Integrated mechanical workboat and wind power complete machine construction method based on same

A technology of mechanical construction and complete machine, applied in ship accessories, transportation and packaging, devices to prevent multi-way movement of goods, etc. and risks, so as to alleviate the coupling effect of relative motion, reduce the technical difficulty of transportation, and shorten the construction period of offshore construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to further understand the content, characteristics, and effects of the present invention, it will be described in detail with reference to the accompanying drawings:

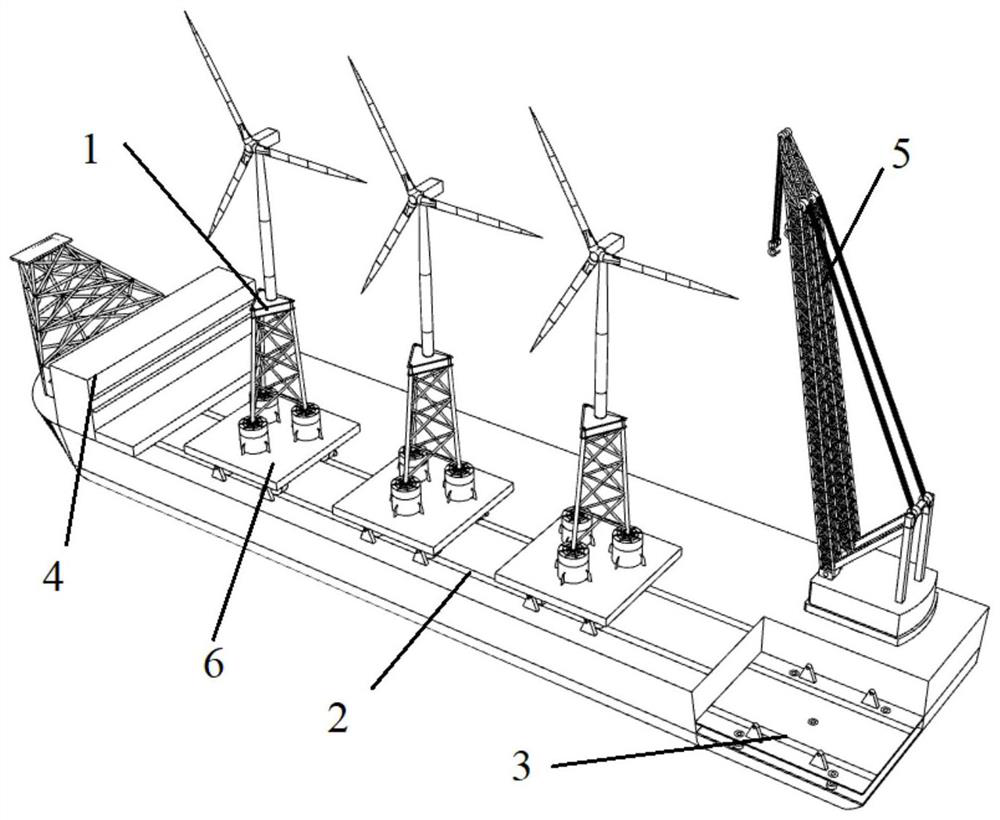

[0057] like figure 1 As shown, the present invention provides an integrated mechanical construction boat 4, and provides a construction method of the multi-cylindrical construction boat based on the integrated mechanical construction boat 4, which can be transported by integrated mechanical construction boat 4. Installing and recovering the base wind turbine 1.

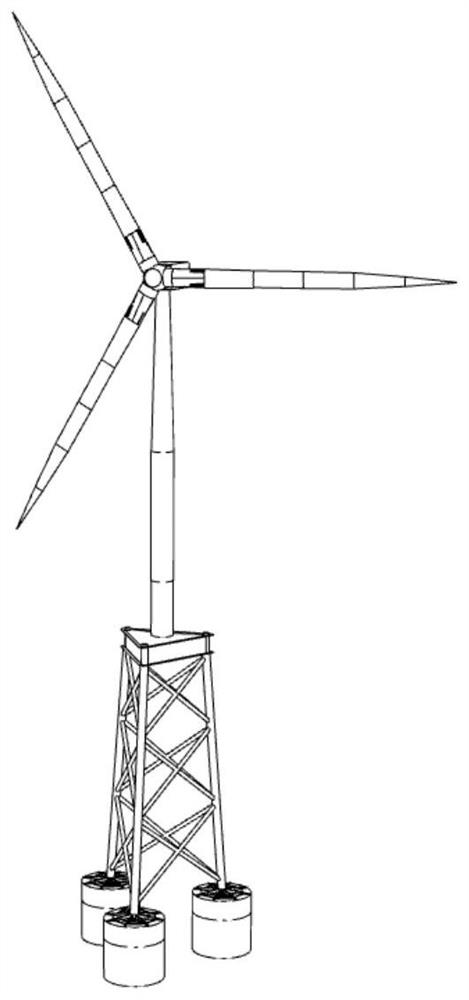

[0058] like figure 2 As shown, the multi-cylindrical bracket base wind turbine 1 generally includes three to four suction cylinders, and the plurality of suction cylinders are connected to the catheter frame through the upper cylindrical top reinforcing sections. The suction barrel body is a steel cylinder, consisting of a wall and a cover. The cover of the suction cylinder is uniformly arranged with a plurality of ventilation / apertures, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com