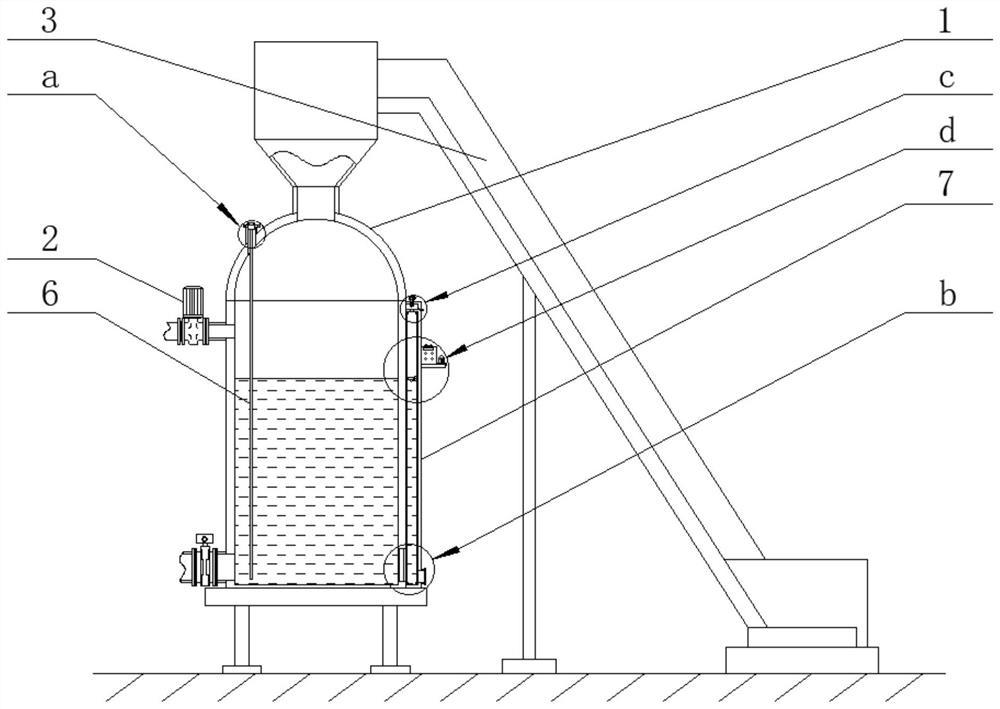

Emergency device for detecting liquid level of material storage tank of cut stem feeding machine

A liquid level detection and emergency device technology, applied in the field of tobacco processing, can solve the problems of the controller miscontrolling the feeding machine and the liquid feeding pump, the inability to understand and solve the problem at the first time, and the economic loss, so as to achieve a reasonable structure and avoid economic losses. The loss on the high, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

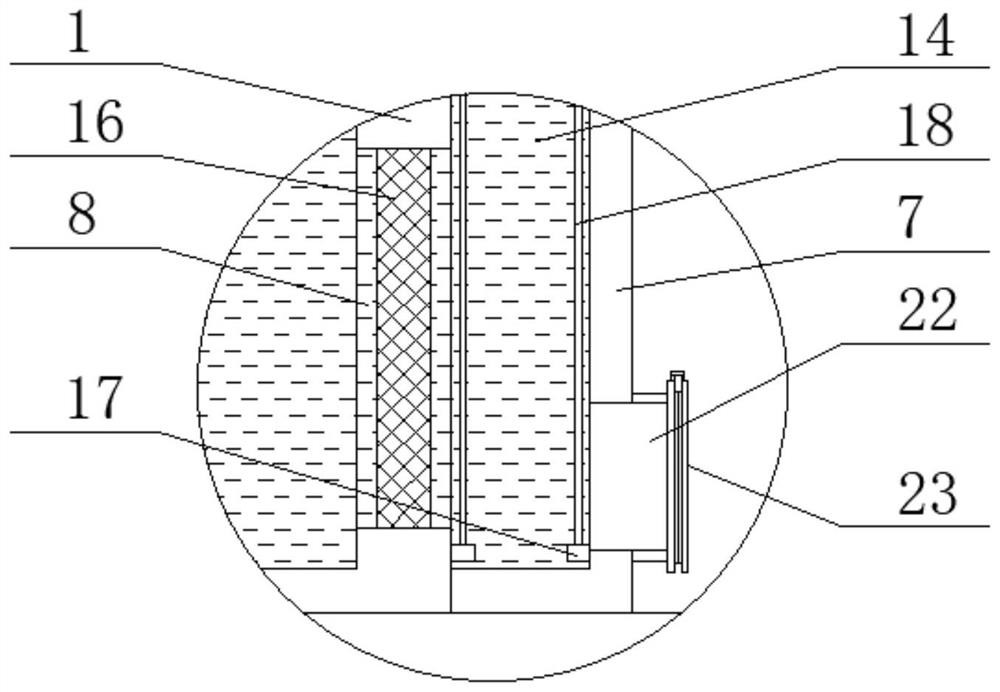

[0057] Another example Figure 4 and Figure 5 As shown, according to an embodiment of the present invention, the secondary detection mechanism includes a secondary detection box 7, a floating plate 9 and a laser rangefinder 10, the secondary detection box 7 communicates with the storage tank 1, and the floating plate 9 floats on the secondary detection box 7 inside the liquid surface.

[0058] The laser range finder 10 is arranged on the top of the auxiliary detection box 7, and the laser range finder 10 measures the distance between the floating plate 9 and the laser range finder 10, thereby converting the liquid level height.

[0059] During implementation, the liquid in the storage tank 1 flows into the secondary detection box 7 from the opening 8, and the floating plate 9 gradually rises under the buoyancy of the liquid, and the laser distance meter 10 detects the distance between the floating plate 9 and the floating plate 9 in real time. , and convert the specific hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com