storage temperature is high, which can meet the demand for industrial steam supply with higher parameters. At the same time, the release and transfer of stored heat are realized through heat exchange, and the energy storage and transfer efficiency is high. Among them, in actual application, solid particles can be selected locally, such as sand and gra...

Embodiment 2

[0065] In the multi-stage fluidized bed solid particle heat storage and release system provided in Example 1, its heat storage and heat exchange subsystem uses steam extraction from the unit to heat low-temperature solid particles into high-temperature solid particles, while in this embodiment, it uses After the high-temperature main steam / generating unit generates electricity, the solid particles are heated by electric heaters, and electric heating tubes are arranged in each of the heat storage heat exchangers, and the low-temperature solid particles are heated to high-temperature solid particles under the action of the electric heating tubes , in order to realize the storage of heat and realize the deep peak regulation function of the unit.

Embodiment 3

[0067] In the multi-stage fluidized bed solid particle heat storage and release system provided in Example 1, it provides fluidized air through the fluidized fan configured in the system, and circulates the fluidized air to reduce the heat loss of the fluidized air. In this embodiment, the fluidizing air used is changed to the hot secondary air from the boiler, and the solid particles are fluidized and directly go to the furnace (no need to return and recycle), thereby reducing the selection requirements of the fluidizing fan. For details, see Figure 6 , Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com