Adjustable intelligent processing equipment for jewelry inlaying

An intelligent processing and adjustable technology, applied in jewelry, etc., can solve the problems of clamping block conversion, poor clamping effect, sliding jewelry, etc., to achieve the effect of ensuring stability, facilitating processing, and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

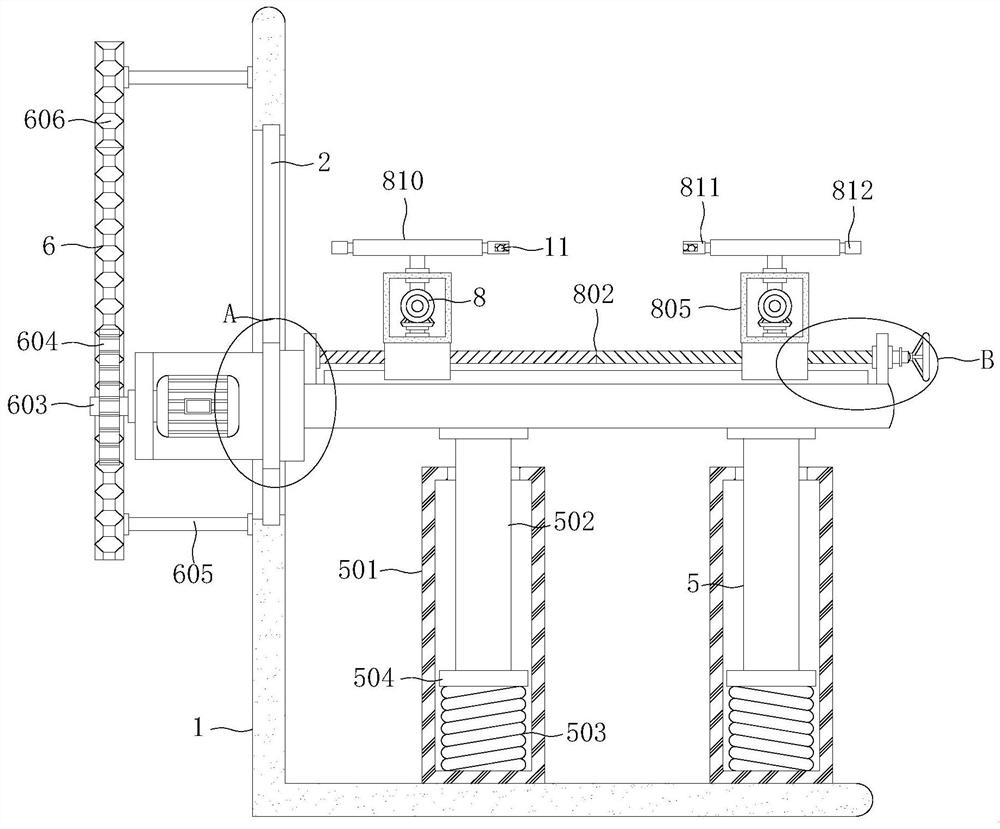

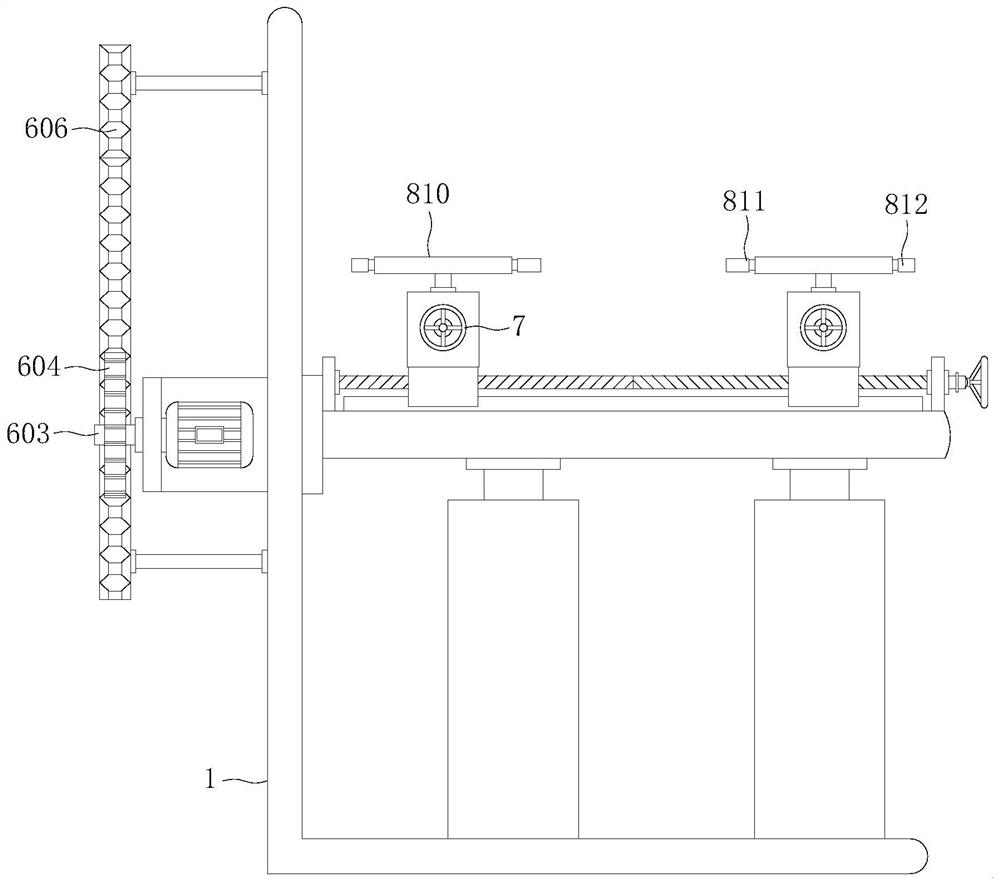

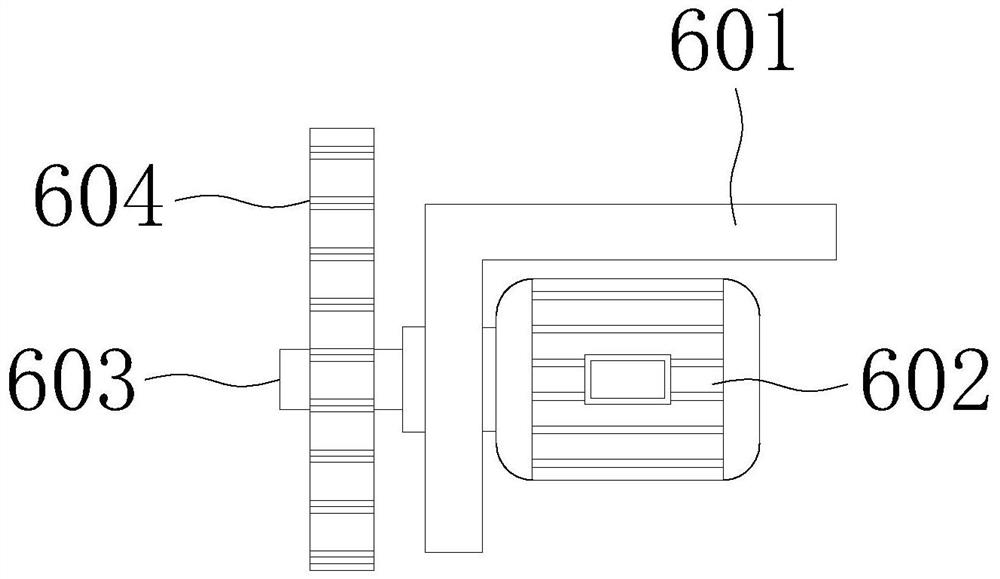

[0030] see Figure 1-7 , the present invention provides a technical solution: an adjustable intelligent processing equipment for jewelry inlay, including a work frame 1, a support mechanism 5, a lifting mechanism 6 and a control mechanism 8, and a chute is provided on one side of the work frame 1 2. Slider 3 is slidingly installed inside the chute 2, and processing plate 4 is fixedly installed on one side of the outer wall of slider 3. The supporting mechanism 5 is vertically arranged under the processing plate 4 in two groups, and the lifting mechanism 6 is installed horizontally. On one side of the work frame 1, the lifting mechanism 6 can drive the slider 3 and the processing plate 4 to move longitudinally relative to the work frame 1, and the control mechanism 8 includes an adjustment assembly and a conversion assembly, and the adjustment assembly can drive the conversion assembly to move laterally.

Embodiment 2

[0032] see Figure 1-7 , on the basis of Embodiment 1, the support mechanism 5 includes a sleeve 501, a lifting column 502, a spring 503 and a limit block 504, the sleeve 501 is fixedly installed on the inner top of the work frame 1, and the lifting column 502 is fixedly installed on the processing plate 4, the top of the sleeve 501 has an opening, one end of the lifting column 502 extends to the inside of the sleeve 501, one end of the spring 503 is fixed on the inner top of the sleeve 501, and the limit block 504 is fixed on the lifting column 502 The bottom end of the spring 503 is fixedly connected with the bottom of the limit block 504, and the processing plate 4 is supported and damped. On the one hand, the processing plate 4 can be supported and limited to ensure the stability of the processing plate 4. On the other hand, it can play a role of shock absorption in the lifting process of the processing plate 4, increasing the practicability of the processing equipment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com