Flat fluorescent lamp

A fluorescent lamp, flat technology, applied to the parts of gas discharge lamps, etc., can solve the problems of poor productivity, high circuit design cost, and difficult to control the thickness of the dielectric layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

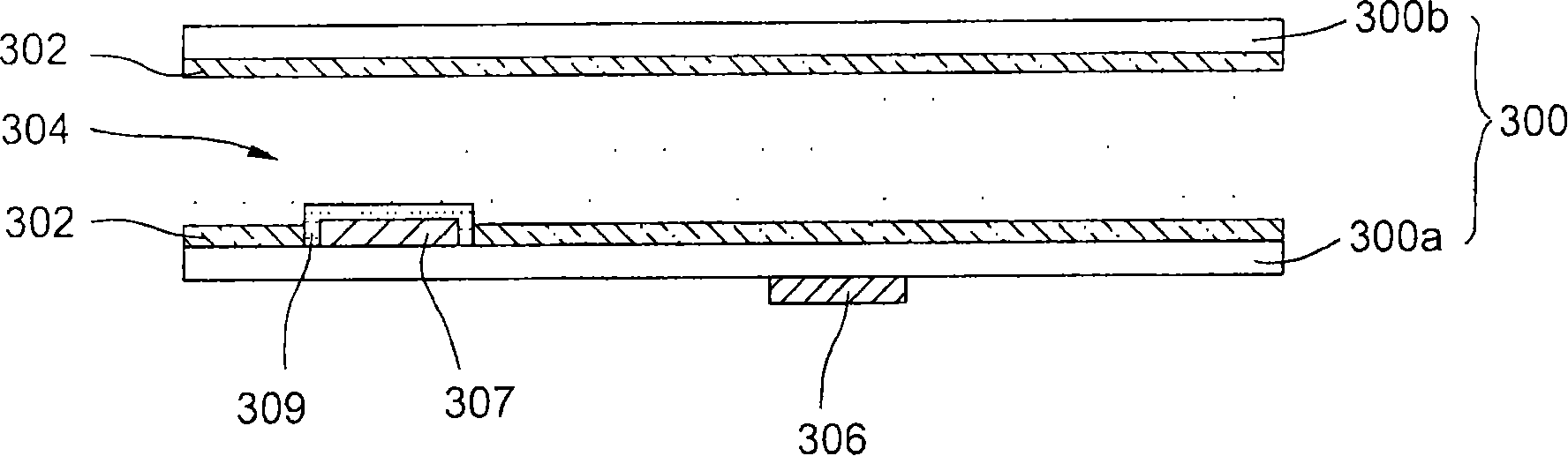

[0037] figure 2 A cross-sectional view showing a flat fluorescent lamp according to a first preferred embodiment of the present invention. Please refer to figure 2 The flat fluorescent lamp of this embodiment is mainly composed of a lower substrate 300a, an upper substrate 300b, a phosphor 302, a discharge gas 304, and a plurality of first electrodes 306 and second electrodes 307. Among them, a gas discharge chamber 300 is formed between the lower substrate 300a and the upper substrate 300b and is filled with a discharge gas 304; the first electrode 306 is located on the outer surface of the lower substrate 300a; the second electrode 307 is located on the inner surface of the lower substrate 300a and has a dielectric The layer 309 covers the second electrode 307 ; and the phosphor 302 is disposed on the inner wall of the gas discharge chamber 300 .

[0038] In this embodiment, since the paired electrodes 306 and 307 are located on different planes, the discharge area is la...

no. 2 example

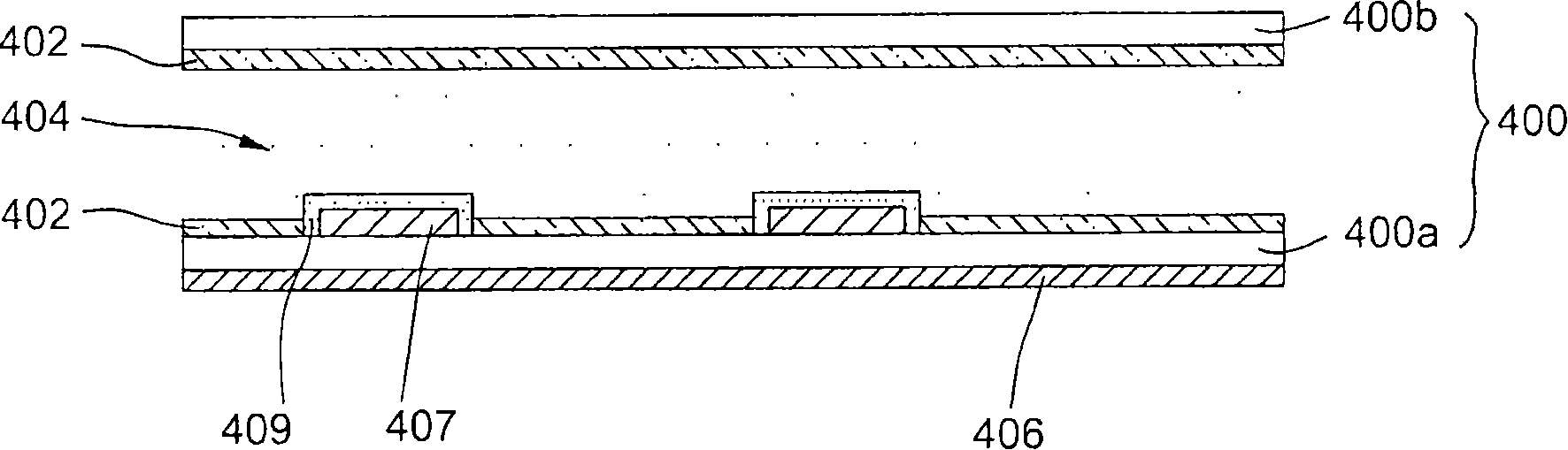

[0042] Figure 3AA cross-sectional view showing a flat fluorescent lamp according to a second preferred embodiment of the present invention. Please refer to Figure 3A , The flat fluorescent lamp of this embodiment is composed of a lower substrate 400a, an upper substrate 400b, a phosphor 402, a discharge gas 404, a first electrode 406 and a second electrode 407. In this embodiment, a gas discharge cavity 400 is formed between the lower substrate 400a and the upper substrate 400b and filled with discharge gas 404; the first electrode 406 is located on the outer surface of the lower substrate 400a; the second electrode 407 is located on the inner surface of the lower substrate 400a and covered with a dielectric layer 409 ; and the phosphor 402 is disposed on the inner wall of the gas discharge chamber 400 .

[0043] Figure 3B and Figure 3C A schematic diagram showing the change of the first electrode in the flat fluorescent lamp according to the second preferred embodimen...

no. 3 example

[0045] Figure 4 A cross-sectional view showing a flat fluorescent lamp according to a third preferred embodiment of the present invention. Figure 4 The flat fluorescent lamp shown includes a lower substrate 500 a , an upper substrate 500 b , a phosphor 502 , a discharge gas 504 , a first electrode 506 and a second electrode 507 . In this embodiment, a gas discharge cavity 500 is formed between the lower substrate 500a and the upper substrate 500b and is filled with a discharge gas 504; the first electrode 506 is located on the outer surface of the lower substrate 500a; and the second electrode 507 is formed inside the lower substrate 500a. The surface is covered with a dielectric layer 509; and the phosphor 502 is disposed on the inner wall of the gas discharge chamber 500;

[0046] In this embodiment, a carrier substrate 510 is disposed below the lower substrate 500a, and the carrier substrate 510 can optionally be attached to the lower substrate 500a with an adhesive 508 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com