Waterproof membrane prepreg composition, waterproof membrane prepreg, preparation method and application thereof

A technology for waterproofing membranes and compositions, which is applied in building thermal insulation materials, roofs using flexible materials, building structures, etc. The performance of the joint and the effect of satisfying the oil permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

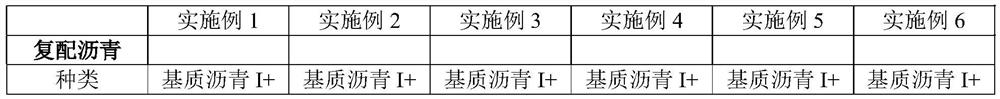

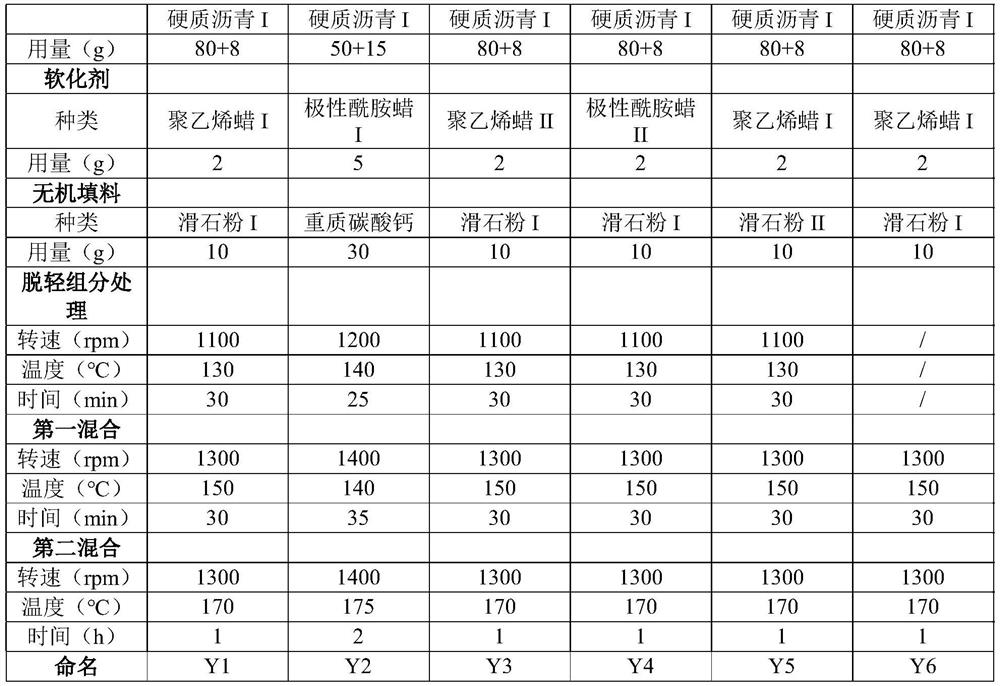

[0071] This example is used to illustrate that the waterproof membrane prepreg composition according to the present invention is prepared according to the formula and process parameters in Table 1, and the waterproof membrane prepreg is prepared according to the following method.

[0072] The preparation method of the waterproof roll material prepreg comprises the following steps:

[0073] (1) Stir the base asphalt at a speed of 1100 rpm at 130°C for 30 minutes to obtain delightened asphalt;

[0074] (2) Stirring the delightened asphalt, softener, and hard asphalt at a speed of 1300 rpm at 150°C for 30 minutes to obtain the first mixture;

[0075] (3) The first mixture and the inorganic filler were stirred for 1 hour at 170° C. at a speed of 1300 rpm to obtain a waterproof membrane prepreg Y1.

Embodiment 2

[0077] This embodiment adopts the same flow process as embodiment 1 to carry out, and the difference is that in this embodiment:

[0078] The formulations and process parameters of the waterproof membrane prepreg compositions used are different, see Table 1 for details.

[0079] The waterproof membrane prepreg Y2 was prepared.

Embodiment 3

[0081] In this example, a waterproof membrane prepreg was prepared using a formula and method similar to that of Example 1, except that polyethylene wax I was replaced with polyethylene wax II by equal weight to prepare a waterproof membrane prepreg Y3. See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com