Unitized prefabricated structure of luxury cruise ship cabin

A cabin unit and prefabricated structure technology, applied in the field of shipbuilding engineering, can solve the problems of high loss of manpower and material resources, increase the cycle of ship construction, inconvenience of prefabrication in advance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

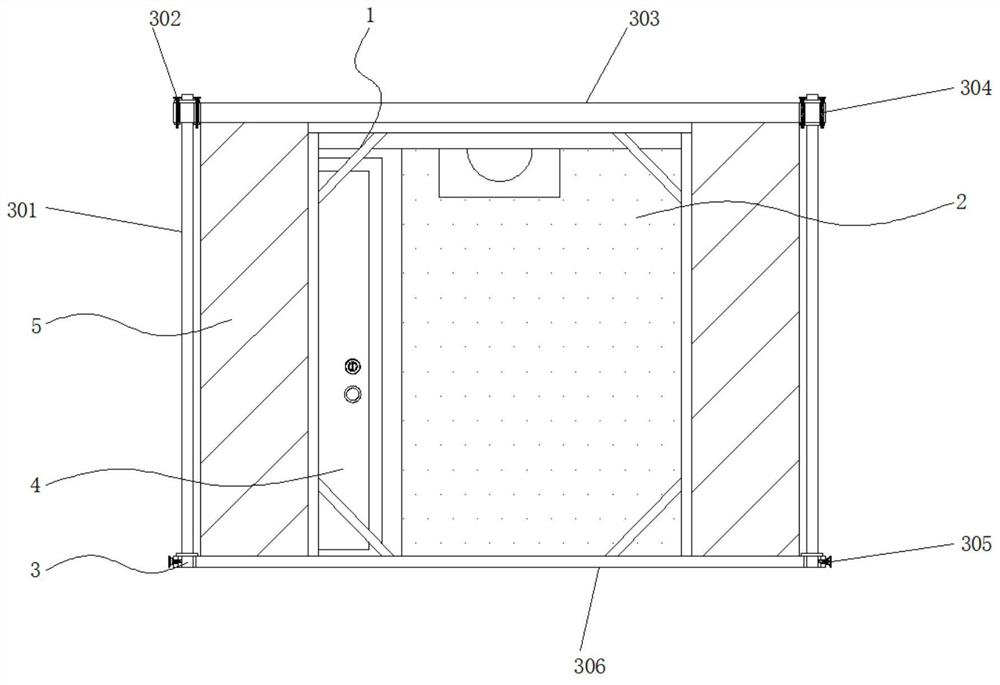

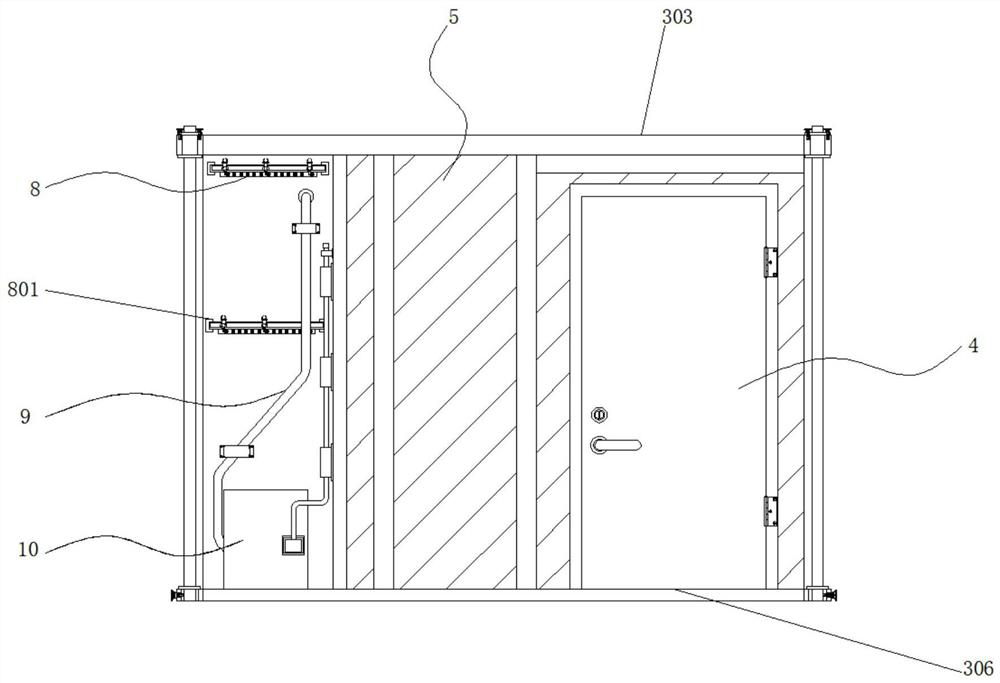

[0034] Example 1: See Figure 1-6, the unitized prefabricated structure of luxury cruise cabins, including a cabin unit main body 5, one end of the cabin unit main body 5 is fixedly connected with a unit frame 1, the outside of the cabin unit main body 5 is provided with a protective structure 3, and one end of the cabin unit main body 5 is fixedly connected with a The door panel 4 and the other side of one end inside the cabin unit main body 5 are fixedly connected with the cabin sanitary unit 2, the inner side wall of the cabin unit main body 5 is provided with a stable support structure 6, and the interior of the stable support structure 6 is provided with a sound insulation and noise reduction structure 7, The other end of the cabin unit main body 5 is provided with a wire harness structure 8, and the bottom of the outer end of the cabin unit main body 5 is fixedly connected with an electrical cabinet 10, and one side of the electrical cabinet 10 is fixedly connected with a...

Embodiment 2

[0037] Embodiment 2: The protective structure 3 is composed of a protective plate 301, fixing bolts 302, a top plate 303, a through groove 304, a limit bolt 305 and a bottom plate 306. The top plate 303 is fixedly connected to the top of the cabin unit main body 5, and the bottom plate 306 is fixedly connected to the cabin. The bottom end of the unit main body 5, the two sides inside the top plate 303 and the bottom plate 306 are fixedly connected with through grooves 304, and protective plates 301 are arranged between the through grooves 304, and six groups of protective plates 301 are arranged on both sides of the cabin unit main body 5, The protective plates 301 are arranged at equal intervals on both sides of the cabin unit main body 5, the two sides of the top of the protective plate 301 are provided with fixing bolts 302, and the side of the bottom of the fixing bolts 302 is provided with a limit bolt 305;

[0038] Specifically, such as figure 1 , figure 2 with Figur...

Embodiment 3

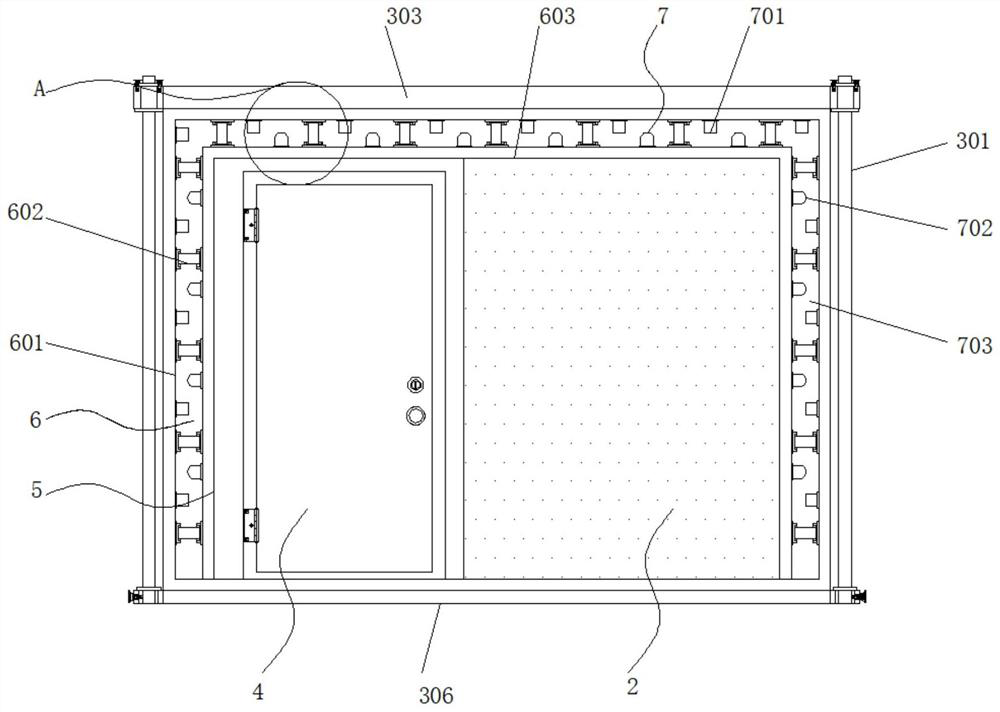

[0039] Embodiment 3: The stable support structure 6 is composed of an outer layer body 601, a reinforcing plate 602, an inner layer body 603 and a fixing seat 604. The outer layer body 601 is fixedly connected to the inner wall of the cabin unit main body 5, and the inside of the outer layer body 601 The inner layer body 603 is fixedly connected, the inner wall of the outer layer body 601 and the outer wall of the inner layer body 603 are fixedly connected with a fixing seat 604, and a reinforcing plate 602 is clamped between the fixing seats 604;

[0040] The outer layer body 601, the inner layer body 603 and the cabin unit main body 5 are on the same vertical plane;

[0041] Specifically, such as figure 2 with Image 6 As shown, the outer layer body 601 and the inner layer body 603 form a double-layer structure on the inner wall of the cabin unit main body 5, which strengthens the structural strength of the cabin unit body 5, and the fixing seat is passed between the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com