Long-barrel plastic film bag for garbage can and packaging method and packaging mold of long-barrel plastic film bag

A technology of plastic film bags and packaging methods, which is applied in the direction of garbage cans, household appliances, garbage collection, etc., can solve the problems of rigid packaging boxes that cannot be compressed, unreasonable packaging design, and serious environmental pollution, and achieve low cost of container materials, Improve user experience and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

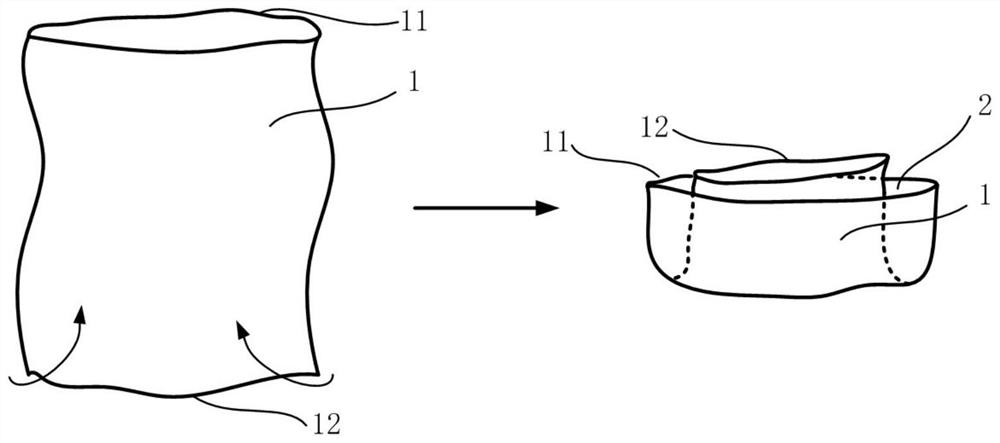

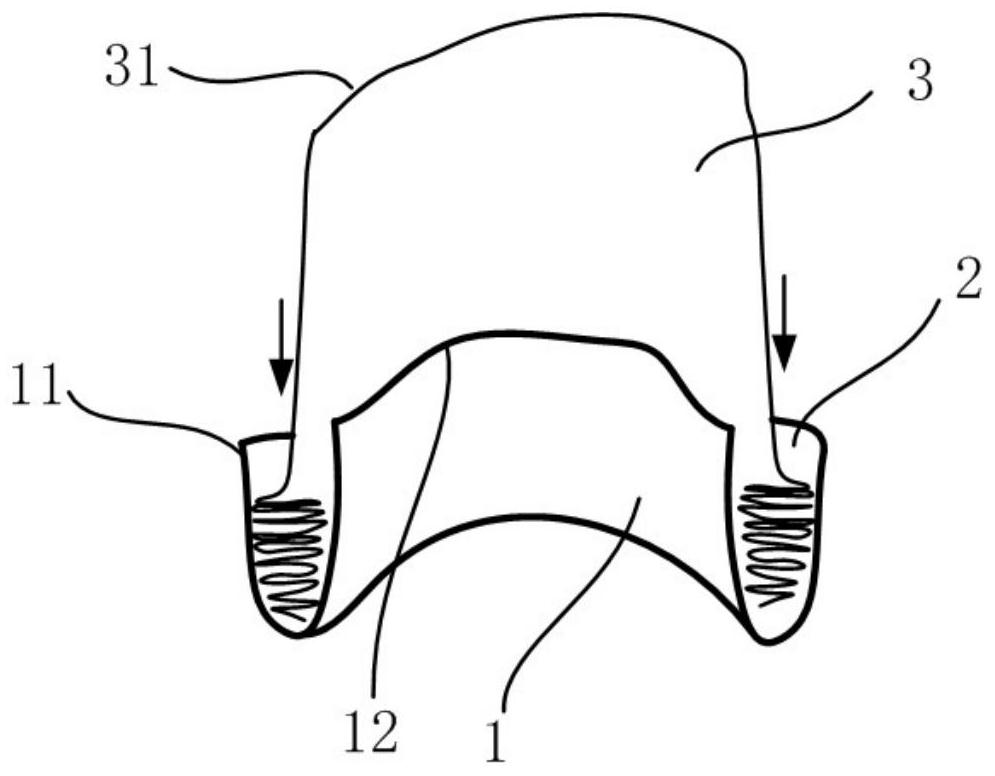

[0051] Such as Figure 1-12 A long-tube plastic film bag for a trash can as shown, comprises a long-tube plastic film bag body 3 and an outer package packaged outside the long-tube plastic film bag body 3, and in the present invention, the outer package is a film tube material 1. The film cartridge 1 includes a first opening 11 and a second opening 12, an annular first groove 2 is formed between the first opening 11 and the second opening 12, and the long plastic film bag body One end of 3 is an open end, and the other end of the long tube plastic film bag body 3 is a sealing end 32, and the long tube plastic film bag body 3 is folded toward the open end and accommodated in the first groove 2, and the long tube plastic film bag body 3 is folded toward the open end and stored in the first groove 2. The sealing end 32 of the film bag body 3 extends out of the first groove 2 of the film casing 1, the first opening 11 of the film casing 1, the long plastic film bag body 3 and the ...

Embodiment 2

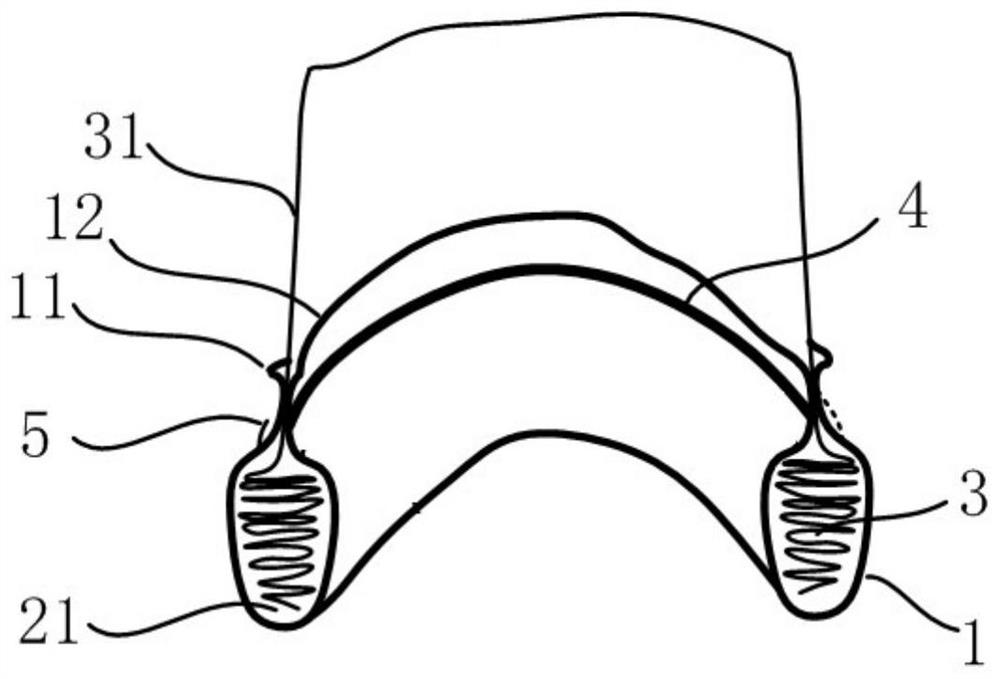

[0070] Such as Figure 6 to Figure 7 As shown, the connection line 4 is annular, and is formed by thermal melting or bonding. After the end 31 of the long plastic film bag body 3 is sealed, the sealing end 32 of the long plastic film bag body 3 is formed. Sealing end 32 is exactly the first bag bottom of this long tube plastic film bag body 3, in order to use this flexible packaging long tube plastic film bag conveniently, as Figure 6and Figure 7 As shown, the first opening 11 side of the film casing 1 is provided with a first easy-tear line 5 below the connecting line 4, and the second opening 12 side of the film casing 1 is below the connecting line 4 A second easy-tear line 6 is provided. Such as Figure 8 As shown, when in use, the continuous long tube plastic film bag of flexible packaging is completely inserted into the second groove 94 of the trash can 9, the first easy-tear line 5 and the second easy-tear line 6 are torn off, and the cover is covered 95. Then by...

Embodiment 3

[0072] The connection line 4 is straight and is formed by thermal melting or bonding. The connection line 4 is the sealing end 32, which is also the first bag bottom of the long plastic film bag body 3. In order to use the flexible package The long-tube plastic film bag is convenient, and the connecting line 4 is provided with a first easy-to-tear line 5 below the side of the first opening 11 of the film tube material 1 . A first easy-to-tear line 5 is provided below the connecting line 4 on the side of the first opening 11 of the film tube material 1 . When in use, the continuous long tube plastic film bag of flexible packaging is completely inserted into the second groove 94 of the trash can 9, the first easy-to-tear line 5 is torn off, and the cover plate 95 is covered. Then by manual or automatic mode, the bottom of the first bag of the elongated plastic film bag body 3 is packed in the trash can 9, and others are the same as in embodiment 1. In this way, when the film tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com