High-precision displacement sensor

A displacement sensor, high-precision technology, applied in the field of sensors, can solve the problems of low magnetomechanical coupling coefficient, affect the echo signal strength, and high eddy current loss, and achieve the effects of low eddy current loss, elimination of reflected waves, and strong echo signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

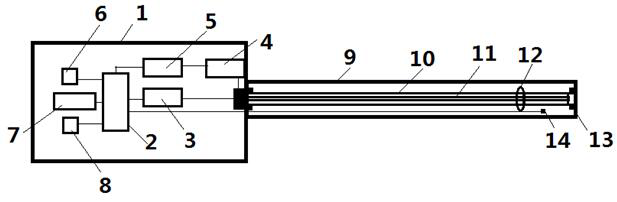

[0018] A high-precision displacement sensor, including an electronic chamber 1, a microprocessor 2, an excitation pulse circuit 3, an echo acquisition circuit 4, an echo analysis circuit 5, a communication module 6, a display screen 7, a time measurement circuit 8, and a measuring rod 9 , aluminum casing 10, waveguide wire 11, moving magnetic ring 12; the electronic chamber 1 includes an excitation pulse circuit 3 connected to a microprocessor 2, an echo analysis circuit 5, a communication module 6, a display screen 7, and a time measurement circuit 8; the echo acquisition circuit 4 is respectively connected to the echo analysis circuit 5 and the waveguide wire 11; the waveguide wire 11 is connected to the excitation pulse circuit 3, which is encapsulated in the aluminum casing 10, and is provided with a moving magnetic ring 12 in the middle; to eliminate The reflected wave increases the strength of the detection signal, and damping elements 13 are provided at both ends of the ...

Embodiment 2

[0021] A high-precision displacement sensor, including an electronic chamber 1, a microprocessor 2, an excitation pulse circuit 3, an echo acquisition circuit 4, an echo analysis circuit 5, a communication module 6, a display screen 7, a time measurement circuit 8, and a measuring rod 9 , aluminum casing 10, waveguide wire 11, moving magnetic ring 12; the electronic chamber 1 includes an excitation pulse circuit 3 connected to a microprocessor 2, an echo analysis circuit 5, a communication module 6, a display screen 7, and a time measurement circuit 8; the echo acquisition circuit 4 is respectively connected to the echo analysis circuit 5 and the waveguide wire 11; the waveguide wire 11 is connected to the excitation pulse circuit 3, which is encapsulated in the aluminum casing 10, and is provided with a moving magnetic ring 12 in the middle; to eliminate The reflected wave increases the strength of the detection signal, and damping elements 13 are provided at both ends of the ...

Embodiment 3

[0024] A high-precision displacement sensor, including an electronic chamber 1, a microprocessor 2, an excitation pulse circuit 3, an echo acquisition circuit 4, an echo analysis circuit 5, a communication module 6, a display screen 7, a time measurement circuit 8, and a measuring rod 9 , aluminum casing 10, waveguide wire 11, moving magnetic ring 12; the electronic chamber 1 includes an excitation pulse circuit 3 connected to a microprocessor 2, an echo analysis circuit 5, a communication module 6, a display screen 7, and a time measurement circuit 8; the echo acquisition circuit 4 is respectively connected to the echo analysis circuit 5 and the waveguide wire 11; the waveguide wire 11 is connected to the excitation pulse circuit 3, which is encapsulated in the aluminum casing 10, and is provided with a moving magnetic ring 12 in the middle; to eliminate The reflected wave increases the strength of the detection signal, and damping elements 13 are provided at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com