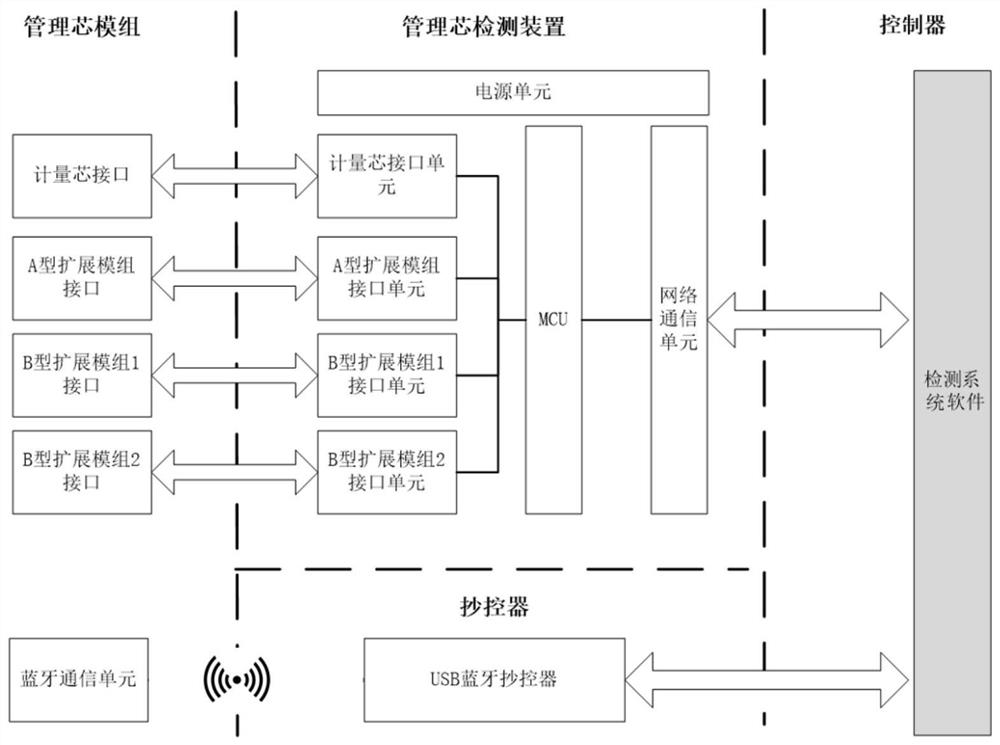

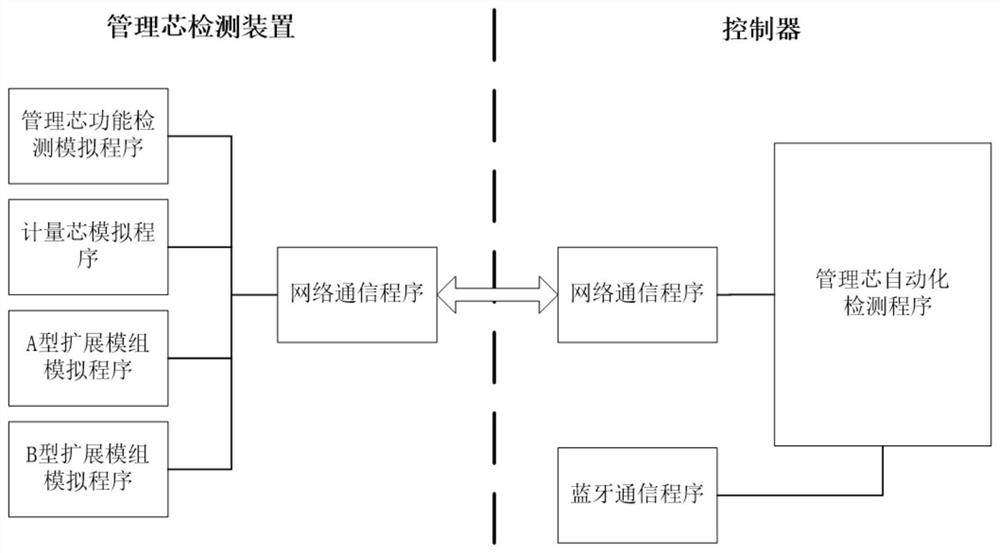

Automatic detection system and method for management core of intelligent instrumented electric energy meter

An intelligent IoT and automatic detection technology, applied in measurement devices, measuring electrical variables, instruments, etc., can solve the problem that it cannot adapt to the detection requirements of intelligent IoT energy meters, does not support flexible setting of operating detection parameters, and cannot manage core interface function verification. and other problems, to achieve the effect of simple and flexible implementation and operation, improving software reliability and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Detect the data consistency between the management core and the metering core: verify whether the real-time synchronization of the operating data such as the total and each phase active power, reactive power, power factor, phase voltage, phase current, and grid frequency to the management core is normal, and whether there is an excess Error jumps, including:

[0137] Step (1): Set the total and individual phase active power, reactive power, power factor, individual phase voltage, individual phase current, grid frequency and other operating data through the automatic detection program of the management core at the controller end;

[0138] Step (2): The automatic detection program of the management core at the controller sends the set real-time operation data to the management core detection device through the network communication unit. Set running data, waiting for the management core to perform data synchronization;

[0139] Step (3): The management core module active...

Embodiment 2

[0144] Detect the data consistency between the management core and the metering core: verify the carry relationship of the pulse constant, power decimal and integer under normal power-on conditions, including:

[0145] Step (1): Preset the detection conditions through the automatic detection program at the controller end: the reference voltage Un is set to 220V, the meter constant is set to 400imp / kWh, the turning current is set to 0.04A, the minimum current is set to 0.4A, The maximum current is set to 60A (the set value is consistent with the corresponding table type of the management core program to be tested);

[0146] Step (2): Clear the pulse count in the automatic detection program of the controller end management core;

[0147] Step (3): Turn on the corresponding data consistency detection scheme preset in the automatic detection program of the management core at the controller end, and carry forward current, and take 1 pulse, 2 pulses, 3 pulses, and 4 pulses at interv...

Embodiment 3

[0155] Detect whether the metering data processing function of the management core is normal: the management core has a time-of-use metering function, and the active and reactive electric energy should be accumulated and stored separately for each tariff period and the total electric energy, specifically including:

[0156] Step (1): Initialize the parameters in the automatic detection program of the controller end management core;

[0157] Step (2): Preset the detection conditions through the automatic detection program at the controller end: the reference voltage Un is set to 220V, the meter constant is set to 400imp / kWh, the turning current is set to 0.04A, the minimum current is set to 0.4A, The maximum current is set to 60A (the set value is consistent with the corresponding table type of the management core program to be tested);

[0158] Step (3): Set voltage U=220V, current I=1A, power angle 60° through the automatic detection program of the management core at the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com