Automatic packaging equipment for textile printing and dyeing

A textile printing and dyeing and automatic technology, which is applied in the field of textile printing and dyeing, can solve the problems of lack of automatic packaging devices, etc., and achieve the effect of reducing operability and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

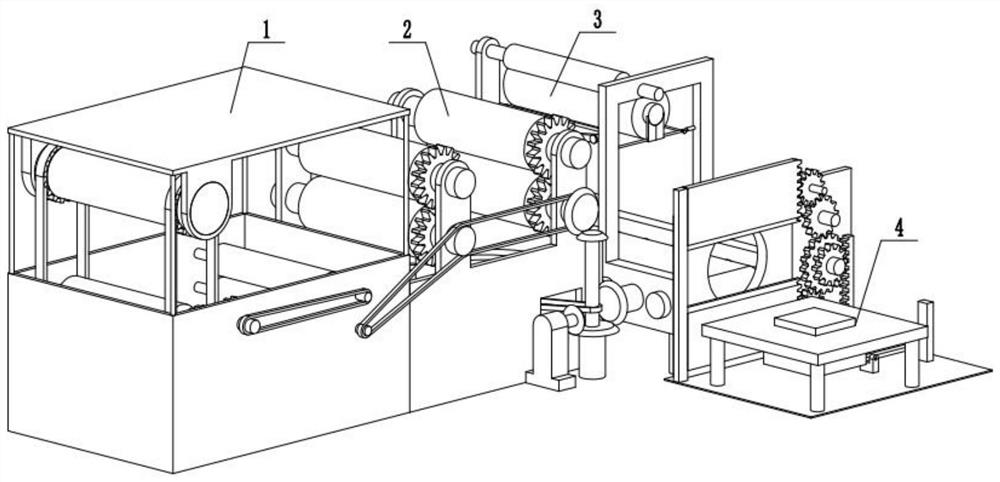

[0039] Combine below Figure 1-22 Describe this embodiment, an automatic packaging equipment for textile printing and dyeing, including a printing and dyeing assembly 1, a drying assembly 2, a loading assembly 3, and a packaging assembly 4, the printing and dyeing assembly 1 is connected to the drying assembly 2, and the drying assembly 2 is connected to the loading assembly 3-phase connection.

specific Embodiment approach 2

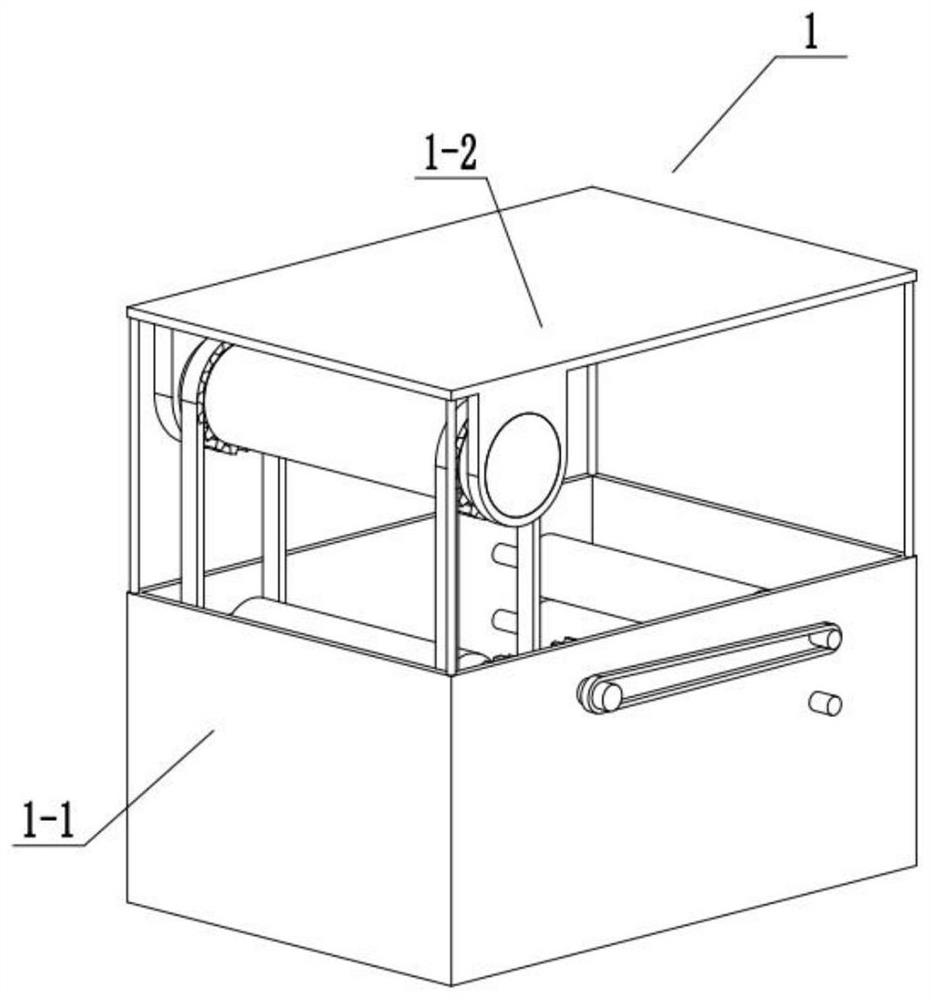

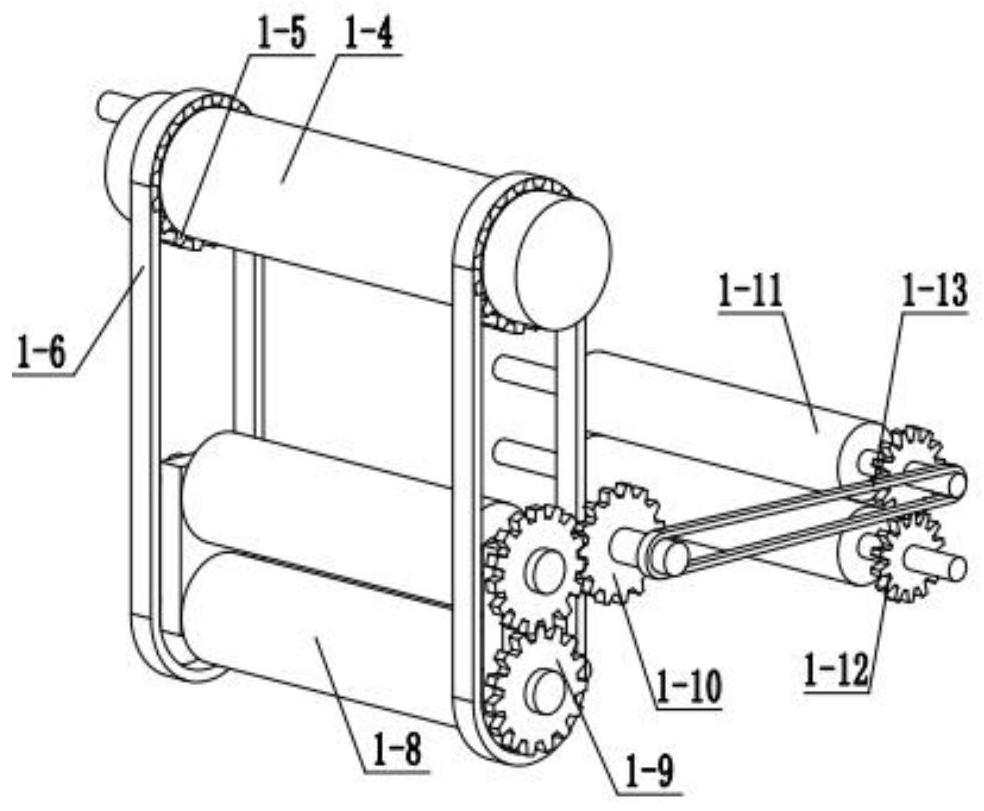

[0041] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain Embodiment 1, the printing and dyeing assembly 1 includes a printing and dyeing box 1-1, a printing and dyeing box fixing bracket 1-2, a rotating armrest 1-3, a roller 1-4, and a gear 1 -5, chain 1-6, fixed block 1-7, printing and dyeing rod one 1-8, gear group one 1-9, gear shaft one 1-10, printing and dyeing rod two 1-11, gear group two 1-12, transmission belt One 1-13, the printing and dyeing box 1-1 is fixedly connected with the printing and dyeing box fixing bracket 1-2, the rotating handrail 1-3 is fixedly connected with the roller one 1-4, and the roller one 1-4 is fixedly connected with the printing and dyeing box fixing bracket 1-2 Rotation connection, roller 1-4 is fixedly connected with gear 1-5, gear 1-5 is meshed with chain 1-6, chain 1-6 is fixedly connected with fixed block 1-7, fixed block 1-7 is connected with printing and dyeing rod One 1-8 is rotationally connec...

specific Embodiment approach 3

[0044] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain Embodiment 1, the drying assembly 2 includes a drying box 2-1, a drying rod 2-2, a gear set 3 2-3, a drying rod 2 2- 4. Gear group four 2-5, transmission belt two 2-6, bevel gear one 2-7, fan sleeve 2-8, fan shaft 2-9, fan blade 2-10, drying box 2-1 and drying Rod one 2-2 is rotationally connected, drying rod one 2-2 is fixedly connected with gear set three 2-3, drying rod two 2-4 is rotationally connected with drying box 2-1, drying rod two 2-4 is connected with Gear group 4 2-5 is fixedly connected, transmission belt 2 2-6 is connected with printing and dyeing rod 2 1-11, transmission belt 2 2-6 is connected with drying rod 1 2-2, transmission belt 2 2-6 is connected with drying rod 2 2-4 fit connection, bevel gear 1 2-7 is fixedly connected with drying rod 2 2-4, fan sleeve 2-8 is fixedly connected with drying box 2-1, fan sleeve 2-8 is connected with fan shaft 2- 9 is rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com