Single-polarization low-loss hollow-core negative-curvature optical fiber

A low-loss, single-polarization technology, applied in polarized fibers, clad fibers, optics, etc., can solve the problems of low damage resistance threshold, small effective mode field area, high dispersion and nonlinear effects, and achieve the goal of reducing transmission loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

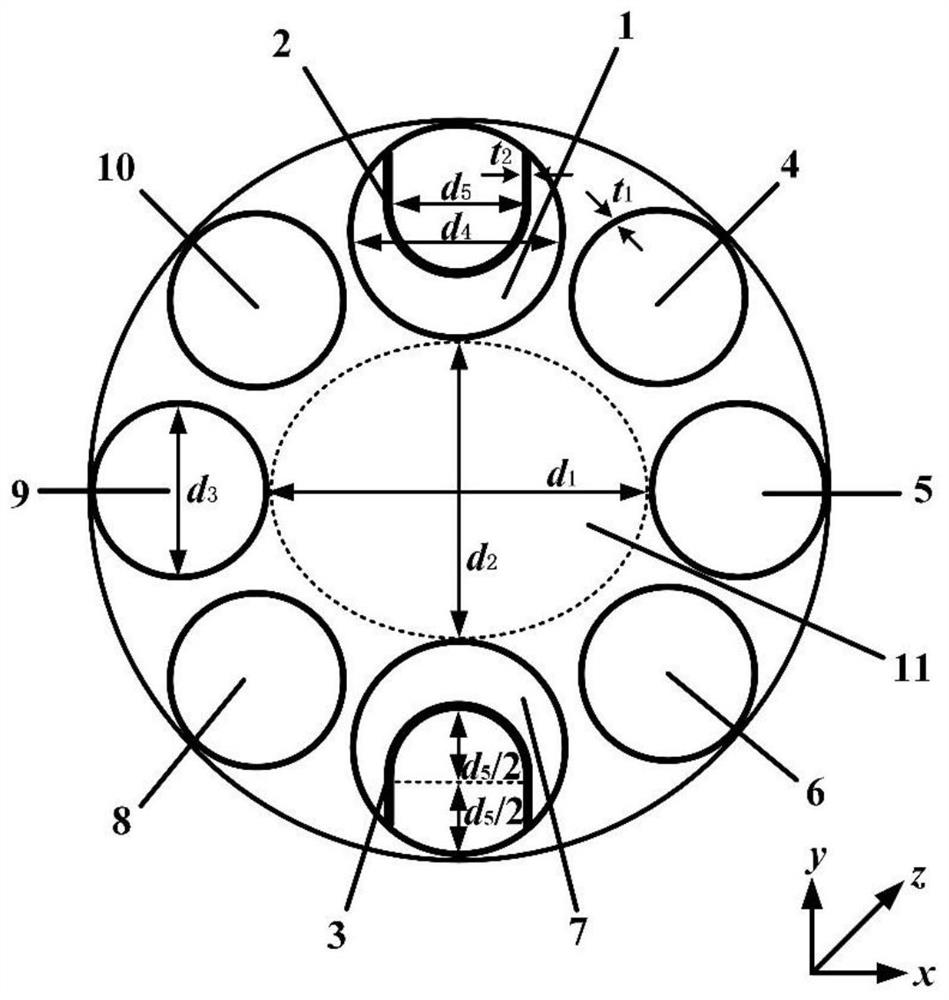

[0052] Embodiment 1: The major axis d of the elliptical core region 1 is: 53μm, the minor axis d of the elliptical core region 2 For: 45μm. The diameter d of the two circular cladding tubes 4 For: 29μm. The diameter d of the semicircular portion of the two U-shaped nesting rings 5 is: 20 μm, the maximum distance d between the bottom of the U-shaped nesting ring and the inner wall of the circular cladding tube 5 For: 20μm. The diameter d of the six circular cladding tubes 3 For: 25μm. the t 1 For: 1.116μm. the t 2 For: 1.506μm. The angle between adjacent tubes of the eight quartz-clad tubes is 44.6 degrees.

Embodiment 2

[0053] Embodiment 2: The major axis d of the elliptical core region 1 is: 55μm, the minor axis d of the elliptical core region 2 For: 47μm. The diameter d of the two circular cladding tubes 4 For: 31μm. The diameter d of the semicircular portion of the two U-shaped nesting rings 5 is: 22 μm, the maximum distance d between the bottom of the U-shaped nesting ring and the inner wall of the circular cladding tube 5 For: 22μm. The diameter d of the six circular cladding tubes 3 For: 26μm. the t 1 For: 1.118μm. the t 2 For: 1.508μm. The angle between adjacent tubes of the eight quartz-clad tubes is 45.4 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness range | aaaaa | aaaaa |

| Wall thickness range | aaaaa | aaaaa |

| Diameter range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com