Novel damper backpressure device

A technology of back pressure device and damper, which is applied in the textile field, can solve the problems of manufacturing precision requirements and high cost, complicated installation and adjustment process, complicated mechanical structure, etc., and achieve the effect of low noise and vibration frequency, light weight and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

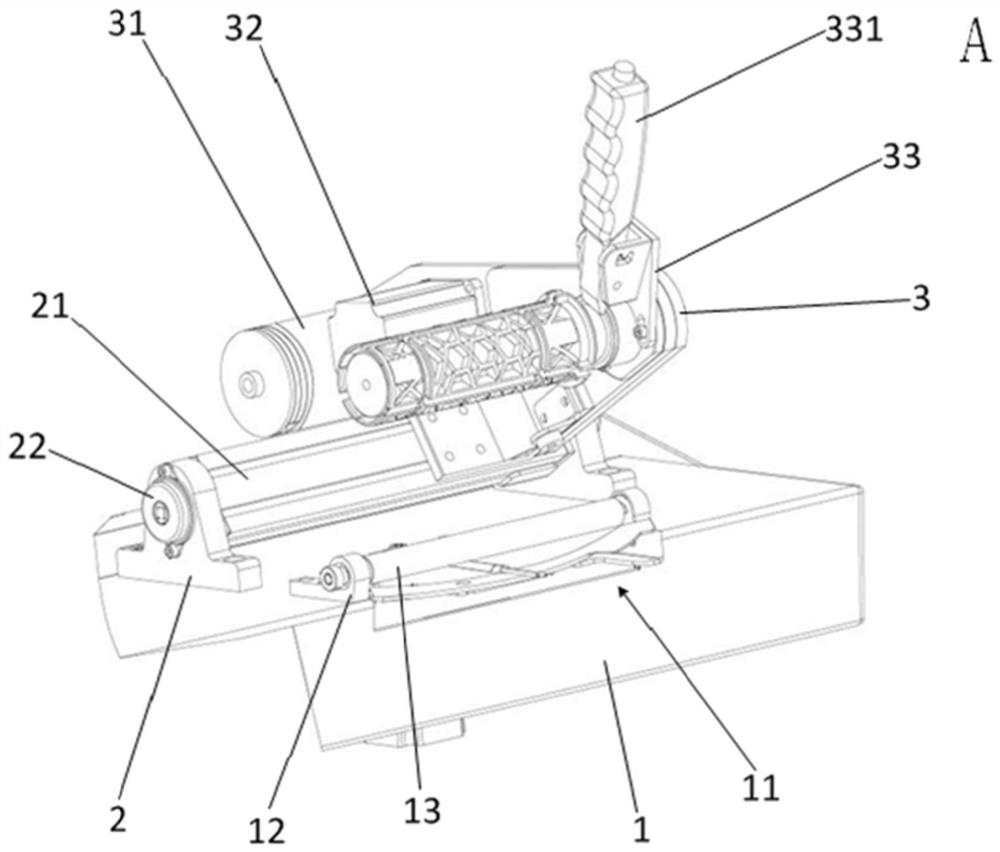

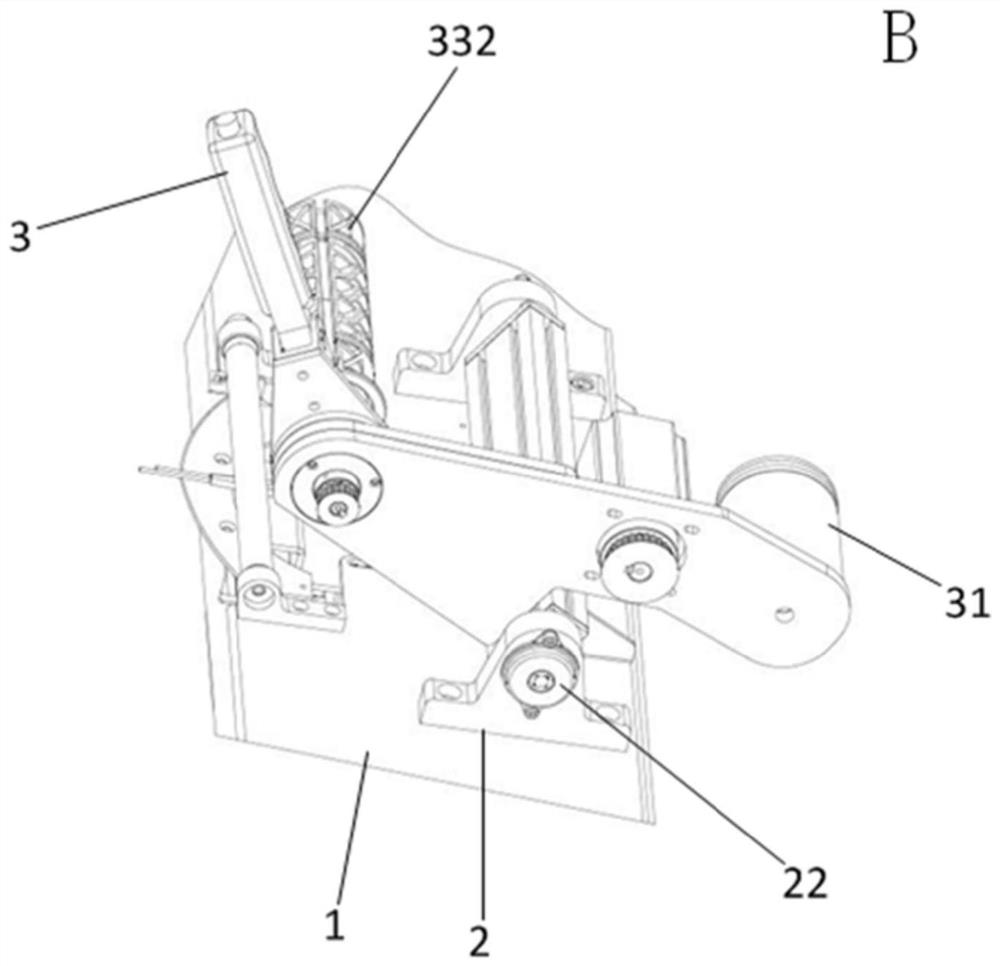

[0012] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments of the accompanying drawings.

[0013] like Figure 1-2 As shown, a new type of damper back pressure device according to the embodiment of the present invention includes a workbench 1, and the workbench 1 is provided with an installation groove 11, and the two sides of the installation groove 11 are located symmetrically on the upper surface of the workbench 1. A driven shaft fixing block 12 is provided, and the driven shaft fixing block 12 is directly provided with a driven shaft 13. The upper surface of the workbench 1 is located at the rear of the installation groove 11 and is laterally symmetrically provided with a rotating shaft fixing block 2. The rotating shaft A rotating shaft 21 is arranged between the fixed blocks 2, and dampers 22 are arranged symmetrically at both ends of the rotating shaft 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com