Automatic sand loading equipment

A technology for loading sand and equipment, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problem of needing labor for pockets, and achieve the effect of reducing operability and increasing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

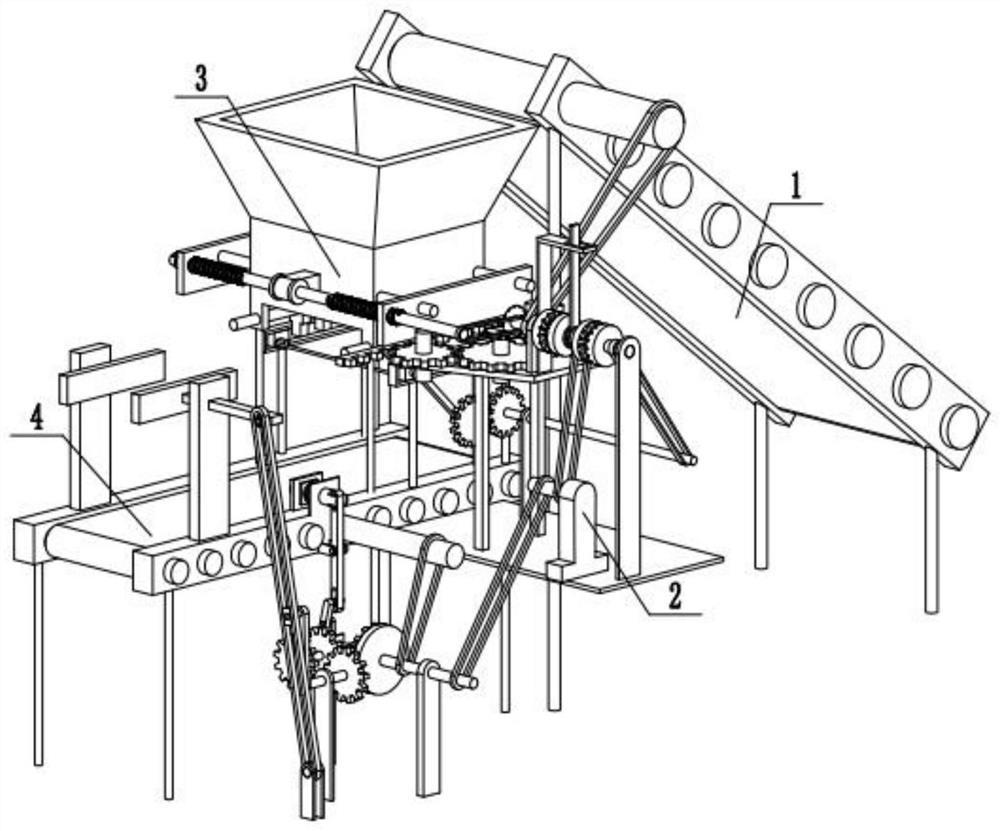

[0029] Combine below Figure 1-13 Describe this embodiment, an automatic sand loading equipment, including a feeding assembly 1, a bagging assembly 2, a bagging device 3, and a sealing device 4, the feeding assembly 1 is connected to the bagging device 3, and the bagging assembly 2 is connected to the bagging device The bagging device 3 is connected, the bagging assembly 2 is connected with the sealing device 4 , and the bagging device 3 is connected with the sealing device 4 .

specific Embodiment approach 2

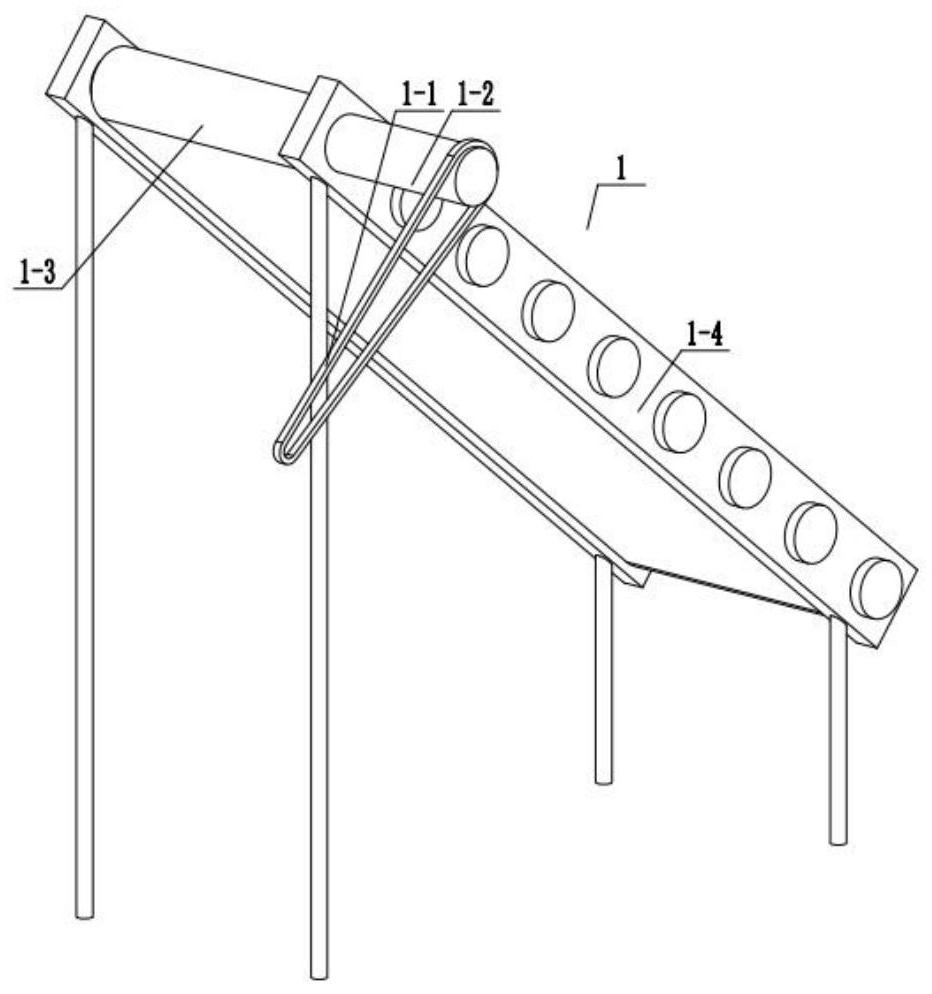

[0030] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the feeding assembly 1 includes a transmission belt 1-1, a roller 1-2, a conveyor belt 1-3, a feeding bracket 1-4, a transmission belt 1-1- 1 is connected with the roller one 1-2, the roller one 1-2 is connected with the conveyor belt one 1-3, and the roller one 1-2 is rotatably connected with the feeding bracket 1-4.

specific Embodiment approach 3

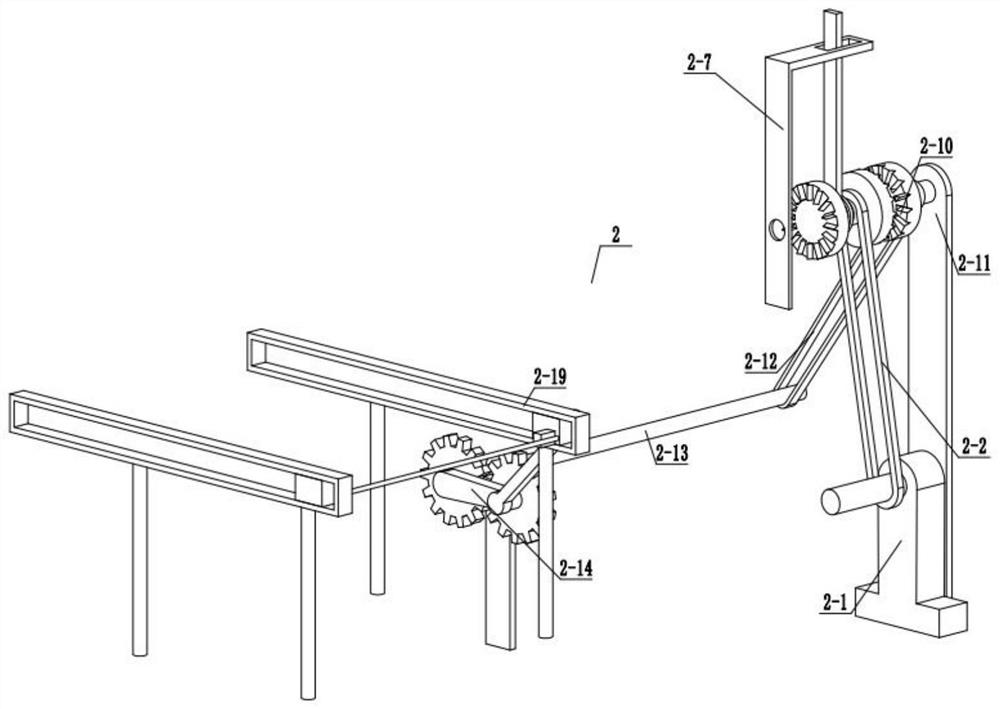

[0031] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 1. The bagging assembly 2 includes a motor 2-1, a transmission belt 2-2, a cross rod bearing 2-3, a cross rod 2-4, and a limit block 1 2-5, control rod 2-6, control rod bracket 2-7, clutch one 2-8, clutch two 2-9, clutch three 2-10, clutch bracket 2-11, transmission belt three 2-12, spur shaft One 2-13, rotating arm one 2-14, spur gear support one 2-15, spur gear one 2-16, connecting rod 2-17, bagging block 2-18, fixed chute 2-19, fixed rod One 2-20, the motor 2-1 is connected with the transmission belt two 2-2, the transmission belt two 2-2 is connected with the cross rod bearing 2-3, the cross rod bearing 2-3 is fixedly connected with the cross rod 2-4, and the limit Block one 2-5 is fixedly connected with cross rod 2-4, limit block one 2-5 is rotationally connected with control rod 2-6, control rod 2-6 is slidingly connected with control rod bracket 2-7, clutch one 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com