Belted layer buffer film manufacturing device, control system and control method

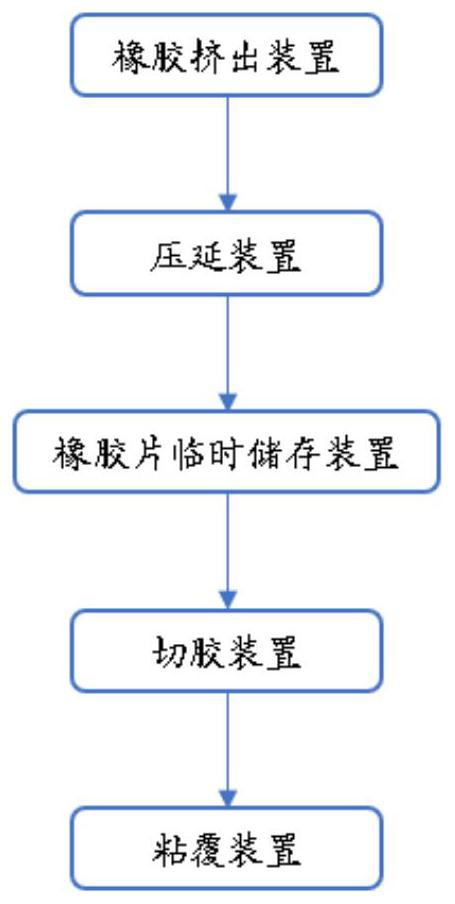

A technology for manufacturing devices and buffer films, which is applied in the field of tire manufacturing, can solve problems such as hardening and cooling, and achieve the effects of avoiding delamination, improving adhesion, and improving plasticity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

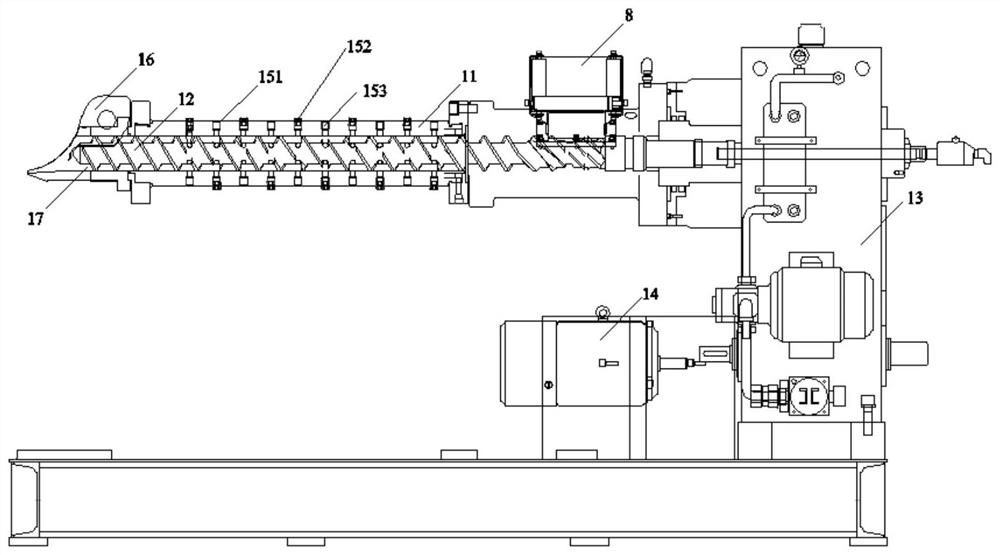

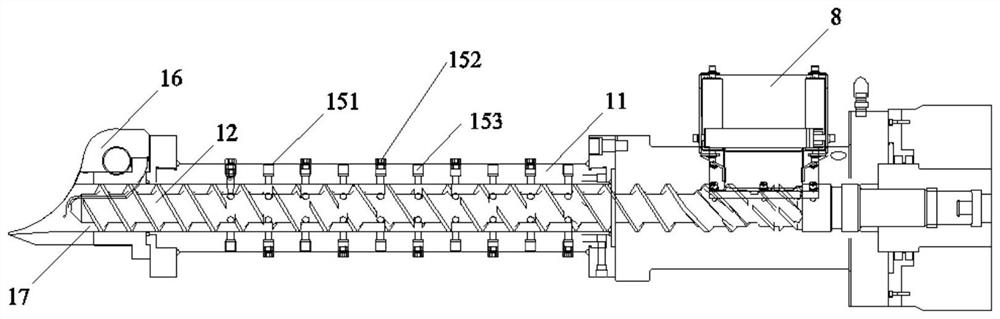

[0069] Hereinafter, the detailed structure of each part of this belt cushion film manufacturing device will be described through Embodiment 1.

[0070] Described extruder comprises machine barrel 11, single-screw structure 12 first reduction box 13 and machine head 17, as Figure 2-4 As shown, the rubber raw material enters from the rubber raw material inlet 8, and is extruded through the barrel 11 and the single screw 12. The upper structure of the single screw 12 has a saw-toothed helix. The head of the single screw structure 12 is connected with the first reduction box by splines. The first reduction box 13 has a first circular shaft, a second circular shaft, and a third circular shaft. Fourth circular axis. The first gear is arranged on the first circular shaft, the second gear and the third gear are arranged on the second circular shaft, the fourth gear and the fifth gear are arranged on the third circular shaft, and the sixth gear is arranged on the fourth circular shaf...

Embodiment 2

[0084] Further, due to the stirring action of the high-speed rotating single screw 12 and the internal pins of the barrel 11 on the rubber material, the temperature of the rubber material will increase, thereby increasing the possibility of air bubbles in the rubber sheet made of the rubber material. In view of this, an embodiment of the present invention provides a manufacturing device for a belt buffer film, which also includes:

[0085] Cooling device 3, the cooling device 3 is used to press the calendering device 2 to cool the rubber sheet of the first thickness to the first temperature, the cooling device 3 is as Figure 12 As shown, six cooling drums 311-316 and six second motors 321-326 are included. The cooling drums 311-316 are made of stainless steel, and the outer surface in contact with the rubber sheet is made of stainless steel to prevent impurities from being mixed into the rubber sheet. There are interlayers in the cooling drums 311-316, and cooling circuits f...

Embodiment 3

[0088] Further, in order to avoid the problem of uneven thickness in the buffer film manufacturing process, in view of this, a temperature control system, an alarm system, a temperature control method, and an alarm method are provided. Specifically, the first pressure and / or the first temperature are determined based on the temperature and composition of the rubber raw material.

[0089] The manufacturing device of the belt buffer film is equipped with a control system, and the control system includes a controller, an interactive interface, a readable storage medium, a bus and a display.

[0090] The temperature control system includes a first temperature control system and a second temperature control system, the first temperature control system is used to control the temperature of the extrusion device, and the second temperature control system is used to control the temperature of the calendering device , The temperature control system includes a heating loop and a cooling ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap