Soft sensing method for butane content in a dealanizer based on stacking

A technology of butane and soft measurement of a butane tower, applied in the field of industrial process prediction and soft measurement, can solve problems such as the inability to make good use of the Stacking model, and achieve the effect of improving the accuracy of real-time prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045]The present invention is described below in conjunction with a concrete butane content prediction embodiment of the butane tower:

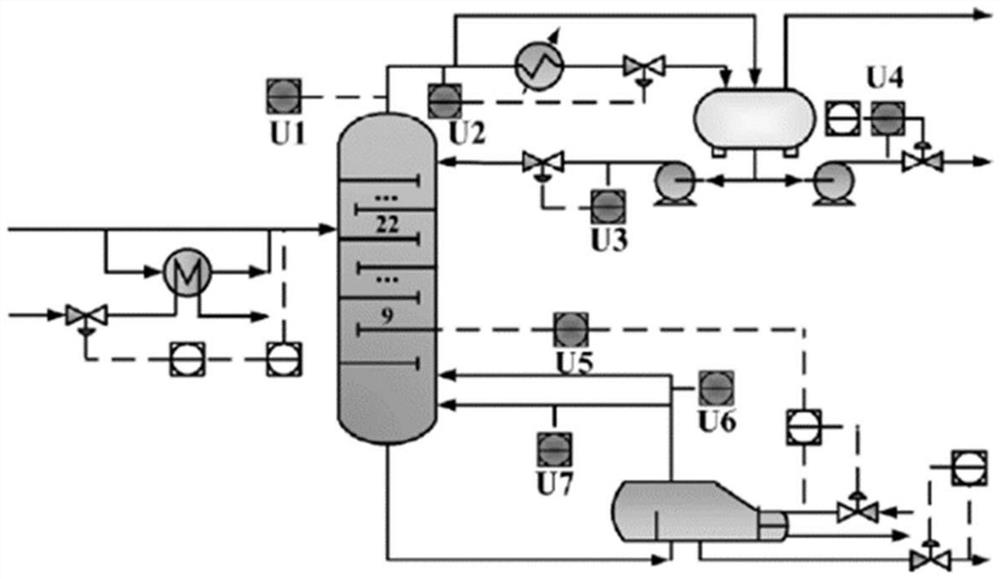

[0046] The first 1596 samples are used as the training set to train the integrated learning soft sensor model, and the last 798 samples are used as the test set to verify the performance of the integrated learning soft sensor model. effectiveness. In this process, seven process variables are selected to model the butane content at the bottom of the debutanizer, these seven process variables are the top temperature, top pressure, reflux, flow to the next stage, sixth Block plate temperature, column bottom temperature 1, column bottom temperature 2, such as figure 1 shown in.

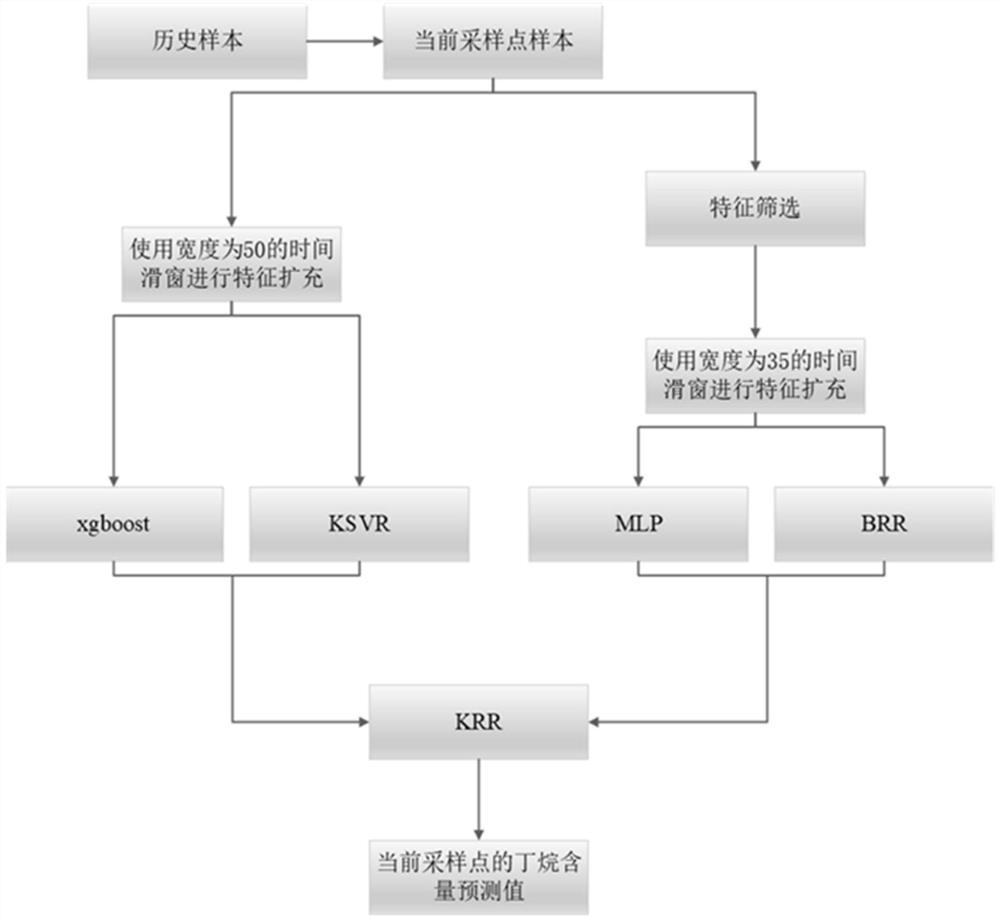

[0047] Next, the implementation steps of the present invention will be described in detail in combination with the specific process, such as image 3 shown, specifically:

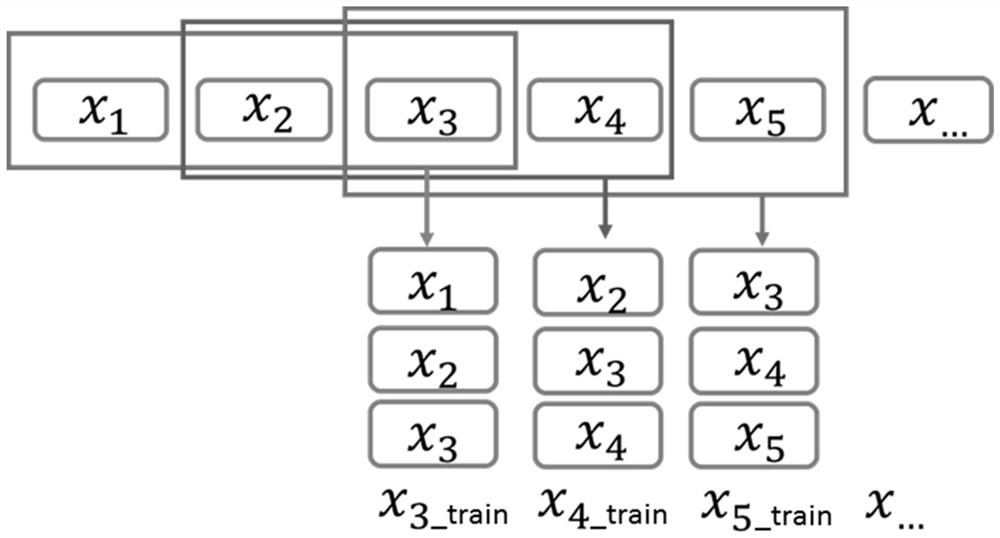

[0048] 1. Use 1596 training samples to train an XGBOOST regression model, and obtain the impo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com