Wheel-rail contact geometric parameter measurement method

A Technology of Contact Geometry and Parameter Measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

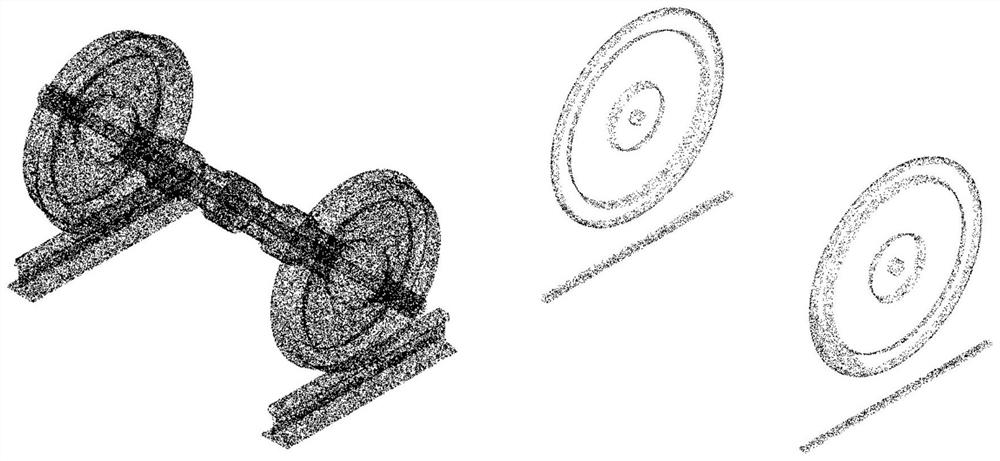

Image

Examples

Embodiment

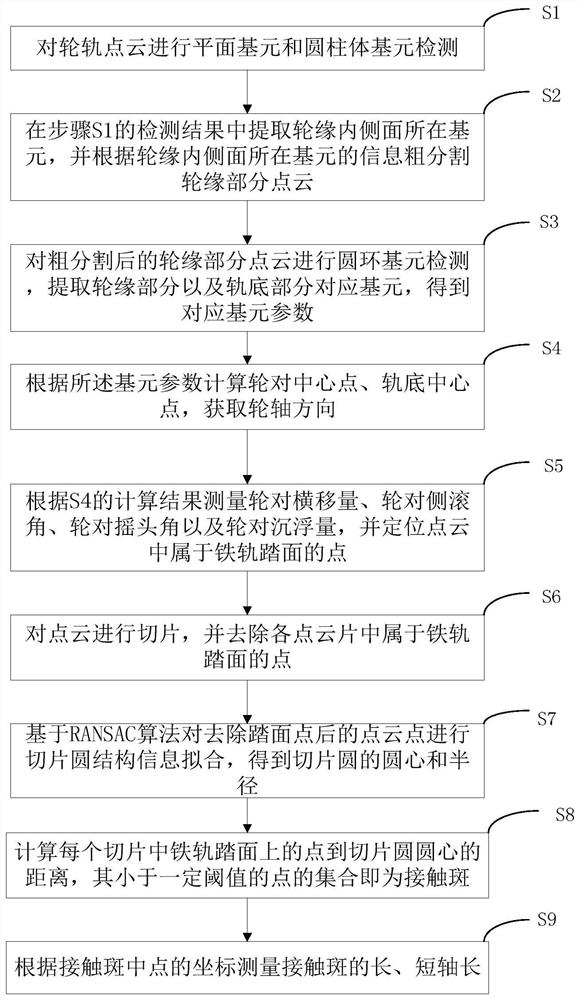

[0059] figure 1 A schematic flow chart of a method for measuring wheel-rail contact geometric parameters provided in this embodiment, refer to figure 1 , the method includes the following steps:

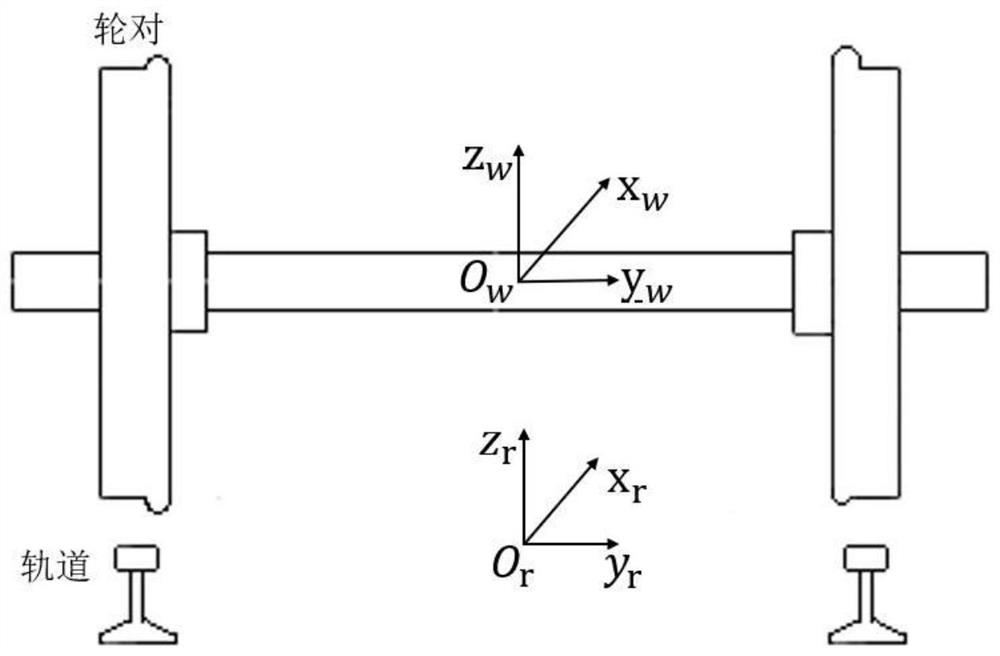

[0060] Process the wheel-rail point cloud data to establish two different coordinate systems for the wheel set and the track, figure 2 It is the structure schematic diagram of two kinds of coordinate systems of this embodiment, refer to figure 2 , to establish O with the center point of the wheel set axle as the origin w -X w Y w Z w The wheel pair coordinate system, the wheel pair coordinate system moves with the wheel pair relative to the track; the center point of the center of the rail surface on both sides is used as the origin to establish O r -X r Y r Z r The accompanying coordinate system, so that the plane where the rail bottom is located and the accompanying coordinate system O r -X r Y r Z r X in r o r Y r plane parallel, where X r is the horizontal exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com