A flat-plate membrane element with uniform water production flux

A flat membrane, water flux technology, applied in membrane technology, semi-permeable membrane separation, biological water/sewage treatment, etc., can solve the problems of high energy consumption and operating costs, reduction of filtration area, cost waste, etc., to reduce investment cost, improve the overall level, and save the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

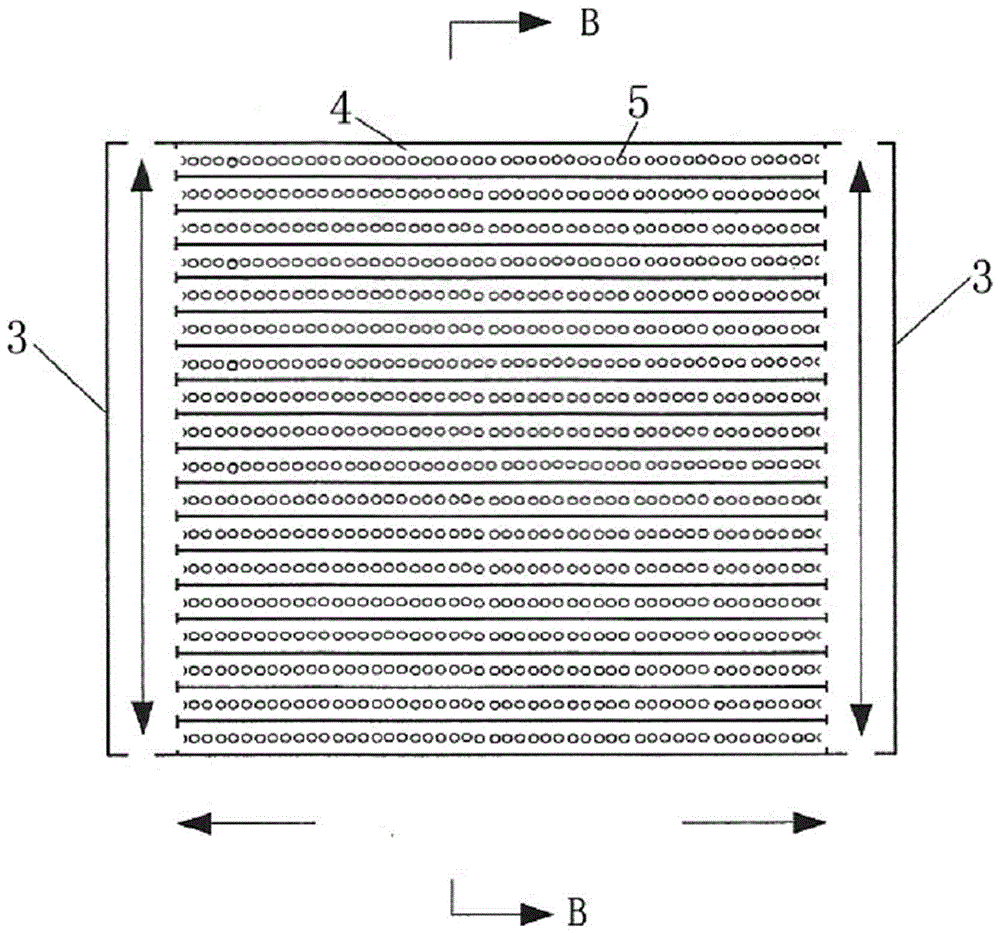

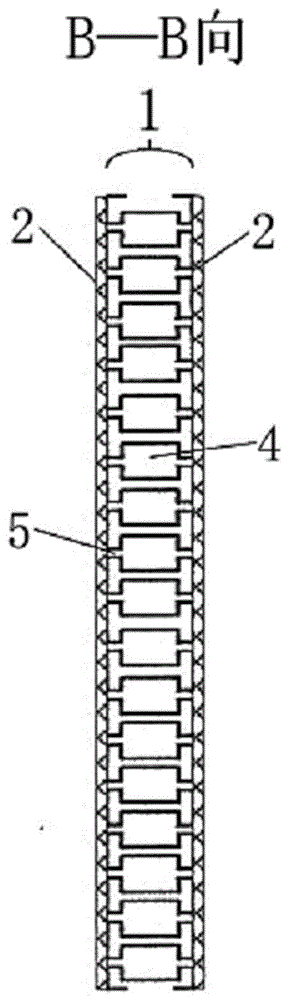

[0027] see figure 1 , figure 2 , the aperture of the current-limiting water-collecting hole 5 is 1mm, the cross-sectional area of each water-producing branch pipe 4 is 4mm×4mm, and the quantity of the single-sided current-limiting water-collecting hole 5 of a single water-producing branch pipe 4 is 100, and the hole spacing is 4mm , 200 water production branch pipes 4 are horizontally arranged, parallel to each other, isolated from each other, and converge into the vertical water production pipes on both sides. The cross-sectional area of the water production main pipe 3 is 40mm×5m.

[0028] In the specific implementation, general-purpose products are used, such as the substrate 1 is assembled by hollow board, Wantong board and injection molded parts, and the periphery of the two diaphragms 2 forms a closed flat plate with the substrate 1 by means of ultrasonic, hot-melt or glue. Membrane elements.

example 2

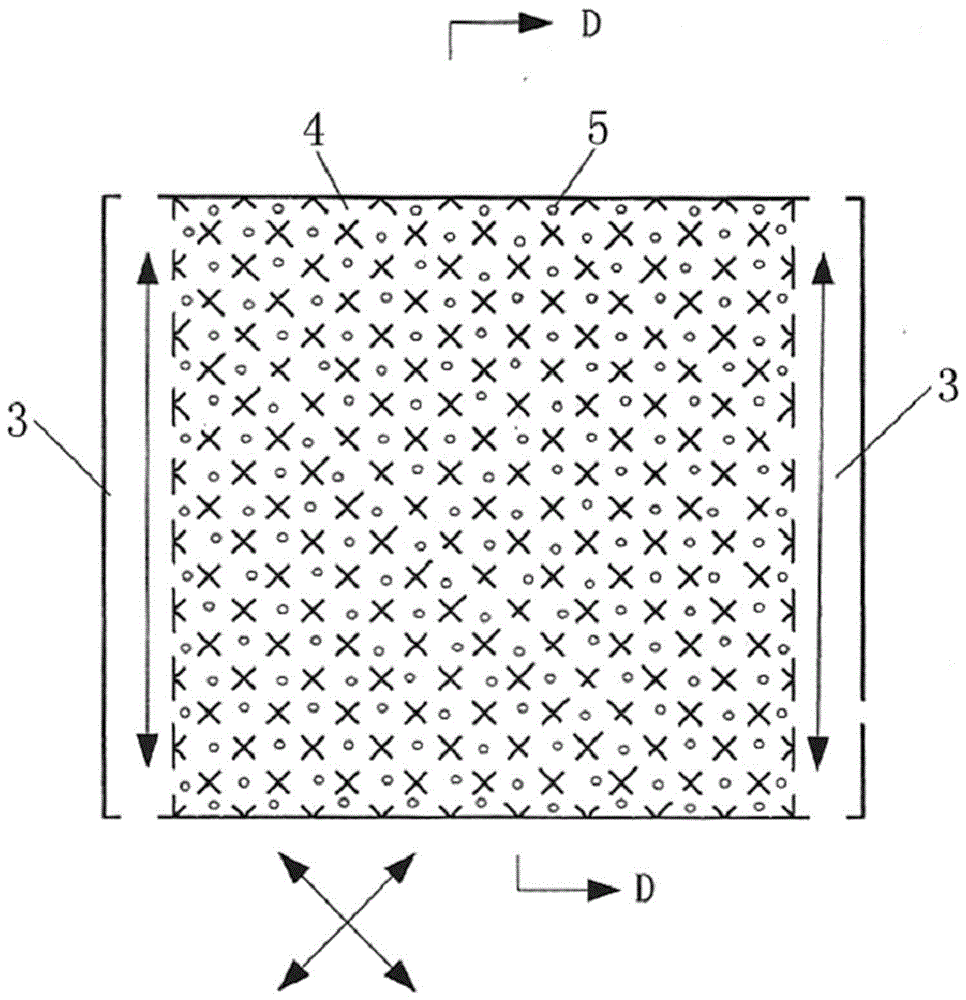

[0030] see image 3 , Figure 4 , the aperture of the flow-limiting water-collecting hole 5 is 1mm, and the cross-sectional area of each water-producing branch pipe 4 is 4mm×4mm. The water production branch pipes 4 are arranged obliquely, and 100 rows of water production branch pipes intersect and communicate with each other to form an "x" network. The water production branch pipes 4 are connected to the vertical water production main pipe 3 along a 45-degree direction. The cross-sectional area of the water production main pipe 3 is 40mm×5mm.

[0031] In specific implementation, existing products, such as heat-shrinkable and cold-fixed plastic filter screens and injection molded parts are used to assemble the substrate 1, and the peripheral edges of the two diaphragms 2 are formed with the substrate 1 by means of ultrasonic waves, hot-melt or glue. Closed flat membrane element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com