Method for shielding surface leakage current of lightning arrester

A surface leakage and lightning arrester technology, which is applied in the field of lightning arresters, can solve problems such as the influence of measurement results, achieve the effects of reducing equipment operation and maintenance work, preventing falling, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

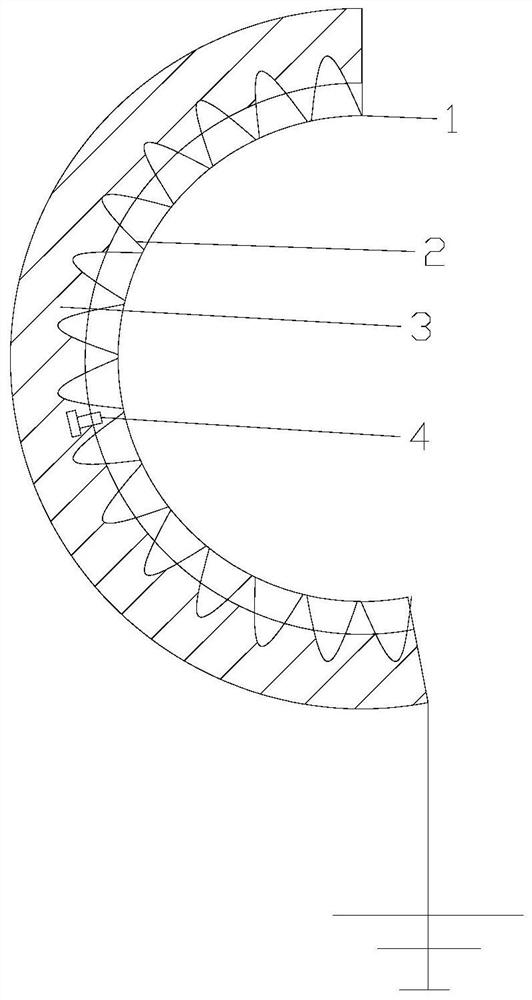

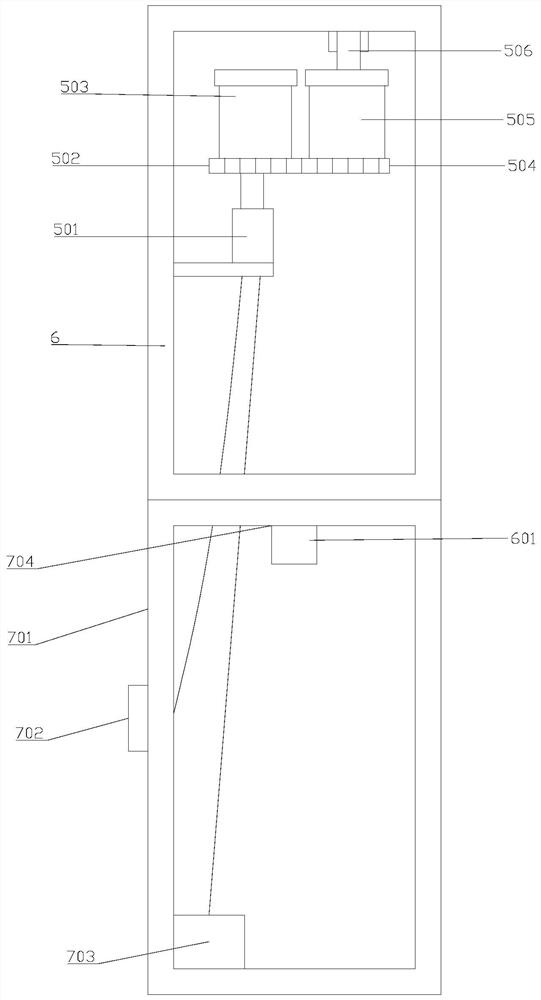

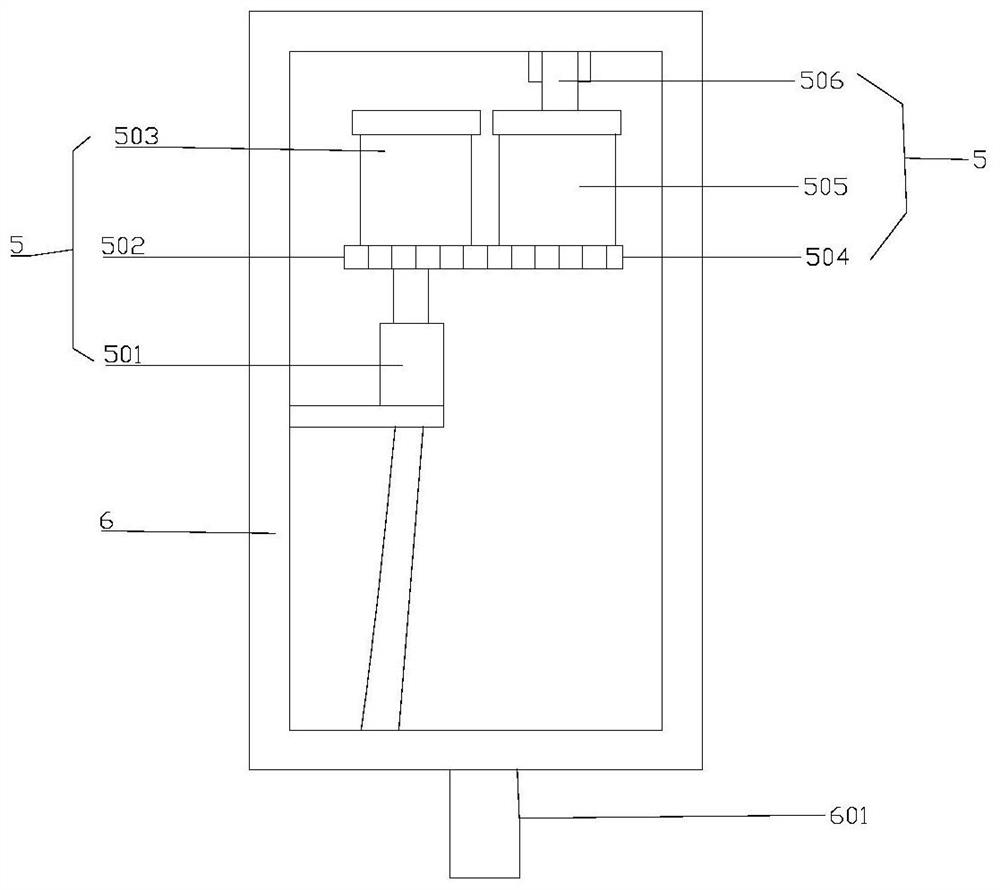

[0046] refer to figure 1 , figure 2 , image 3 and Figure 4 , figure 1 It is a schematic structural diagram of a grounding component in a method for shielding the surface leakage current of an arrester provided in an embodiment of the present invention, figure 2 It is a schematic structural diagram of the connection between the first box body 6 and the second box body 7 in a method for shielding the surface leakage current of the arrester provided by the embodiment of the present invention, image 3 It is a schematic structural diagram of the first box in a method for shielding the surface leakage current of a lightning arrester provided by an embodiment of the present invention, Figure 4 It is a schematic structural diagram of the second box body in a method for shielding the surface leakage current of a lightning arrester provided by an embodiment of the present invention. The device includes:

[0047] A grounding component is used to be sleeved on the arrester, and t...

Embodiment 2

[0085] A method for shielding surface leakage current of an arrester, comprising the following steps:

[0086] S1. Set the grounding component on the arrester, and the grounding end of the grounding component is grounded;

[0087] S2. The first box body 6 is set on the second box body 7 to increase the measurement height, and then the two ends of the grounding assembly are connected to the drive assembly 5 inside the first box body, and the drive assembly 5 is turned on, and the drive assembly 5 works , The drive assembly 5 is stretched so that the drive assembly 5 is closely attached to the arrester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com