Method for minimizing material mixing during transitions in a material processing system

A transitional, minimization technology, applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning devices, etc., can solve problems such as cost and achieve the effect of minimizing mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

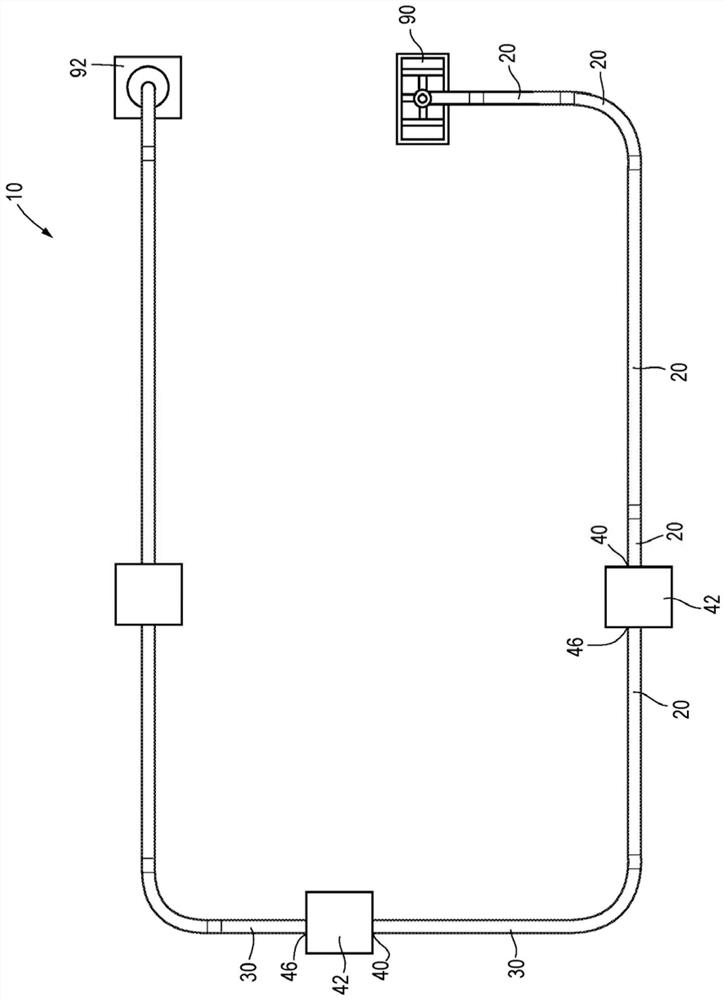

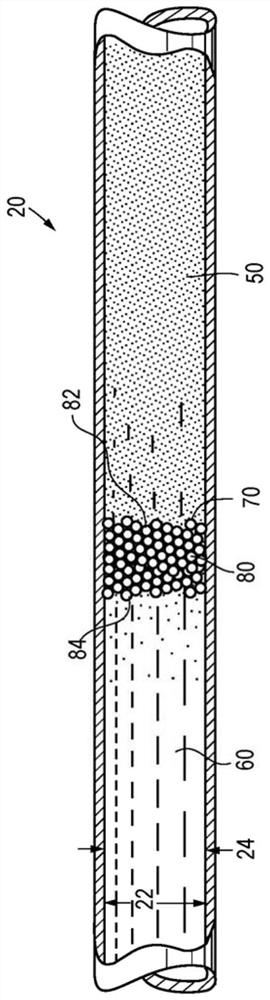

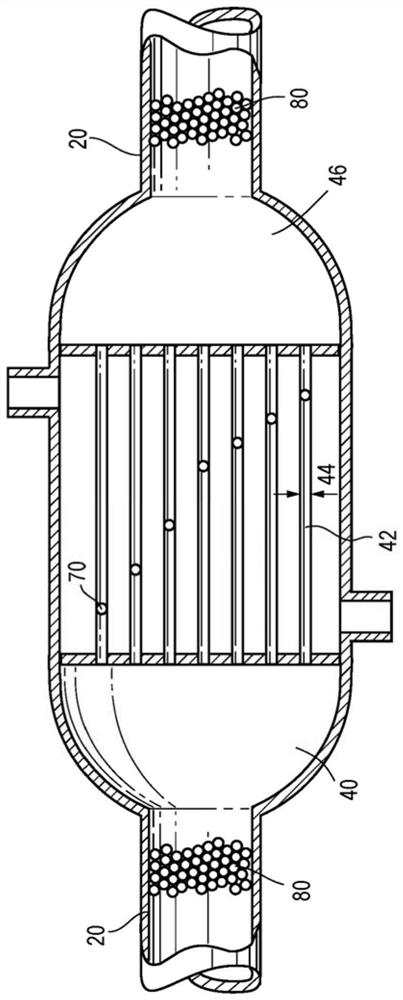

[0034]The present disclosure provides various embodiments of material handling piping that may be used in material handling and / or form part of a system for material handling. In this specification, elements or parts of a piping system are referred to as pipes, pipes, pipe sections or conduits. The inner surface is called the pipe wall or pipe wall. Piping systems can be used on a variety of materials including but not limited to solid, semi-solid and liquid such as but not limited to food and non-food related products such as edible and inedible food including meat, pastes, sauces, grains, vegetables, fruits , dairy products, cosmetics, pharmaceuticals, etc.

[0035] In general, material handling systems can be used to process one or more different types of products, so it is often necessary to clean or flush the material handling system before new material can be processed. The disclosed method advantageously enables the transition between a material being processed and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com