A Continuous Zoom Optical System with External Entrance Pupil

An optical system and light technology, applied in the field of continuous zoom optical system, can solve the problems of not having continuous zoom function, not having built-in diaphragm, not having external entrance pupil, etc., achieving small system size, compact structure, and changing center of mass small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

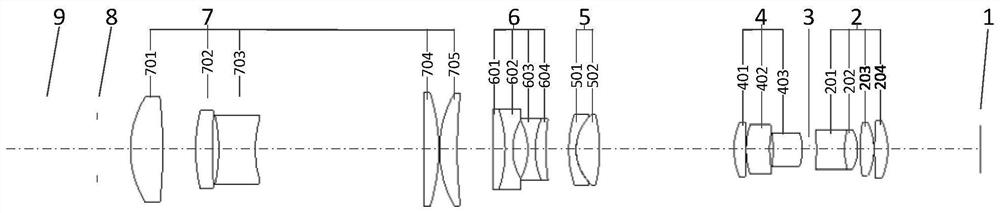

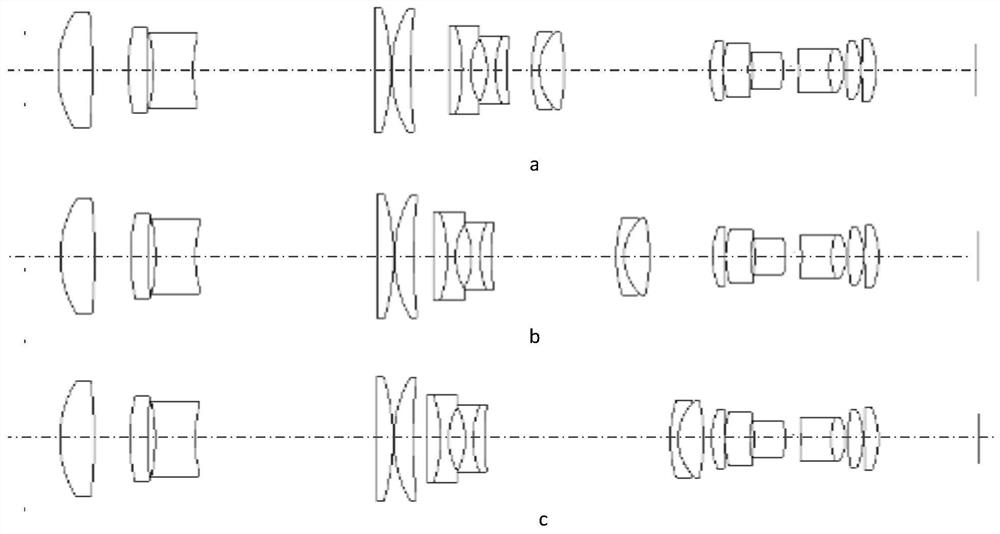

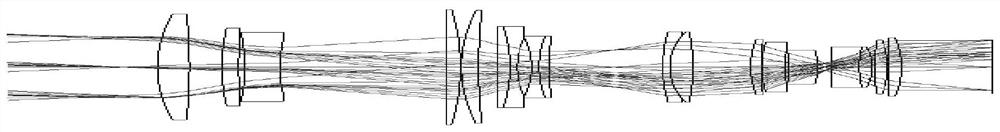

[0069] Such as figure 1 As shown, a continuous zoom optical system with an external entrance pupil defines that the light is incident from left to right. Group 6, compensation mirror group 5, relay mirror group 4, diaphragm 3 and rear fixed mirror group 2; the left side of the front fixed mirror group 7 is the object plane 9 of the optical system, and the right side of the rear fixed mirror group 2 is the optical The image plane 1 (focal plane) of the system; the entrance pupil 8 of the optical system is fixed on the left side of the front fixed lens group 7 and on the right side of the object plane 9, and the front and rear positions are stable during zooming; the variable power lens group 6 and the light The diaphragm 3, the front fixed mirror group 7, the compensation mirror group 5, the relay mirror group 4 and the rear fixed mirror group 2 together constitute a complete imaging system.

[0070] The variable power mirror group 6 and the compensation mirror group 5 can mov...

Embodiment 2

[0132] The difference from Embodiment 1 is that: Figure 7 As shown, the first plane mirror 10 is set between the first negative lens 703 and the third positive lens 704; the second plane mirror 11 is set between the thirteenth positive lens 204 and the image plane 1; each lens surface type The parameter value remains the same, the position is adjusted accordingly, Figure 7 Among them, figure a is a schematic diagram of lens group distribution under telephoto, and figure b is a schematic diagram of lens group distribution under short focus. The plane mirror can change the propagation direction of the light beam, compress the volume of the entire optical system, and further realize miniaturization and dexterity. In other embodiments, only the first plane mirror 10 or only the second plane mirror 11 can be provided .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com